Cast Basalt Tile Lined Pipes

Durable pipes with basalt tile lining for corrosion resistance.

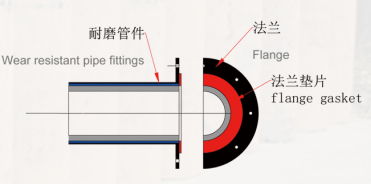

Cast basalt tile lined steel pipe is composed by lined with cast basalt tiles, outside steel pipe and cement mortar filling between the two layers.

Basalt tile lined pipes are commonly used in industries such as power generation, mining, cement, steel, and chemical processing, where the transportation of abrasive materials is required.

Here are some key points about basalt tile lined pipe:

Basalt tile lining provides excellent resistance to abrasion, making it suitable for applications where sliding abrasion is present. It can withstand the wear caused by abrasive materials and extend the lifespan of the pipe.

Cast basalt is a volcanic rock that is melted and cast into shape. It has high hardness, high strength, and excellent resistance to impact and thermal shock.

The use of basalt tile lining in pipes offers several advantages, including superior abrasion resistance, extended pipe life, reduced maintenance costs, and improved operational efficiency.

Basalt tile lined pipes are manufactured by casting basalt into pipe sections or tiles. The cast basalt is then bonded to the inner surface of the pipe using specialized techniques.

A naturally occurring volcanic rock, basalt is one of the toughest natural ceramic materials and can be precast to provide a wide range of products, including tiles, pipe linings and guttering shapes. Up to four times harder than other stone products, basalt is non-porous, highly abrasion and chemical resistant. Melted to 1280°C and cast into steel or sand moulds to produce flat or radial tile shapes to lay as floors, basalt can be retrofitted and installed to protect the bottom sections of existing ovoid or round brick or concrete pipes.

From 50mm up to 3000mm NB basalt is produced as full 360° pipeline systems encased in steel shells for retrofit or new build giving up to 200 years superior life in service. Basalt offers excellent service and high protection from maintenance like jet washing and chemical cleaning to remove blockages caused by waste build up.

Our factory can manufacture and line anything economically transportable by road, covering a diverse range of plant components such as pipelines, cyclones, hoppers, trough chain conveyors, and more.

We are also adept at repairing worn-out components. If necessary, we can perform any required steel metalworking. In such cases, you will receive a refurbished, repaired, and surface-treated plant component equipped with wear protection, ready for installation.

With the most common sizes available in stock, we can promptly deliver various wear protection materials. This allows sufficient time for us to refurbish plant components in our factory during a planned plant shutdown.

| Cast Basalt Pipe DN (mm) |

Standard Steel Pipe OD (mm) |

Cast Basalt Thickness (mm) |

Length (mm) |

|---|---|---|---|

| 80 | 159 | 25 | 4000 |

| 100 | 168 |

17.5 20 |

4000 6000 8000 |

| 125 | 195 | ||

| 150 | 219 | ||

| 175 | 245 |

6000 8000 10000 12000 |

|

| 200 | 273 | ||

| 225 | 300 | ||

| 250 | 325 | ||

| 275 | 345 | ||

| 300 | 377 | ||

| 350 | 426 | ||

| 400 | 478 |

20 25 |

|

| 450 | 529 | ||

| 500 | 600 | 25 | |

| 550 | 650 | ||

| 600 | 720 | 30 | 6000 |

| 650 | 770 | ||

| 700 | 820 | ||

| 750 | 870 | ||

| 800 | 920 |

Other specifications of cast steel pipe lined with basalt can be manufactured according to customer technical requirements. Suitable for large-diameter basalt lining steel pipes with a nominal diameter greater than 800mm. Generally, according to the running status of the pipeline, different cement is used to fix the basalt brick inside the finished steel pipe to complete the basalt lining steel pipe. Its advantages are good wear resistance, wide range of use, basically not limited by the size of the pipeline and low cost of pipeline installation.

Comparison of Ceramic lines with few other materials under standard conditions :

| Material | Thickness(mm) | Approx life ( Months ) |

|---|---|---|

| Mild Steel | 10 | 3-5 |

| Cast Iron | 20 | 6-8 |

| Ni-Hard | 20 | 12-14 |

| Cast Basalt | 30 | 20-25 |

| Ceramic | 10 | 35-40 |

Hard & Compact Smooth & Inner Withstands High-Abrasion & Corrosion In any of the process industries especially Sled and Cement corrosion and abrasion lead to significant downtime of the plant. Further, the useful life or the equipment itself may get impaired because of the high abrasive nature of the materials being used. Thus, ‘wear mechanism’ results in hut down, replacement, etc., which is costly, resulting in loss to tilt: tunic of millions of dollars.

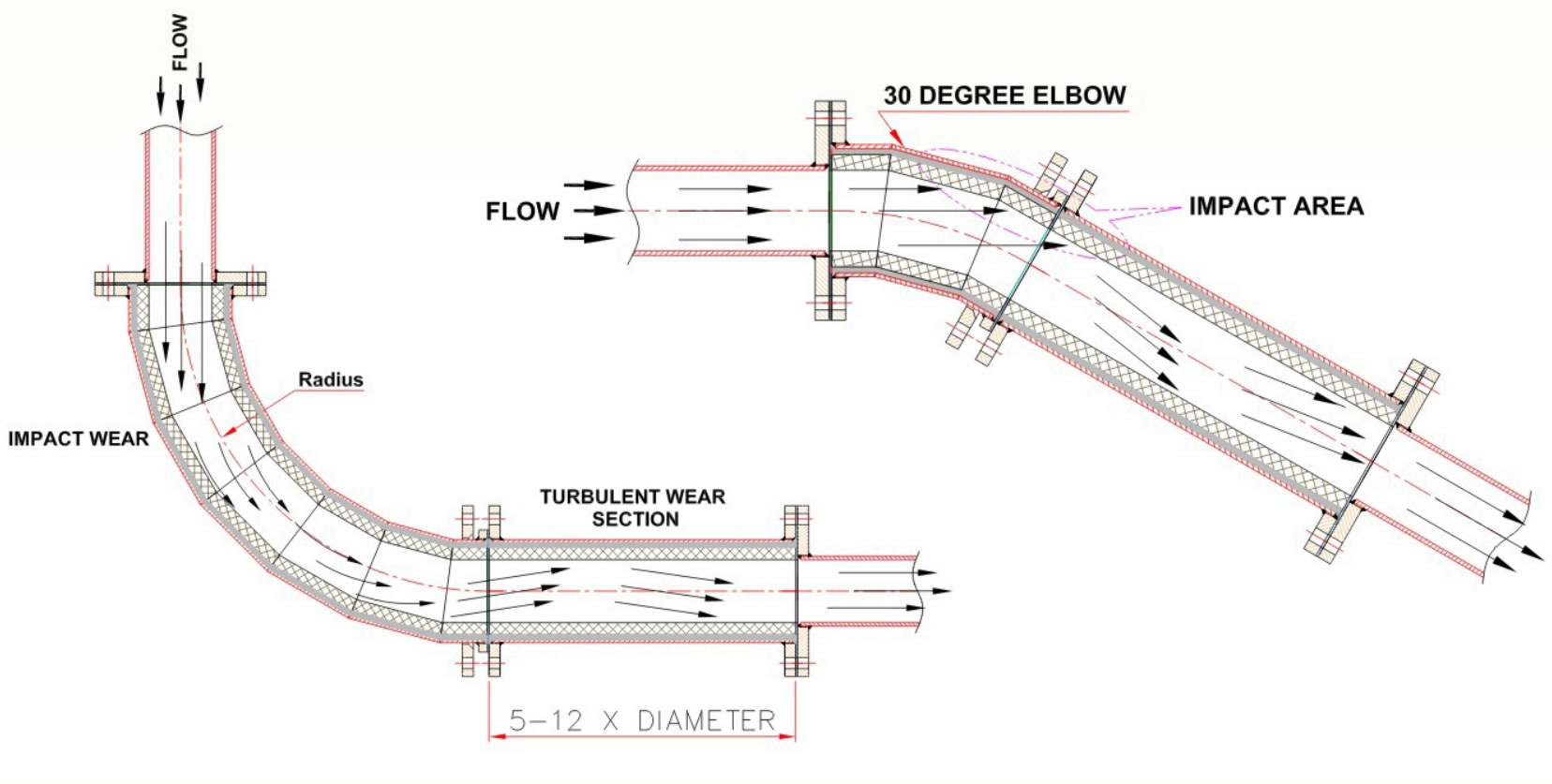

The bend radius should be minimum 3 times of the nominal bore. At discharge end of each bend, cast basalt lined straight pipe of length 5 to 12 times the nominal bore must be used.

Cast blast lined pipe and fittings can connect with flange, quick assembly joints and welding.

Flange connection is one kind of common pipeline installation connections. By two pieces of flanges, pipeline, valve, equipments are connected and it forms a tight piping system. When pipeline pressure is larger, flange connection is priority selection. Flanges have lots of different sizes. Flange size is determined according to pipeline normal diameter and pipeline operation pressure.

The parameters of the outside steel pipe will be decided according to the working pressure of the system. The connection of the pipes and fitting will be of flange connections, easy—flexible joint connection or by welding.

By two pieces of flanges,pipeline,valve,equipments are connected and it forms a tight piping system. When pipeline pressure is larger, flange connection is priority secection. Flanges have lots of differents sizes.

Flange size is determined according to pipeline normal diameter and pipeline operation pressure.

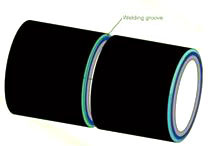

Beveled ends allow for proper alignment and penetration during welding, ensuring a strong and effective joint. This preparation is commonly used in various industries, especially in piping systems where welded connections are prevalent.

It suits short distance pipeline system without maintenance. It is one kind of common installation connections. It requires installation personnel higher welding ability. It also restricts by welding site, distance, welding positions. Welding connections is inconvenient in later maintenance.

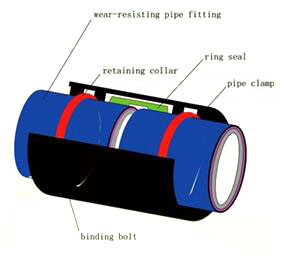

It is one of high efficient and rapid installation connection. I t has the below characteristic: easily install and disassemble, fast installation, temperature adjustable compensation function, saving the necessary expansion in long pipeline. Easy-flexible joint also has angle compensation characteristic. At smaller angle turning points, easy-flexible joint can be instead of bends and adjust angle.

Cast basalt pipe adopt foam packaging, then in accordance with the specifications to put them into wooden cases, sometimes them can be directly loaded into the compartment or container.