Rubber expansion joint

is a flexible connector to absorb noise, shock, vibration, physical and thermal energy.

These hoses are constructed from thin-walled stainless steel tubes that are formed, welded, and corrugated to add flexibility and strength.

Download PDF

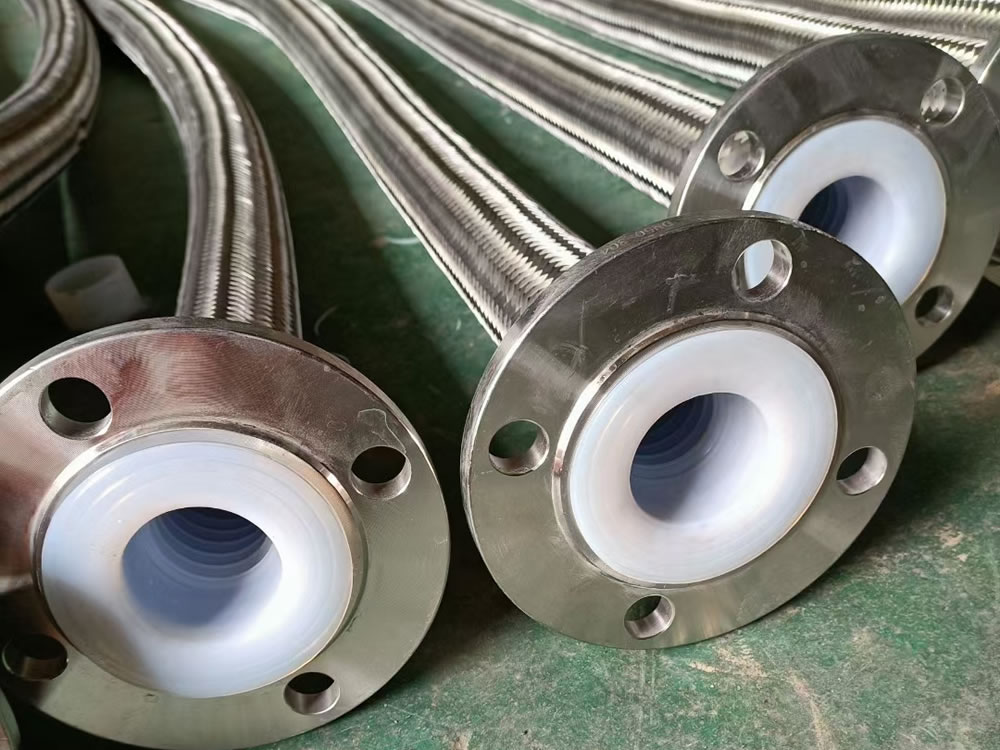

A PTFE lined hose represents an ideal solution for a diverse array of industrial and commercial applications.

Engineered to deliver outstanding performance and longevity, our PTFE lined hose boasts a multitude of advantages, establishing itself as the preferred choice for professionals across various industries.

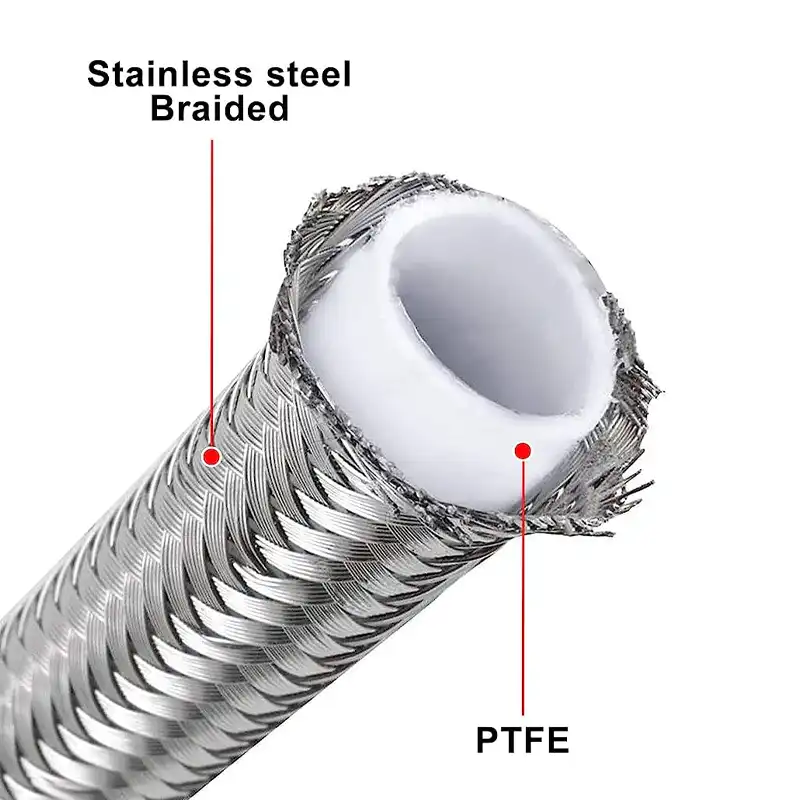

Inner Tube: Seamless black conductive convoluted PTFE

Cover: Braided stainless steel

Temperature: -20°F to 350°F

Our PTFE lined fuel hose assemblies come in two options: convoluted or smooth inner linings. The convoluted PTFE lined hose assemblies provide outstanding flexibility and resistance against kinks. They offer excellent maneuverability, making them suitable for applications where flexibility is crucial. On the other hand, our smooth bore PTFE lined hose assemblies are designed to provide a high flow rate, ensuring efficient fluid transfer. These assemblies are also easy to clean, saving you time and effort.

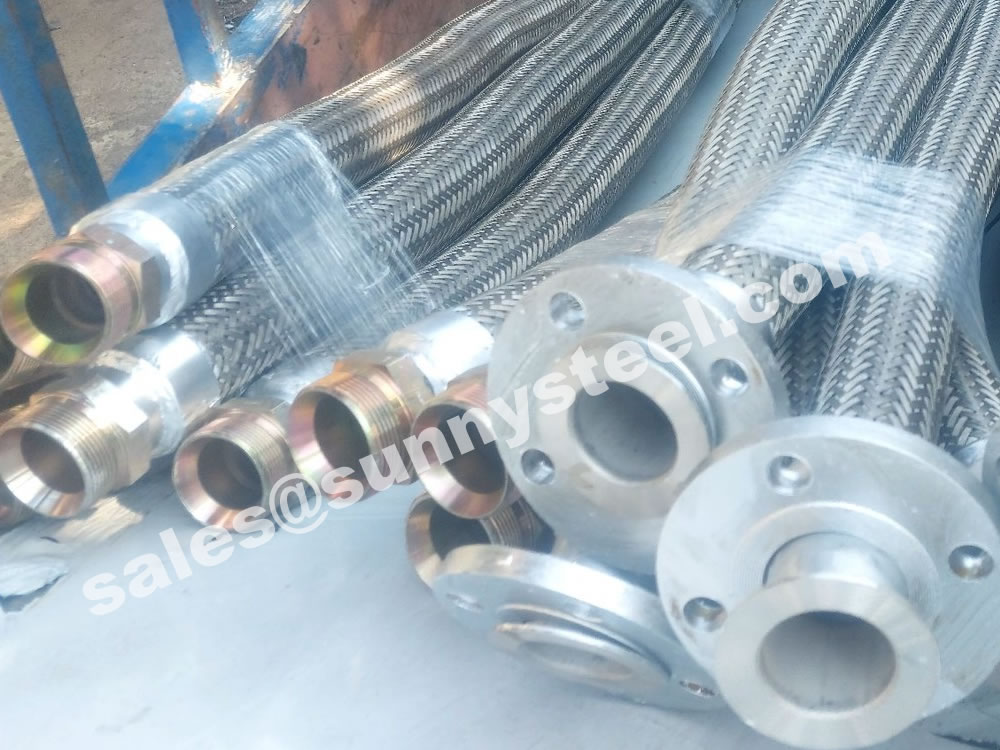

For added strength and durability, our PTFE lined hose assemblies feature a stainless steel over braiding as the most common option. However, we also offer polypropylene over braiding, as well as a range of outer covers, to suit different requirements. This allows you to choose the optimal combination for your specific application.

We understand that coupling options are vital, and that’s why we offer a wide range of coupling choices to ensure compatibility with your existing equipment. We can supply tafted ends, where the PTFE lining is flared over the sealing face of the hose. This feature provides additional protection against aggressive chemicals, giving you peace of mind when handling challenging substances.

Are you in need of a corrosion-resistant and flexible solution? Our PTFE lined flexible hoses are the perfect choice for you. These hoses are constructed with high-quality PTFE lining, providing excellent corrosion resistance and flexibility. Whether in chemical plants, industrial equipment, or other applications, our PTFE lined hoses can meet your needs. Let's explore the features, benefits, and applications of our product.

It's important to consult with a reputable manufacturer or supplier to ensure that the stainless steel metal hose chosen meets the specific requirements of the application.

PTFE lined hoses are used in a variety of demanding applications where chemical inertness, purity, and resistance to corrosion are important. They are commonly used in industries such as chemical processing, pharmaceuticals, food and beverage, and industrial applications. TFE hoses are highly resistant to most chemicals and they do not often release fumes, which is important for any kind of enclosed space. This chemical resistance also means that PTFE hoses will break down a lot more slowly than rubber hoses will.

Stainless steel flexible metal hoses are ready for packing and delivery.

Pipe expansion joints are necessary in systems that convey high temperature commodities such as steam or exhaust gases, or to absorb movement and vibration.

An expansion joint is a useful component in an infinite number of applications.

A bellows is made up of a series of one or more convolutions, with the shape of the convolution designed to withstand the internal pressures of the pipe, but flexible enough to accept the axial, lateral, and/or angular deflections.

Expansion joints are also designed for other criteria, such as noise absorption, anti-vibration, earthquake movement, and building settlement.

Engineers and pipe designers routinely incorporate expansion joints into their pipe systems, as expansion joints add flexibility in to the design and reduce costs through removing the complexity of fix points, guides and reduces the overall space requirements for the pipe system.

Further, expansion joints are more effective than alternatives such as pipe bends and pipe loops due to their greater ability to conserve space, their economic efficiency and better performance in absorbing larger movements.