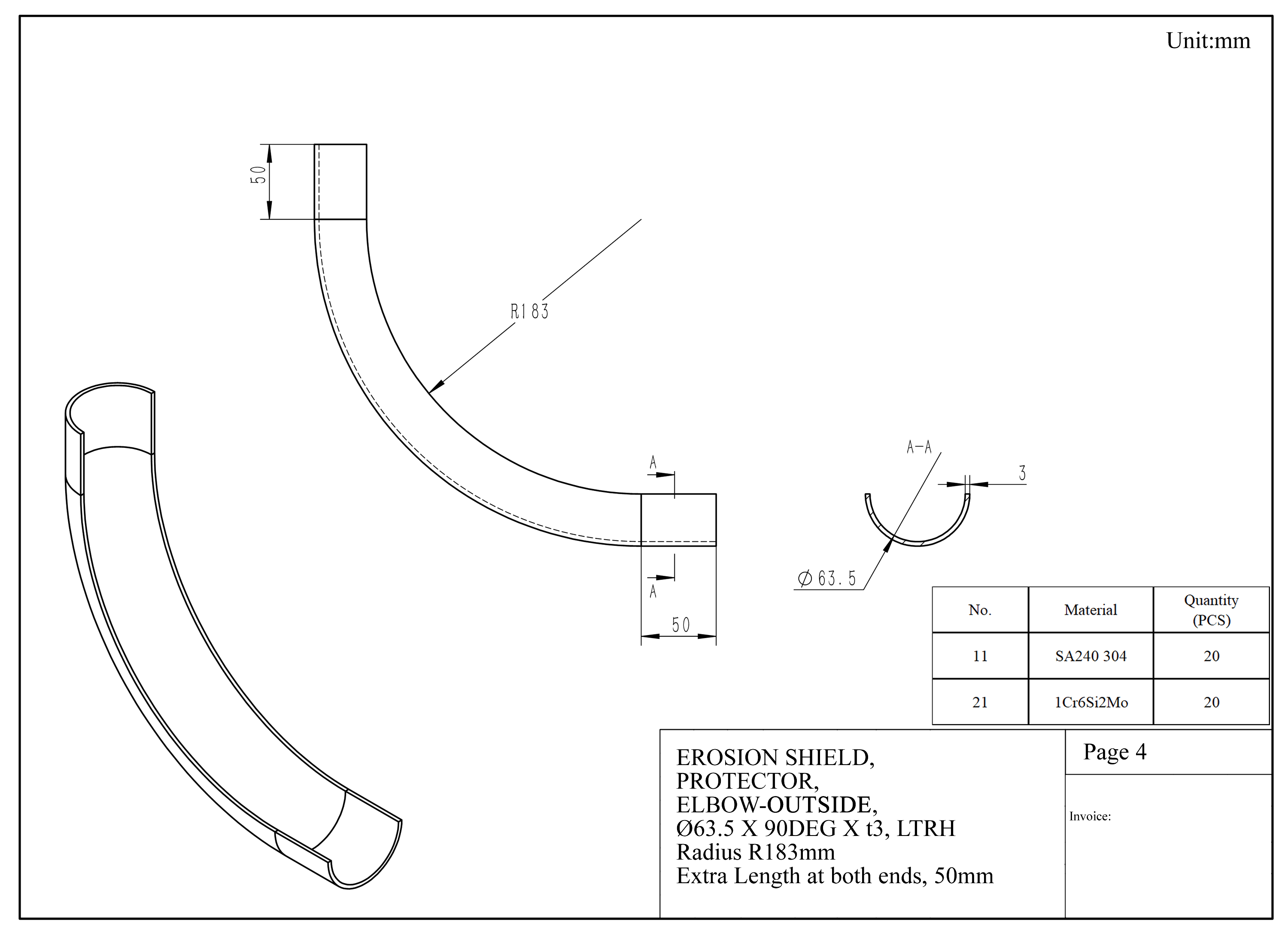

1Cr6Si2Mo erosion shield protector for elbow sections, featuring extra inside length for superior protection in boiler systems.

The 1Cr6Si2Mo erosion shield protector is specifically designed for elbow sections in industrial boiler systems. Featuring an extended inside length, it provides superior protection against erosion and wear in high-temperature and high-pressure environments.

Its excellent resistance to oxidation, corrosion, and wear makes it suitable for industries handling abrasive particles or corrosive mediums.

The 1Cr6Si2Mo Erosion Shield Protector Elbow is specifically designed for high-temperature and erosion-prone environments. Its excellent resistance to oxidation, corrosion, and wear makes it suitable for industries handling abrasive particles or corrosive mediums.

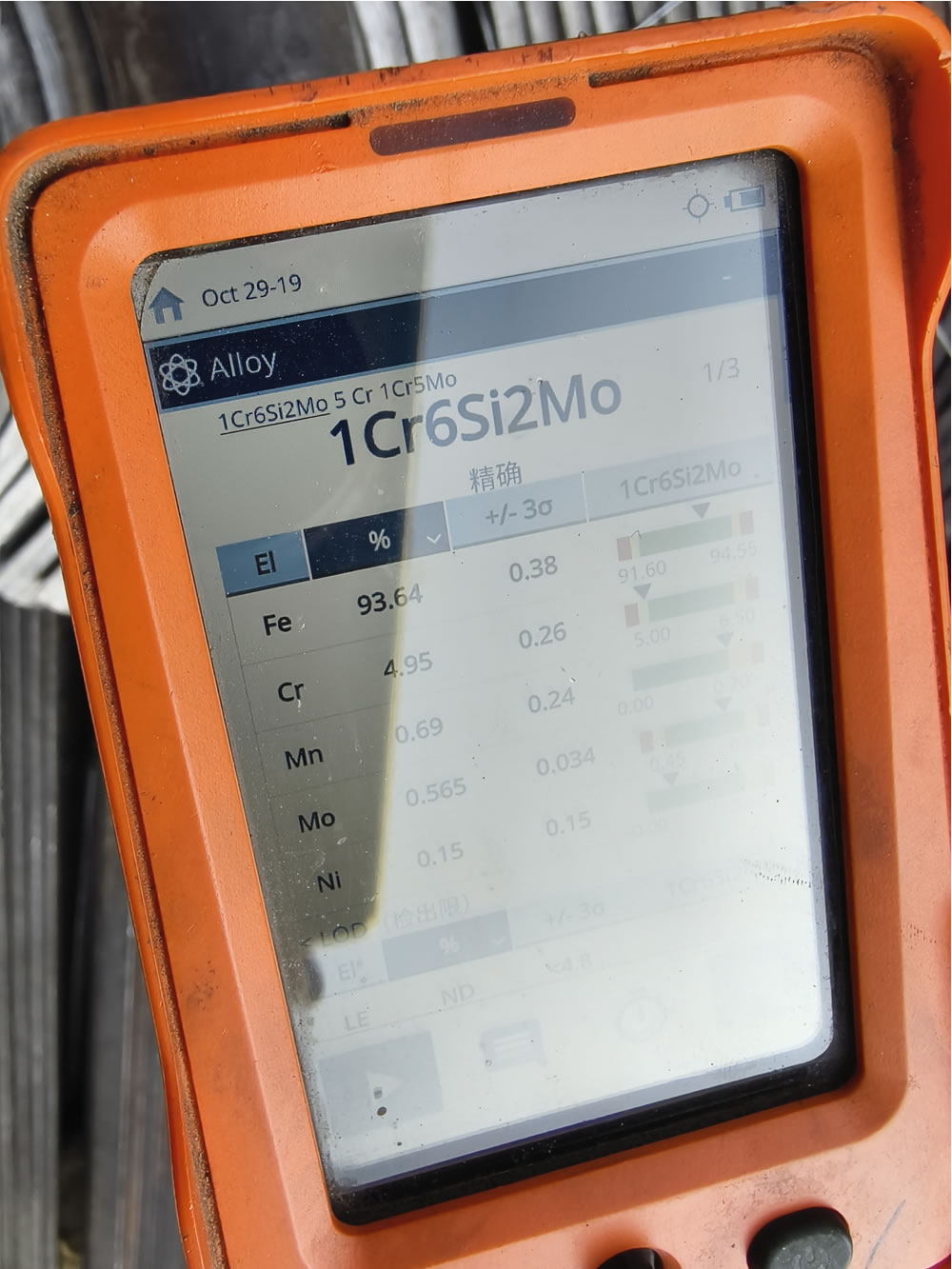

| Element | Content (%) |

|---|---|

| Carbon (C) | ≤ 0.15 |

| Silicon (Si) | 1.5 - 2.0 |

| Manganese (Mn) | ≤ 0.7 |

| Phosphorus (P) | ≤ 0.035 |

| Sulfur (S) | ≤ 0.030 |

| Chromium (Cr) | 5.2 - 6.0 |

| Molybdenum (Mo) | 0.45 - 0.6 |

1Cr6Si2Mo is a martensitic heat-resistant steel with good oxidation resistance at 800°C. Compared with 1Cr5Mo steel, since it contains 1.5% silicon (Si), the temper brittleness tendency of 1Cr6Si2Mo increases, and brittle fracture may occur when working at high temperatures for a long time. This material shows good corrosion resistance in sulfur-containing oxidizing atmospheres and hot petroleum media.

After normalizing and tempering heat treatment, 1Cr6Si2Mo has high creep strength and durability. In addition, 1Cr6Si2Mo has an air quenching phenomenon. If it cools too quickly after hot processing, cracks may occur, so slow cooling is required.

Its weldability is poor. Electric welding is recommended instead of gas welding. It needs to be preheated to 300°C - 400°C before welding and tempered at 750°C after welding.

| Property | Value |

|---|---|

| Tensile Strength | ≥ 547 MPa |

| Yield Strength | ≥ 401 MPa |

| Elongation | ≥ 31.5% |

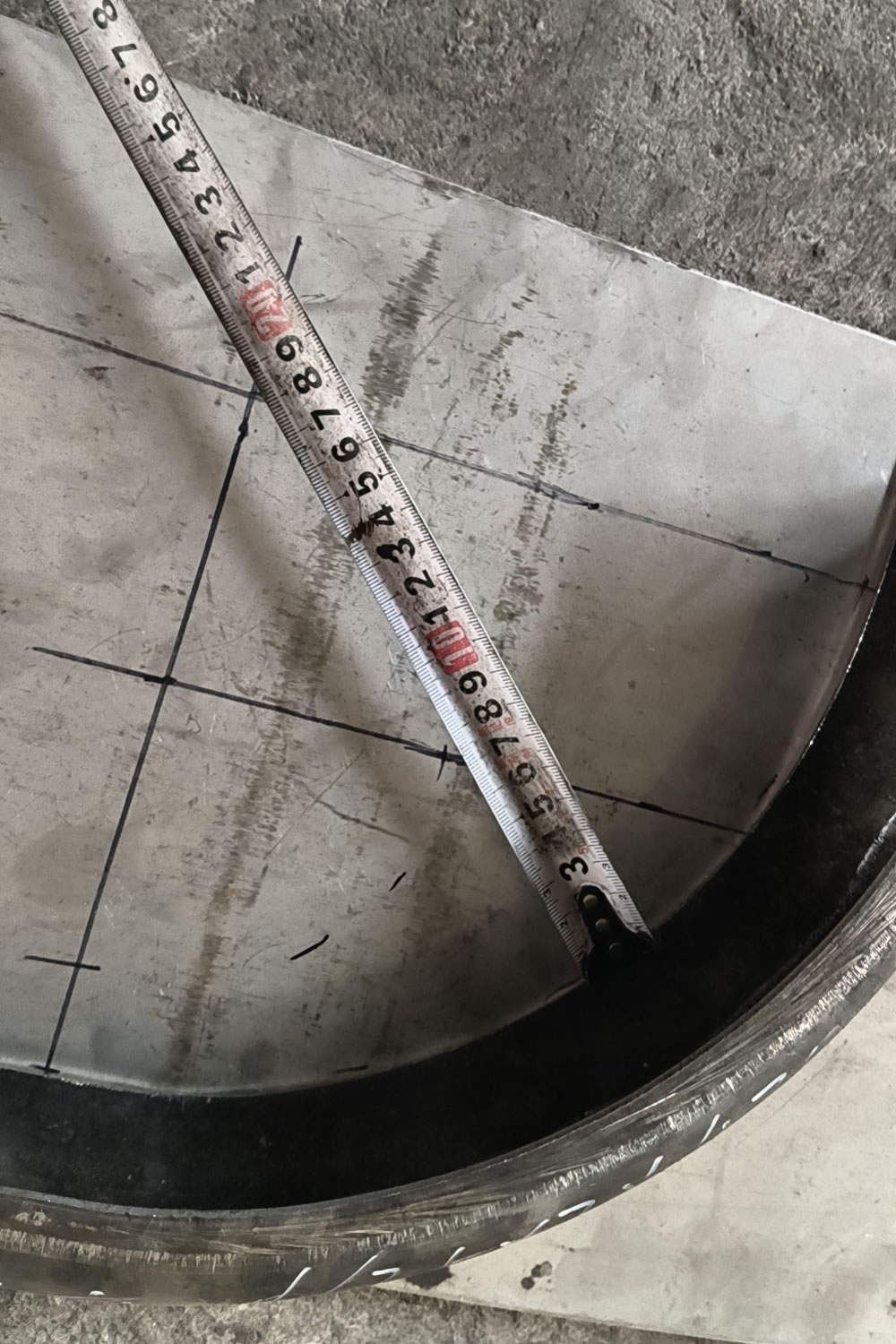

The protector elbow undergoes precise fabrication to ensure a snug fit and maximum protection. Welding preheating (300°C-400°C) and post-weld tempering (750°C) are recommended to maintain material properties and reduce residual stress. Custom dimensions are available for seamless integration into existing systems.

Tube shields are custom made to fit perfectly to straight sections, curved sections and even finned and specialised tubing.

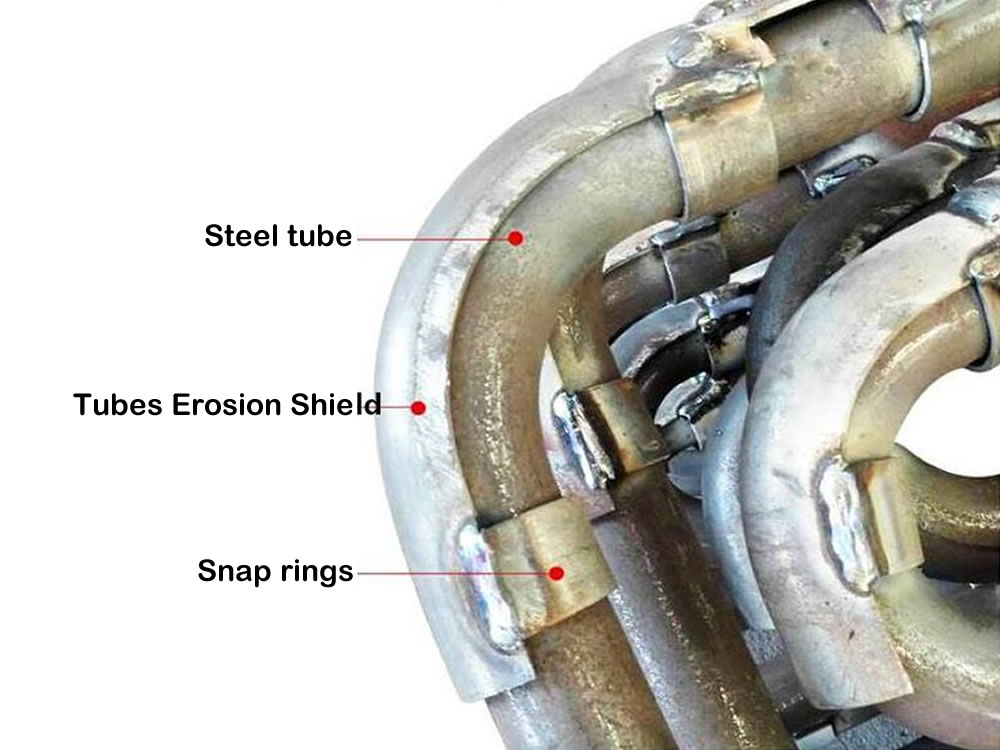

Boiler tube erosion shields, also known as anti-corrosion shields, anti-wear plate, anti-wear protection shields, anti-wear cover plate, anti-corrosion cover plate, boiler climbing pipe, anti-wear pressure plate, etc. , which are used in combination with snap rings.

Boiler tube erosion shields are produced using a high-pressure press and professional mould pressing. The production time is short, the welding performance is good, the welding should not fall off, the surface is smooth, and the appearance is beautiful. Boiler tube erosion shields with bends are formed by pressing on a press or bending with a special abrasive on a tube bender.

Boiler tube shields are designed to eliminate major maintenance and downtime costs from boiler and condenser tube failure.

Generally, boiler tubes erosion shields are also installed to prevent further wear of the tubes and cause serious consequences such as boiler explosion.

The main role is to protect the heating surface of the boiler pipes, reduce pipeline wear, and increase the heating surface of the pipes.

The snap ring is a short section that is installed on the pipe in conjunction with the wear-resistant tile. Generally, it is welded to the wear-resistant tile by lap welding, that is, to cover the wear-resistant tile slightly, so it is larger than the wear-resistant tile. The opening arc is around 190-200 degrees, the welding position needs to be set aside to facilitate welding and fixing. The width of the snap ring must not be less than 20mm.

The installation requirements of anti-friction tiles of different shapes are slightly different. Basically, each anti-friction tile is installed with not less than 2-4 snap rings. The snap ring and the anti-friction tile are welded together to prevent expansion due to heat. The tiles fall off, and the joints are required to be fully welded.