API 6D & API 594 Swing Check Valve

Compliant with API 6D and API 594 standards, designed for reliable performance in pipelines.

A check valve is a mechanical device that allows the flow of fluid in one direction while preventing its backflow in the opposite direction.

Check valves are generally installed in pipelines to prevent backflow. A check valve is basically a one-way valve, in which the flow can run freely one way, but if the flow turns, the valve will close to protect the piping, other valves, pumps etc.

Download PDFCheck valves are generally installed in pipelines to prevent backflow. A check valve is basically a one-way valve, in which the flow can run freely one way, but if the flow turns, the valve will close to protect the piping, other valves, pumps etc.

Check valves use a hinged plug that allows water to pass through the pipeline but blocks it from coming back. Backflow preventers, on the other hand, apply an increased amount of pressure on a pipe to ensure the water can only flow one way.

Most common types of Check valves are swing, lift (piston and ball), butterfly, stop and tilting-disk.

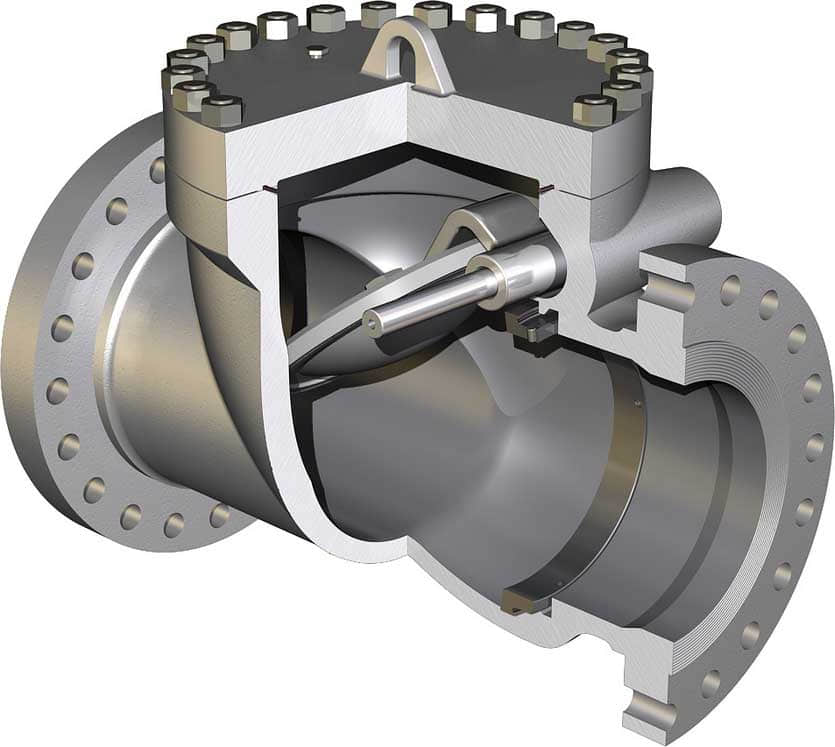

A basic swing Check valve consists of a valve body, a bonnet, and a disk that is connected to a hinge. The disk swings away from the valve-seat to allow flow in the forward direction, and returns to valve-seat when upstream flow is stopped, to prevent backflow.

The disc in a swing type Check valve is unguided as it fully opens or closes. There are many disk and seat designs available, in order to meet the requirements of different applications. The valve allows full, unobstructed flow and automatically closes as pressure decreases. These valves are fully closed when flow reaches zero, in order to prevent backflow. Turbulence and pressure drop in the valve are very low.

The seat design of a lift-Check valve is similar to a Globe valve. The disc is usually in the form of a piston or a ball.

Lift Check valves are particularly suitable for high-pressure service where velocity of flow is high. In lift Check valves, the disc is precisely guided and fits perfectly into the dashpot. Lift Check valves are suitable for installation in horizontal or vertical pipe-lines with upward flow.

Flow to lift Check valves must always enter below the seat. As the flow enters, the piston or ball is raised within guides from the seat by the pressure of the upward flow. When the flow stops or reverses, the piston or ball is forced onto the seat of the valve by both the backflow and gravity.

Flow Direction Control: Check valves permit fluid flow in one direction and automatically close to prevent backflow in the opposite direction.

Mechanical Design: Typically, check valves consist of a hinged or spring-loaded flap, disc, or piston that opens with forward flow and closes with backflow, creating a unidirectional flow path.

Various Types: Check valves come in different designs, including swing check valves, lift check valves, ball check valves, and diaphragm check valves, each suited for specific applications and conditions.

Versatility: Check valves find applications in various industries, such as water and wastewater systems, oil and gas pipelines, HVAC systems, and more.

Preventing Water Hammer: Check valves help prevent water hammer, a sudden pressure surge that can occur when fluid flow is suddenly halted.

Low Maintenance: Due to their simple design, check valves are generally low maintenance, providing reliable and efficient operation over extended periods.

Sizes and Materials: Available in a range of sizes and materials, check valves can be customized to suit specific system requirements, including different pressures and temperatures.

It’s no secret that backflow is one of the most prevalent threats to the purity of our local water supply. Not only can contamination happen everywhere, but it can happen at any time if your plumbing system isn’t set up to prevent it. As such, business professionals, school administrators, and homeowners are all setting out to stop this occurrence and protect the quality of their drinking water. However, this process often comes with confusion regarding what equipment they should use for the job. This article covers the difference between backflow preventers and check valves.

Though backflow preventers and check valves have the same overall function, they both work slightly differently. Check valves use a hinged plug that allows water to pass through the pipeline but blocks it from coming back. Backflow preventers, on the other hand, apply an increased amount of pressure on a pipe to ensure the water can only flow one way.

Backflow systems are generally more effective at keeping wastewater flowing in the correct manner because they’re highly pressurized. They also have several additional fail-safes that further protect our more sensitive drinking water sources. Check valves have a decent amount of reliability. However, they can fail under the right conditions and contaminate certain supplies with sewer water.

We offer valves of various materials which can meet your needs on diverse occasions. Come get your valves right now!

Our Valves materials can be the following grade, another grade is also available on request.

TITANIUM ALLOY:

Titanium Gr.2, Gr.3, Gr.5, Gr.6, Gr.7, Gr.12

NICKEL ALLOY:

Inconel 600, 625; Hastelloy B, B-2, B3, C276, C-22, C-4, G; Incoloy 800, 800H, 825; Monel 400, K500; Nickel 200, 201

ZIRCONIUM ALLOY:

Zirconium 702, 705

BRONZE:

C95800, C95500, C95400, C63200

SUPER STAINLESS STEEL:

904L, 254SMO, AL-6XN, ALLOY20

DUPLEX&SUPER DUPLEX:

S31803, S32750, S32760

STAINLESS STEEL:

SS304, SS304L, SS316, 316L, 316Ti, SS317, 317L, 347SS, SS310

Many kinds of valves are used in the industrial process, and to ensure proper functionality, compatibility, and safety for end-users, EPC, or engineering, every country has particular organizations to make standards.

The major standard organizations include the American National Standards Institute(ANSI), American Petroleum Institute(API), The American Society of Mechanical Engineers(ASME), British(BS), China valve standards(GB, JB, HG), and so on. THINKTANK provides standard resources for all interesting valves friends study.

American National Standards Institute

| ANSI Standard Code | ANSI Standard Name |

|---|---|

| ANSI A126 | Grey iron castings for valves flanges and pipe fittings |

| ANSI A181 | Standard specifications for forged or rolled steel pipe flanged forged fittings and valves and parts for general service |

| ANSI B16.10 | Face to face and end to end dimension of ferrous valves |

| ANSI B16.34 | Steel valves |

| ANSI B127.1 | Constant-level oil valves |

The American Petroleum Institute

| API Standard Code | API Standard Name |

|---|---|

| API SPEC6D | Supplement 1 to API spec 6D (sixteenth edition ) specification for pipeline valves |

| API STD6D | Steel gate plug ball and check valves for pipeline service |

| API STD6D | API Specification for flanged steel gate and plug valves for drilling and production service |

| API SPE14D | API Specification for wellhead surface safety valves for offshore service |

| API 526 | Flanged steel safety relief valves |

| API 527 | Commercial seat tightness of safety relief valves with metal – to metal seats |

| API 528 | API standard for safety relief valve nameplate nomenclature |

| API 529 | Cast – forged Steel plug valves flanged ends |

| API 594 | Wafer-type check valves |

| API 595 | Cast iron gate valves flanged ends |

| API 597 | Steel venturi gate valves flanged or butt welding ends |

| API 598 | Valve inspection and test |

| API 599 | Steel plug valves flanged or butt welding ends |

| API 600 | Flanged and butt – welding – end steel gate and plug valves for refinery use |

| API 602 | Compact design carbon steel gate valves for refinery use |

| API 603 | 150 – pound light – wall corrosion – resistant gate valves for refinery use |

| API 604 | Ductile iron gate valves flanged ends |

| API 607 | Fire-resistant testing of ball valves with soft contact faces |

| API 609 | Butterfly valves to 150 PSIG and 150 F |

| API SPEC 6FA | Specification for fire test for valves |

| API SPEC 6FC | Specification for fire test for valves with automatic backseats |

| API BULL 6RS | Bulletin on referenced standards for committee 6, standardization of valves and wellhead equipment |

| API RP 11V6 | Recommended practice for the design of continuous flow gas lift installations using injection pressure operated valves first edition |

| API RP 11V7 | Recommended practice for repair, testing, and setting gas lift valves |

| API RP 520 PT 1 | Sizing, selection, and installation of pressure-relieving devices in refineries part 1- sizing and selection |

| API RP 574 | Inspection of piping, tubing, valves, and fittings first edition, replaces guide for inspection of refinery equipment Chapter XI |

| API RP 576 | Inspection of pressure-relieving devices first edition |

| API STD 608 | Metal ball valves-flanged, threaded, and welding end |

The American Society of Mechanical Engineers

| ASME Valve Standard Code | ASME Standard Name |

|---|---|

| ASME A105/105M | Standard Specification for Carbon Steel Forgings for piping applications |

| ASME A181/181M | Standard Specification for Carbon Steel Forgings for General purpose piping |

| ASME A182/182M | Standard Specification for forged or rolled alloy-steel pipe flanges, forged fittings and valves and parts for high-temperature service |

| ASME A727/727M | Standard specification for carbon steel forgings for piping components with inherent notch toughness. |

| ASME A961 | Standard Specification for Common Requirements for Steel Flanges, Forged Fittings, Valves, and Parts for Piping Applications |

| ASME B462 | Standard Specification for Forged or Rolled UNS N08020, UNS N08024, UNS N08026, UNS N08367, and UNS R20033 Alloy Pipe Flanges, Forged Fittings, and Valves and Parts for Corrosive High-Temperature Service |

| ASME B834 | Standard Specification for Pressure Consolidated Powder Metallurgy Iron-Nickel- Chromium-Molybdenum (UNS N08367) and Nickel- Chromium Molybdenum Columbium (Nb) (UNS N06625) Alloy Pipe Flanges, Fittings, Valves, and Parts |

| ASME D5500 | Standard Test Method for Vehicle Evaluation of Unleaded Automotive Spark-ignition Engine Fuel for Intake Valve Deposit Formation |

| ASME F885 | Standard Specification for Envelope Dimensions for Bronze Globe Valves NPS 1/4 to 2 El-1996 R(1996) |

| ASME F992 | Standard Specification for Valve Label Plates El-1997 R(1997) |

| ASME F993 | Standard Specification for Valve Locking Devices El-1997 R(1997) |

| ASME F1020 | Standard Specification for Line-Blind Valves for marine Applications El-1996 RI’1996) |

| ASME F1098 | Standard Specification for Envelope Dimensions for Butterfly Valves – NPS 2 to 24 EI-1993 R(1993) |

| ASME F1271 | Standard Specification for Spill Valves for Use in Marine Tank Liquid Overpressure Protection Applications EI-1995 R (1995) |

| ASME F1370 | Standard Specification for Pressure Reducing valves for Water Systems, Shipboard |

| ASME F1508 | Standard Specification for Angle Style, Pressure Relief Valves for Steam, Gas, and Liquid Services |

| ASME F1565 | Standard Specification for Pressure-Reducing Valves for Steam Service |

| ASME F1792 | Standard Specification for Special Requirements for Valves Used in Gaseous Oxygen Service |

| ASME F1793 | Standard Specification for Automatic Shut-Off Valves (Also Known as Excess Flow Valves, EFV) for Air or Nitrogen Service |

| ASME F1794 | Standard Specification for Hand operated, Globe-Style Valves for Gas (Except Oxygen Gas), and Hydraulic Systems |

| ASME F1795 | standard Specification for pressure-reducing Valves for Air or Nitrogen Systems |

| ASME A230 | Standard specification for steel wire oil – tempered carbon valve spring quality |

| ASME A232 | Standard specification for chromium-vanadium alloy steel valve spring quality |

| ASME A350 | Standard specification for forged or rolled carbon and alloy steel flanges forged fittings and valves and parts for low – temperature service |

| ASME A338 | Standard specification for ultrasonic examination of heavy steel forgings |

| ASME A694 | Standard specification for forgings carbon and alloy steel for pipe flanges fittings valves and parts for high-pressure transmission service |

| ASME A404 | Standards specification for forged or rolled alloy – steel pipe flanged forged fittings and valves and parts specially heat-treated for high-temperature service |

| ASME A522 | Forged or rolled 8% and 9% nickel alloy steel flanges fittings valves and parts for low – temperature service |

British – BS – valve standards

| British Standard Code | British Standard Name |

|---|---|

| BS 1212 | Ball valves (Portsmouth type ) excluding floats |

| BS 1123 | Specification for safety valves, gauges, and other safety fittings for air receivers and compressed air installations |

| BS 1414 | Specification for steel wedge gate valves ( flanged and butt-welding ends ) for the petroleum, petrochemical, and allied industries |

| BS 1552 | Control plug cocks for low-pressure gases |

| BS 1570 | Specification for Flanged and Butt – welding ends steel plug valves for the petroleum industry (excluding well – Head and flow – line valves) |

| BS 1735 | Specification for Flanged cast iron outside – screw – and – yoke edge gate valves class 125, size 1.5 into 24 in for the petroleum industry |

| BS 1868 | Specification for steel check valves (flanged and butt-welding ends ) for the petroleum, petrochemical, and allied industries |

| BS 1873 | Specification for Steel globe and globe stop and check valves (flanged and butt-welding ends ) for the petroleum, petrochemical, and allied industries |

| BS 1952 | Specification for copper alloy gate valves for general purposes |

| BS 1953 | Copper alloy check valves for general purposes |

| BS 1968 | Floats for Ball valves ( copper ) |

| BS 2060 | Copper alloy screw-down stop valves for general purposes |

| BS 2080 | Specification for Face to face, center to face end – to -end and center – to – end dimensions of flanged and butt-welding end steel valves for the petroleum, petrochemical, and allied industries |

| BS 2591 PT.1 | British standard glossary for valves and valve parts (for fluids ) part 1. screw-down stop, check, and gate valves |

| BS 2591 PT.2 | British standard glossary for valves and valves parts ( for fluids) part,2 safety valves and relief valves |

| BS 2591PT.3 | British standard glossary for valves and valve parts (for fluids ) part 3, Plug valves and cocks |

| BS 2591PT.4 | British standard glossary for valves and valves (for fluids ) part4, butterfly valves |

| BS 2591PT.5 | British standard glossary for valves and valve parts ( for fluids ) part5, Ball valves |

| BS 2995 | Specification for cast and forged steel wedge gate, globe, check and plug valves screwed and socket – Welding sizes 2 in and smaller for the petroleum industry |

| BS 3464 | Specification for cast iron gate valves for general purposes |

| BS 3808 | Specification for cast and forged steel flanged, screwed and socket – welding Wedge gate valves (compact design ) sizes 2 in and smaller for the petroleum industry |

| BS 3948 | Specification for cast iron parallel slide valves for general purposes |

| BS 3952 | Specification for cast iron butterfly valves for general purposes |

| BS 3961 | Specification for cast iron screw-down stop valves and stop and check valves for general purposes |

| BS 4090 | Cast Iron check valves for general purposes |

| BS 4133 | Flanged steel parallel slide valves for general purposes |

| BS 4312 | Flanged steel screw-down stop valves and stop and check valves for general purposes |

| BS 4460 | Steel Ball valves for the petroleum industry |

| BS 5146 | Specification for inspection and test of steel valves for the petroleum petrochemical and allied industries |

| BS 5150 | Cast iron wedge and double disk gate valves for general purposes |

| BS 5151 | Cast iron gate (parallel slide ) valves for general purposes |

| BS 5152 | Cast iron globe and globe stop and check valves for general purposes |

| BS 5153 | Cast Iron check valves for general purposes |

| BS 5154 | Copper alloy globe stop and check, check and gate valves for general purposes |

| BS 5155 | Cast iron and carbon steel butterfly valves for general purposes |

| BS 5156 | Screw down diaphragm valves for general purposes |

| BS 5157 | Steel gate (parallel slide ) valves for general purposes |

| BS 5159 | Specification for cast iron and carbon steel ball valves for general purposes |

| BS 5160 | Specification for Flanged steel globe valves, globe stop, check valves and lift type check valves for general purposes |

| BS 5351 | Steel ball valves for the petroleum petrochemicals and allied industries |

| BS 5417 | Test of general-purpose industrial valves |

| BS 5418 | Marking of general-purpose industrial valves |

| China Standard Code | China Standard Name | Adopting Standard |

|---|---|---|

| GB12220 | General valve – marking | ISO 5209 |

| GB12221 | Flanged ends metal valve – face-to-face dimensions | ISO 5752 |

| GB12222 | Multi-turn valve – the connection of the driving device | ISO 5210/1 – 3 |

| GB12223 | Part-turn valve – the connection of the driving device | ISO 5211/1 – 3 |

| GB12224 | Steel valve – general requirements | ANSI B16.34 |

| GB12225 | General valve – copper alloy casting ware technology requirements | ASTM B584 |

| GB12226 | General valve – gray casting iron technology requirements | ISO 185,BS 1452 |

| GB12228 | General valve – carbon forging steel technology requirements | ASTM A 105,A181 |

| GB12229 | General valve – carbon casting steel technology requirements | ASTM A703 |

| GB12230 | General valve – Ao casting steel technology requirements | ASTM A351 |

| GB12232 | General valve – flanged ends iron gate valve | ISO5996-1982, API 595 |

| GB12233 | General valve – iron gate valve and lift check valve | BS5152,5153 |

| GB12234 | General valve – flanged and butt-welding ends copper gate valve | API 600 |

| GB12237 | General valve – flanged and butt-welding ends steel ball valve | ISO7121, API 607 |

| GB12238 | General valve – flanged and wafer ends butterfly valve | BS5155 |

| GB12239 | General valve – diaphragm valve | BS5156,NFE29 |

| GB12240 | General valve – iron plug valve | API 593 |

| GB12241 | Safety valve – general requirements | ISO 4126 |

| GB12242 | Safety valve – characteristic testing solution | ANSI/ASME PTC25.3 |

| GB12243 | Direct spring-loaded safety valve | JIS B 8210 |

| GB12244 | Pressure reducing valve – general requirements | JIS B 8372, B8410 |

| GB12245 | Pressure reducing valve – characteristic testing solution | JIS B 8372, B8410 |

| GB12246 | Pilot operated pressure reducing valve | JIS B 8372, DSS405 |

| GB12247 | Steam trap valve – classification | ISO 6704 |

| GB12248 | Steam trap valve – technology terms | ISO 6552 |

| GB12249 | Steam trap valve – marking | ISO 6553 |

| GB12250 | Steam trap valve – face-to-face dimensions | ISO 6554 |

| GB12251 | Steam trap valve – testing solution | ISO 6948,7841,7842 |

| GB/T13927 | General valve – pressure testing | ISO 5208 |

| JB/T6899-93 | Valve fire-proof test | ISO10497 |

| JB/T7927-95 | Valve casting steelware out-form quality requirements | MSS SP55 |

| ZBJ16006-90 | Inspection and testing of valve | API 598 |

| China Standard Code | China Standard Name |

|---|---|

| GB12220 | General valve – marking |

| GB12221 | Flanged ends metal valve – face-to-face dimensions |

| GB12222 | Multi-turn valve – connection of the driving device |

| GB12223 | Part-turn valve – connection of the driving device |

| GB12224 | Steel valve – general requirements |

| GB12225 | General valve – copper alloy casting ware technology requirements |

| GB12226 | General valve – gray casting iron technology requirements |

| GB12227 | General valve – ductile casting iron technology requirements |

| GB12228 | General valve – carbon forging steel technology requirements |

| GB12229 | General valve – carbon casting steel technology requirements |

| GB12230 | General valve – a casting steel technology requirements |

| GB12232 | General valve – flanged ends iron gate valve |

| GB12233 | General valve – iron gate valve and lift check valve |

| GB12234 | General valve – flanged and butt-welding ends copper gate valve |

| GB12235 | General valve – flanged steel stop and lift check valve |

| GB12236 | General valve – steel swing check valve |

| GB12237 | General valve – flanged and butt-welding ends steel ball valve |

| GB12238 | General valve – flanged and wafer ends butterfly valve |

| GB12239 | General valve – diaphragm valve |

| GB12240 | General valve – iron plug valve |

| GB12241 | Safety valve – general requirements |

| GB12242 | Safety valve – characteristic testing solution |

| GB12243 | Direct spring-loaded safety valve |

| GB12244 | Pressure reducing valve – general requirements |

| GB12245 | Pressure reducing valve – characteristic testing solution |

| GB12246 | Pilot operated pressure reducing valve |

| GB12247 | Steam trap valve – classification |

| GB12248 | Steam trap valve – technology terms |

| GB12249 | Steam trap valve – marking |

| GB12250 | Steam trap valve – face-to-face dimensions |

| GB12251 | Steam trap valve – testing solution |

| GB/T13927 | General valve – pressure testing |

| GB/T13932 | General valve – iron swing check valve |

| GB/T15185 | Iron and copper ball valve |

| GB/T15188.1 | Valve face-to-face dimensions – butt-welding ends valve |

| GB/T15188.2 | Valve face-to-face dimensions – wafer ends valve |

| GB/T15188.3 | Valve face-to-face dimensions – female screw-down valve |

| GB/T15188.4 | Valve face-to-face dimensions – male screw-down valve |

| JB93 | Handle |

| JB94 | Spanner |

| JB106 | Valve – marking and identifying paint |

| JB308 | Valve – type establishing a way |

| JB/T450 | PN16.032.0Mpa forging angle type high-pressure valve, fastener, and technology requirements |

| JB451 | Lever-type safety valve technology requirements |

| JB1308 | Pg(2500kgf/cm2)valve type and base specification |

| JB1309 | Pg(2500kgf/cm2)valve pipe and fastener technology requirements |

| JB/T1691 | Valve key construction element dimension of the stemhead |

| JB1692 | Umbrella type handwheel |

| JB1693 | Plane handwheel |

| JB1694 | Valve stem nut (1) |

| JB1695 | Valve stem nut (2) |

| JB1696 | Valve stem nut (3) |

| JB1698 | Valve stem nut (5) |

| JB1699 | Valve stem nut (4) |

| JB1700.1 | Locking nut (1) |

| JB1700.2 | Locking nut (2) |

| JB1701 | Valve stem nut (6) |

| JB1702.1 | Bearing gland (1) |

| JB1702.2 | Bearing gland (2) |

| JB1703 | Sleeve liner |

| JB1706 | Pressing sleeve nut |

| JB1708 | Gland |

| JB1709 | T type bolt |

| JB1712 | Asbestos packing |

| JB1713 | Packing seat(1) |

| JB1716 | Packing seat(2) |

| JB/T1717 | Valve construction key element back seat ring dimensions |

| JB1718 | Spacer (1) |

| JB1719 | Spacer (2) |

| JB1720 | Spacer (3) |

| JB1721 | Spacer (4) |

| JB1726 | Valve disc seat |

| JB1727 | Folio circle |

| JB1728 | Stop collar |

| JB/T1732 | Valve construction key element taper sealing face dimensions |

| JB/T1733 | Valve construction key element valve body copper sealing face dimensions |

| JB/T1734 | Valve construction key element wedge disc and valve disc copper sealing face dimensions |

| JB1735 | Foot valve disc sealing ring |

| JB1736 | Swing check valve disc sealing ring |

| JB1737 | Swing check valve disc sealing ring pressing board |

| JB/T1738 | Valve construction key element dimensions of wedge gate valve body slideway and slideway groove |

| JB/T1739 | Valve construction key element dimensions of wedge gate valve body sealing plane clearance and wedge angle |

| JB/T1740 | Valve construction key element dimensions of wedge disc sealing plane |

| JB1741 | Thimble |

| JB1742 | Adjusting ring |

| JB1747 | Packing ring |

| JB1749 | Ammonia valve disc |

| JB/T1750 | Valve construction key element ammonia valve body sealing plane dimensions |

| JB/T1751-92 | Valve construction key element socket welding and fitting pipe head dimension |

| JB/T1752-92 | Valve construction key element male screw ends head dimensions |

| JB1753-91 | Joint ring |

| JB1754-91 | Joint |

| JB1755-91 | Joint nut |

| JB/T1756-92 | Valve construction key element dimensions of bayonet joint ends |

| JB1757-91 | Bayonet |

| JB1758-91 | Bayonet nut |

| JB1759-91 | Bearing ring |

| JB1760- 91 | Six-angle bolt |

| JB1761-91 | Bolt ring |

| JB/T1762-92 | Valve construction key element spanner dimensions |

| JB2202-77 | Direct spring-loaded safety valve specification |

| JB2203-77 | Direct spring-loaded safety valve face-to-face dimensions |

| JB2205-77 | Reducing valve face-to-face dimensions |

| JB2206-77 | Reducing valve technology requirements |

| JB2311-78 | Ball valve technology requirements |

| JB2765-81 | Valve technology terms |

| JB2766-92 | PN16.0- 32.0Mpa dimensions of forging high-pressure valve |

| JB/T2768-92 | PN16.0- 32.0Mpa Pipe, piping fitting, valve head dimensions |

| JB/T2769-92 | PN16.0- 32.0Mpa screw flange |

| JB/T2770-92 | PN16.0- 32.0Mpa joint nut |

| JB/T2771-92 | PN16.0- 32.0Mpa joint |

| JB/T2772-92 | PN16.0- 32.0Mpa Blind plate |

| JB/T2773-92 | PN16.0- 32.0Mpa double head bolt |

| JB/T2774-92 | PN16.0- 32.0Mpa double-bolt ends and thread hole dimensions |

| JB/T2775-92 | PN16.0- 32.0Mpa nut |

| JB/T2776-92 | PN16.0- 32.0Mpa lens ring |

| JB/T2777-92 | PN16.0- 32.0Mpa Non-hole lens ring |

| JB/T2778-92 | PN16.0- 32.0Mpa temperature marking of pipe and fastener |

| JB3328-83 | Air jar valve and pipe-line valve |

| JB3339-83 | Little type medical air jar frame type valve connection dimensions |

| JB5206.1-91 | Packing gland (1) |

| JB5206.2-91 | Packing gland (2) |

| JB5206.3-91 | Packing gland (3) |

| JB5207-91 | Packing pressing plate |

| JB5208-91 | Separating circle |

| JB5209-91 | Plastics packing |

| JB5210-91 | Back sealing ring |

| JB5211-91 | Gate valve seat ring |

| JB/T5296-91 | General valve testing way of flow rate coefficient and flow resistant coefficient |

| JB/T5298-91 | Steel plate gate valve for pipeline using |

| JB/T5299-91 | General valve Hydraulic actuator butterfly type check valve |

| JB/T5300-91 | General valve material |

| JB/T6438-92 | Valve sealing face plasma arc welding – technology requirements |

| JB/T6439-92 | Valve pressing casting steelware – magnetism powder flaw detector inspection |

| JB/T6440-92 | Valve pressing casting steelware – rax irradiating inspection |

| JB/T6441-92 | The safety valve for compressor purpose |

| JB/T6495-92 | Valve construction key element Gate valve (or disc) T type groove dimensions |

| JB/T6496-92 | Valve construction key element packing dimensions |

| JB/T6497-92 | Valve construction key element stem head dimensions |

| JB/T6498-92 | Valve construction key element disc and stem connection groove dimensions |

| JB/T6899-93 | Valve fire-proof test |

| JB/T6900-93 | Draught valve |

| JB/T6901-93 | Seal type glasses valve |

| JB/T6902-93 | Valve casting steelware hydraulic penetrating inspection way |

| JB/T6903-93 | Valve forging steelware superwave inspection way |

| JB/T6904-93 | Inspection and testing of air jar valve |

| JB/T7248-94 | Technology terms of low temperature casting steel for valve purpose |

| JB/T7744-95 | Valve sealing face alloy powder for plasma arc welding |

| JB/T7745-95 | Pipeline ball valve |

| JB/T7746-95 | Diameter-shrinking forging steel valve |

| JB/T7747-95 | Needle type stop valve |

| JB/T7748-95 | Valve clearance degree and inspection way |

| JB/T7749-95 | Technology terms of sub-zero valve |

| JB/T7927-95 | Valve casting steelware out-form quality requirements |

| JB/T7928-95 | General valve offer requirements |

| JB/Z243-85 | Gate valve static pressure length of life test rules |

| JB/Z244-85 | Stop valve static pressure length of life test rules |

| JB/Z245-85 | Plug valve static pressure length of life test rules |

| JB/Z246-85 | Ball valve static pressure length of life test rules |

| JB/Z247-85 | Valve – electrically device length of life test rules |

| JB/Z248-85 | Butterfly valve static pressure length of life test rules |

| ZBJ16002-87 | Valve electrically driving apparatus technology terms |

| ZBJ16004-88 | Reducing valve type and basing coefficient |

| ZBJ16006-90 | Inspection and testing of valve |

| ZBJ16007-90 | Steam trap valve technology terms |

| ZBJ16008-90 | Hydraulic petroleum gas device urgent shutdown valve – technology terms |

| ZBJ16009-90 | Valve pneumatic actuator technology terms |

| JB/T8473-96 | Instrument valve series |

| JB/T8528-97 | General valve electric actuator – technology terms |

| JB/T8527-97 | Metal sealing butterfly valve |

| JB/T8529-97 | Explosion-proof type valve electric actuator – technology terms |

| JB/T8530-97 | Valve electric actuator – type establishing a way |

| JB/T8531-97 | Valve manual actuator – technology terms |

| JB/T8670-97 | YBDF2 series explosion-proof three-phase asynchronous generator for valve electric actuator purpose – technology terms |

The Fluid Control Institute (FCI) provides standards and other materials to assist purchasers and users in understanding and using fluid control and conditioning equipment such as control valves, solenoid valves, and regulators.

| FCI 68-2 | Procedure in rating flow and pressure characteristic of solenoid valve for liquid service. |

|---|---|

| FCI 70-1 | Standard terminology and definition for filled thermal systems for remote sensing temperature regulators |

| FCI 75-1 | Test conditions and procedures for measuring electrical characteristics of solenoid valves |

| FCI 82-1 | Recommended methods for testing and classifying the water hammer characteristics of electrically operated valves. |

| FCI 84-1 | Metric definition of the valve flow coefficient CV |

| FCI 91-1 | The standard for qualification of control valve stem seals |

Valves are found in virtually every industrial process, including water and sewage processing, mining, power generation, processing of oil, gas and petroleum, food manufacturing, chemical and plastic manufacturing and many other fields.

A valve can be described as a mechanism that controls the passage of liquids through a pipe. Research states that valves being manufactured in China are amongst the top valve competitors in the valve industry.

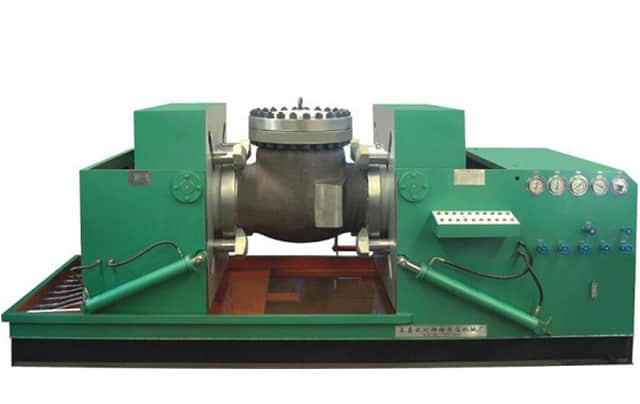

Radiography Inspection guarantees no failures inside of the castings or forgings. Ultrasonic inspection acts an alternative of inspection. Dye penetrant testing and magnetic particle testing can examine surface failures on castings and forgings.

-196 ℃ Cryogenic Treatment System is a basic treatment for LNG usage valves or similiar applications.

Leak testing is a procedure that inspectors use to determine whether an object or system is functioning within a specific leak limit.

All our materials are strictly made under supervision of ladle analysis instrument in the foundries and inspected by high precision spectroanalysis instrument when they arrive in our plant.

All mechanical properties test will act before we use the materials to secure the performance and safety.

Up to 1200 ℃ electric furnance provide an availability of various heat treatment cycles.