ASTM A53 Steel Pipe

ASTM A53 steel pipes are widely used for various industrial applications due to their strength and durability.

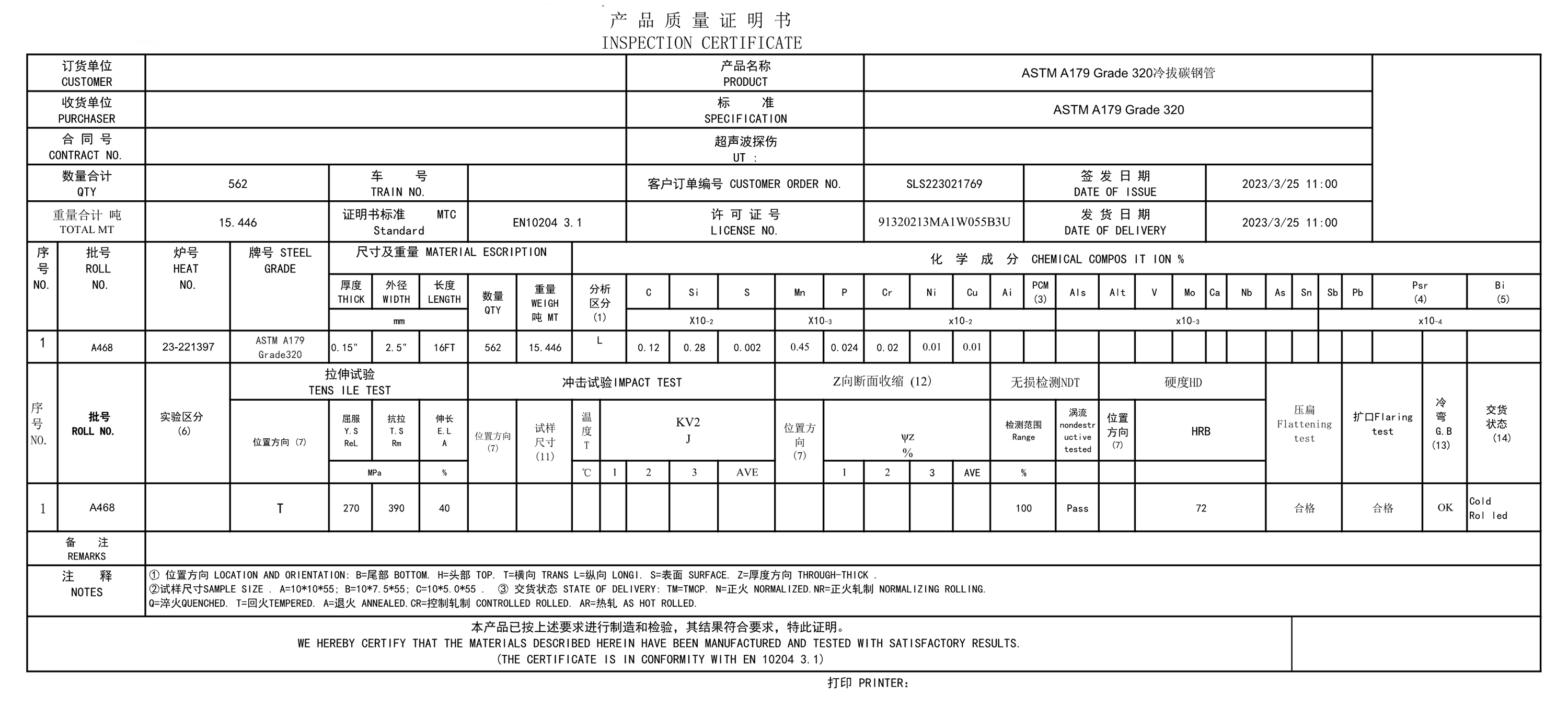

ASTM A179 is an American standard for seamless, cold-drawn, low-carbon steel tubes.

Download PDFASTM A179/A179M is a significant standard in the field of materials and manufacturing.

This standard sets specific requirements for seamless cold-drawn low-carbon steel tubes. It ensures that the tubes produced adhere to strict quality and performance parameters.

The tubes covered by ASTM A179/A179M are designed to offer reliable performance in various applications. Their precise dimensions and mechanical properties make them suitable for heat exchangers, condensers, and other similar systems.

Manufacturers rely on this standard to ensure consistency and quality in the production process. It helps in maintaining uniformity and predictability in the characteristics of the tubes.

End-users benefit from the use of tubes that comply with ASTM A179/A179M as they can expect enhanced durability, efficient heat transfer, and reduced chances of failure.

In conclusion, ASTM A179/A179M plays a crucial role in establishing and maintaining high standards in the production and use of low-carbon steel tubes.

ASTM A179/A179M is a specification covering seamless cold-drawn low-carbon steel tubes for heat-exchanger and condenser applications. These tubes are designed for efficient heat transfer and are widely used in industries such as petrochemical, oil and gas, and power generation.

ASTM A179/A179M tubes are seamless and made from low-carbon steel. The tubes undergo a cold-drawing process to improve dimensional accuracy, surface finish, and mechanical properties, making them suitable for heat exchangers, condensers, and other heat transfer systems. The seamless construction ensures reliability in high-pressure and high-temperature environments.

ASTM A179 tubes are used for heat exchangers, condensers, and other heat transfer equipment. The tubes have a minimum wall thickness and an outside diameter of 1/8 to 3 inches. ASTM A179 tubes are made from carbon steel, which has excellent thermal conductivity and corrosion resistance. The tubes are manufactured using a seamless process, which ensures their uniformity and strength.

ASTM A179/A179M specification covers minimum-wall thickness, seamless cold-drawn low-carbon steel tubes for tubular heat exchangers, condensers, and similar heat transfer apparatus. Tubes shall be made by the seamless process and shall be cold drawn. Heat and product analysis shall be performed wherein steel materials shall conform to required chemical compositions of carbon, manganese, phosphorus, and sulfur. The steel materials shall also undergo hardness test, flattening test, flaring test, flange test, and hydrostatic test.

There are probably hundreds of different methods for packing a abrasion resistant pipe and Elbows, and most of them have merit, but there are two principles that are vital for any method to work prevent rusting and Sea transportation security.

ASTM A179 Tubes shall be made by the seamless process and shall be cold drawn. Heat and product analysis shall be performed wherein steel materials shall conform to required chemical compositions of carbon, manganese, phosphorus, and sulfur. The steel materials shall also undergo hardness test, flattening test, flaring test, flange test, and hydrostatic test.

Because of ASTM A179 grade’s temperature withstanding capabilities, it is applied to steel pipe of tubular heat exchanger, condensers and similar heat transfer equipment. Our ASTM A179 seamless tubes are used in sugar mills & distilleries, pumps and petrochemicals, cement and construction industries and steel plants. Sunny Steel can supply ASTM A179 steel tube from stock or from reputed steel mills. We also offer steel fabrication service where steel plates can go through processings like cutting, welding, bending, machining, pre-coating, pre-lined, beveling, or as you require.

This specification covers minimum-wall thickness, seamless cold-drawn low-carbon steel tubes for tubular heat exchangers, condensers, and similar heat transfer apparatus. Tubes shall be made by the seamless process and shall be cold drawn. Heat and product analysis shall be performed wherein steel materials shall conform to required chemical compositions of carbon, manganese, phosphorus, and sulfur. The steel materials shall also undergo hardness test, flattening test, flaring test, flange test, and hydrostatic test.

ASTM A179 is a standard specification for seamless cold-drawn low-carbon steel tubes used in tubular heat exchangers, condensers, and similar applications.

The ASTM A179 tubes are produced through a cold-drawing process, which helps to improve their dimensional accuracy and surface finish.

ASTM A179/A179M are widely used in industries such as petroleum, chemical, medical, food, light industry, machinery, instrument, include industrial pipeline and mechanical structure parts, etc.

ASTM A179 covers minimum-wall thickness, seamless cold-drawn low-carbon steel tubes for tubular, heat exchanger, condensers, and other heat transfer services. seamless ASTM A 179 steel tube is supplied and produced by cold drawning method. Chemical composition contains carbon, manganese, phosphorus, and sulfur.

ASTMA179/ASME SA179 standard is applicable for steel pipes together with outside diameter of 1/8in-3in. (32 mm to 76.2 mm). Our rolling technology has reached the international advanced spot. JST is able to manufacture cold drawn seamless steel tubes with uniform wall depth. Their tolerance is relatively smaller standard your own.

When seamless carbon steel pipes are during the last cold drawing procedure, they will enter micro oxidization and non-oxidation heat treatment furnace for thermal treatment (Temperature is 1200℉ (650℃) if not more.). This makes the surface of cold drawn seamless steel tubes match the no oxide scale standards, and guarantees smooth surface and stable performance.

JST adopts professional hardness testing equipment to find out the hardness of seamless carbon steel pipes. The Rockwell hardness value not able to exceed 72 HRB.

Top rated program customers' requirements, we can analyze the cold drawn seamless steel tube advertise its chemical composition meet standards. We choose one from 250 pipes or select one in a furnace to investigate. If the product analysis fails, then choose another two seamless carbon steel pipes. All elements of two steel pipes tend to be in accordance with standards, and then these pipes can be delivered.

Note:

| OD(mm) | Wall Thickness Unit(mm) | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2 | 2.5 | 3 | 3.5 | 4 | 4.5 | 5 | 6 | 6.5 - 7 | 7.5 - 8 | 8.5 - 9 | 9.5 - 10 | 11 | 12 | |

| Φ25-Φ28 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ32 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ34-Φ36 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ38 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ40 | ● | ● | ● | ● | ● | |||||||||

| Φ42 | ● | ● | ● | ● | ● | |||||||||

| Φ45 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ48-Φ60 | ● | ● | ● | ● | ● | ● | ● | |||||||

| Φ63.5 | ● | ● | ● | ● | ● | ● | ● | |||||||

| Φ68-Φ73 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ76 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ80 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ83 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ89 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ95 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ102 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ108 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ114 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||

| Φ121 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||

| Φ127 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||

| Φ133 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||

| Φ140 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||

| Φ146 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||

| Φ152 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||

| Φ159 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||

| Φ168 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||

| C | Si | Mn | P | S | Mo | Cr | V |

|---|---|---|---|---|---|---|---|

| 0.06-0.18 | / | 0.27-0.63 | ≤0.035 | ≤0.035 | / | / | / |

| Tensile Strength (Mpa) |

Yield Strength (Mpa) |

Elongation (%) |

Hardness (HRB) |

|---|---|---|---|

| ≥325 | ≥180 | ≥35 | ≤72 |

ASTM A450 covers carbon and low alloy steel tube. Steel samples shall be melt processed and shall either be ingot cast or strand cast. Heat and product analyses shall be performed on the steel materials. Steel specimens shall also undergo tensile tests and shall conform to required values of yield strength and elongation. Flattening test, reverse flattening test, flaring test, flange test, hardness test, hydrostatic test, air underwater pressure test, and nondestructive tests shall be performed on the steel materials.

| OD In (mm) | + | - | WT In(mm) | + | - |

|---|---|---|---|---|---|

| <1(25.4) | 0.10 | 0.10 | ≤1.1/2(38.1) | 20% | 0 |

| 11.1/2(25.438.1) | 0.15 | 0.15 | >1.1/2(38.1) | 22% | 0 |

| >1.1/2<2(38.150.8) | 0.20 | 0.20 | |||

| 2<2.1/2(50.863.5) | 0.25 | 0.25 | |||

| 2.1/2<3(63.576.2) | 0.30 | 0.30 | |||

| 34(76.2101.6) | 0.38 | 0.38 | |||

| >47.1/2(101.6190.5) | 0.38 | 0.64 | |||

| >7.1/29(190.5228.6) | 0.38 | 1.14 |