DIN 17175 13CrMo44 seamless steel tubes are high-temperature pipes that are designed to withstand high pressure and extreme temperatures.

Download PDF

DIN 17175 13CrMo44 seamless steel tubes are made from alloyed steel and are used in various industries where high temperature and pressure conditions are present.

The 13CrMo44 seamless steel tubes are suitable for applications in steam boilers, gas turbines, and chemical plants, where temperatures can exceed 500°C. The tubes are resistant to corrosion and are ideal for use in highly corrosive environments.

The chemical composition of the 13CrMo44 steel consists of carbon, chromium, molybdenum, and sometimes vanadium. The molybdenum content provides the tubes with increased strength and resistance to high-temperature oxidation.

The tubes are available in various dimensions and can be customized as per customer requirements. They are also subjected to rigorous quality checks to ensure that they meet the required specifications, such as tensile strength, yield strength, and elongation.

In conclusion, DIN 17175 13CrMo44 seamless steel tubes are widely used in high-temperature and high-pressure applications due to their excellent mechanical properties, corrosion resistance, and durability.

DIN 17175 13CrMo44 Seamless Steel Tubes can be used to manufacture steam boilers, pipes, pressure vessels and instruments operating at temperatures up to 600 ° C and at high temperatures.

| Steel Grade | Thermal processing ℃ | Normalizing℃ | Tempering | ||

| Grade | Material number | Quenching temperature ℃ | Tempering temperature ℃ | ||

| 13CrMo44 | 1.7335 | 1100 to 850°C | - | 910-940 | 660-730 |

| Grade | Chemical composition | |||||

| C | Si | Mn | P、S | Cr | Mo | |

| 13CrMo44 | 0.10-0.18 | 0.10-0.35 | 0.40-0.70 | ≤0.030 | 0.70-1.10 | 0.45-0.65 |

| Standard | Grade | Tensile Strength(MPa) | Yield Strength(MPa) | Elongation(%) |

| DIN 17175 | 13CrMo44 | 440-590 | ≥290 | ≥20 |

| Project | Standard | Size range | Tolerance | |||

| Outer diameter | DIN17175 | Hot rolled steel pipe | OD ≤ 100mm | ± 0.75%( Min ± 0.5mm ) | ||

| OD> 100~ 320mm | ± 0.9% | |||||

| Cold drawn steel pipe OD ≤ 120mm | ± 0.6%( Min ± 0.25mm ) | |||||

| Wall thickness | DIN17175 | OD ≤ 130mm | WT ≤ 2Sn | +15%~-10% | ||

| WT > 2Sn~4Sn | +12.5%~-10% | |||||

| WT > 4Sn | ± 9% | |||||

| 130 < OD ≤ 320mm | WT ≤ 0.05OD | +17.5%~-12.5% | ||||

| 0.05OD < WT ≤ 0.11OD | ± 12.5% | |||||

| WT > 0.11OD | ± 10% | |||||

The tube should meet the requirements of the ring test. For the expansion rate (diameter change) of the ring-shaped flaring experiment, no impermissible defects (such as cracks, crepe, folding, and delamination) shall occur during the test.

The tube must have a manufacturing method that achieves a relatively smooth inner and outer surface, so that it is possible to use either a hot rolling method or a cold rolling method. Tubes should not have unacceptable cracks, creases and folds. As long as the wall thickness of the steel pipe does not exceed the allowable dimensional deviation, and does not affect the performance of the steel pipe, it is permissible to create some uneven and shallow longitudinal scratches during the manufacturing process. Mechanical machining (such as buffing) can be used to remove the slight subsidence of the surface, but not to reduce the minimum allowable wall thickness.

Reference data for heat treatment temperature

Hot working is possible from 1100 to 80 ° °C, and the temperature can be reduced to 750 °C during processing.

In the matching-correction work of the local department, attention should be paid to the effective specification of hot work; there should be a supervisory temperature system. In the higher temperature range, ie 1100 to 900 °C, it is suitable for forging and pier thickening, about 85 °C, and the temperature can be lowered to above 75 °C during the processing.

For example, before the last process, or during the same hot working process, if the heating temperature of the workpiece is above the normalizing temperature but not more than 1000 ° C, and the deformation process is above 75 ° C, or ———— In the last process, the degree of deformation does not exceed 5% - at the end of 7 00 °C, then the normalizing of the St35.8, St45.8, 17Mn4, 19Mn5, and 15Mo3 steels is superfluous. The 13CrMo44 and 10CrMo910 only need to be tempered.

For multiple times and/or long time heat treatments at temperatures around 1000 to 1000 °C, the workpiece should be cooled to around 350 °C before the last deformation process. If the normalizing or quenching and tempering treatment is more than enough, then the temperature at which the steel is hot-worked should not exceed 1 000 °C.

Conversely, if the molding end temperature is above 10 °C, then the St35.8, St45.8, 17Mn4, 19Mn5, and 15Mo3 steels must be normalized, while the 13CrMo44 and 10CrMo910 should be tempered.

14MoV63 and X20CrMoV121 steels should be reconditioned after hot work.

Pipes made of steel according to this standard may be cold-worked, such as pipe bending, flaring, drawing and pipe cutting; for X20CrMoV121 and 14CrV63 steels, the high yield point and tensile strength shall be noted. After bending, expanding, and cold drawing with normal deformation, there is no need to supplement the heat treatment.

With years of expertise, we provide a diverse array of steel tube processing options. From sawing and machining tube blanks to intricate bending and upsetting operations, we actively assist you throughout your projects.

Our capabilities extend to eccentricity reduction and concentricity enhancement through turning and grinding. We excel in creating complex geometries using processes like rotary swaging and axial forming. Additionally, we offer property modifications via partial heat treatment, ensuring tailored solutions for your specific needs.

Alloy steel pipes are ideally suitable for chemical, petrochemicals, and other energy-related applications.

The alloy steel pipe adopts high quality carbon steel, alloy structural steel and stainless & heat resisting steel as raw material through hot rolling or cold drawn to be made.

Alloy steel can be used in process area where carbon steel has limitation such as

As an important element of steel products, alloy steel pipe can be divided into seamless steel pipe and welded steel pipe according to the manufacturing technique and tube billet shape.

Here you can see the common alloy steel grade that you will come across.

Why the application of alloy steel pipe is wider than others

There are many kinds of materials used for transport in industrial production. Specifically we will have more choices and it is not limited to the use of alloy steel pipe. But even in the face of more choices, many people tend to choose alloy steel pipe. People make their own choices will have their own reasons. This means the alloy steel pipe application has its own advantages. Compared with transmission lines made of other materials, after it meets the basic application requirements, its quantity is lighter. Then in the practical application of alloy steel pipe, it will have more advantages because of this. Besides its physical characteristic advantage, it also has economic advantages. The wide application of alloy steel pipe is with kinds of reasons. So in practical usage, we can exploit the advantages to the full, in this way can we get more profits in these applications of alloy steel pipe.

The transportation of kinds of gases or liquids in production needs to rely on alloy steel pipe. This shows that the actual role of alloy steel pipe application is important. High temperature resistant and low temperature resistant is the tolerance of temperature. In the practical application of alloy steel pipe, there will be many materials need to be transported. However their temperatures are not the same. So this can be the basic requirement to alloy steel pipe. It needs more corrosion resistance. Corrosion resistant material is the best material during transporting, because it is corrosion resistant. So it can be used in more occasions. And it is definitely very convenient for users.

Can be 100% recycled, environmentally friendly, energy-saving, resource conservation, national strategy, national policy to encourage the expansion of the field of application of high-pressure alloy pipe. Of alloy steel pipe total consumption accounted steel in the proportion is only half of the developed countries, to expand the field of use of the alloy steel pipe to provide a wider space for the development of the industry. The future needs of the average annual growth of China’s high-pressure alloy steel pipe long products up to 10-12%.

Alloy Steel pipe contains substantial quantities of elements other than carbon such as nickel, chromium, silicon, manganese, tungsten, molybdenum, vanadium and limited amounts of other commonly accepted elements such as manganese, sulfur, silicon, and phosphorous.

Our team of experienced sales specialists proudly partners with gas and chemical processors, power generation plants, oil refineries, and related industries to offer piping components and value-added services.

The biggest advantages of alloy steel pipe can be 100% recycled, environmentally friendly, energy-saving, resource conservation, national strategy, national policy to encourage the expansion of the field of application of high-pressure alloy pipe. Of alloy tube total consumption accounted steel in the proportion is only half of the developed countries, to expand the field of use of the alloy tube to provide a wider space for the development of the industry. According to the Chinese Special Steel Association alloy pipe Branch Expert Group, the future needs of the average annual growth of China’s high-pressure alloy pipe long products up to 10-12%.

Steel pipe delivery status(condition): cold / hard (BK), cold / soft (BKW), after cold stress relief annealing (BKS), annealing (GBK), normalized (NBK).

| Term | Symbol | Explanation |

|---|---|---|

| Cold-finished/hard (cold-finished as-drawn) | BK | No heat treatment after the last cold-forming process. The tubes therefore have only low deformability. |

| Cold-finished/soft (lightly cold-worked) | BKW | After the last heat treatment there is a light finishing pass (cold drawing) With proper subsequent processing, the tube can be cold-formed (e.g. bent, expanded) within certain limits. |

| Annealed | GBK | After the final cold-forming process the tubes are annealed in a controlled atmosphere or under vacuum. |

| Normalized | NBK | The tubes are annealed above the upper transformation point in a controlled atmosphere or under vacuum. |

The general cold strip mills, volume should go through continuous annealing (CAPL unit) to eliminate cold hardening and rolling stress, or batch annealing reach the mechanical properties of the corresponding standard specifies. Cold rolled steel surface quality, appearance, dimensional accuracy better than hot-rolled plate, and right-rolled thin product thickness is about 0.18mm, so the majority of users favor.

Cold rolled steel coil substrate products deep processing of high value-added products. Such as electro-galvanized, hot dip galvanized, electro-galvanized fingerprint resistant, painted steel roll damping composite steel, PVC laminating steel plates, etc., so that the excellent quality of these products has a beautiful, high resistance to corrosion, has been widely used.

Cold rolled steel coil finishing after annealing, cut the head, tail, trimming, flattening, smooth, heavy volume, or longitudinal clipboard. Cold-rolled products are widely used in automobile manufacturing, household electrical appliances, instruments, switches, buildings, office furniture and other industries. Steel plate strapping package weight of 3 to 5 tons. Flat sub-volume typically 3 to 10 tons / volume. Coil diameter 6m.

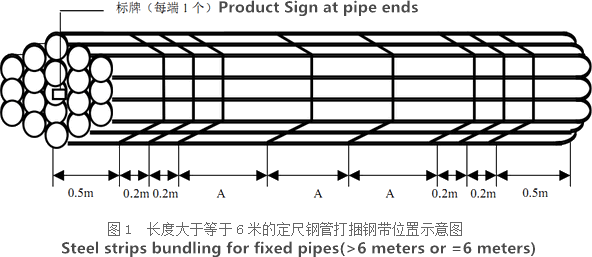

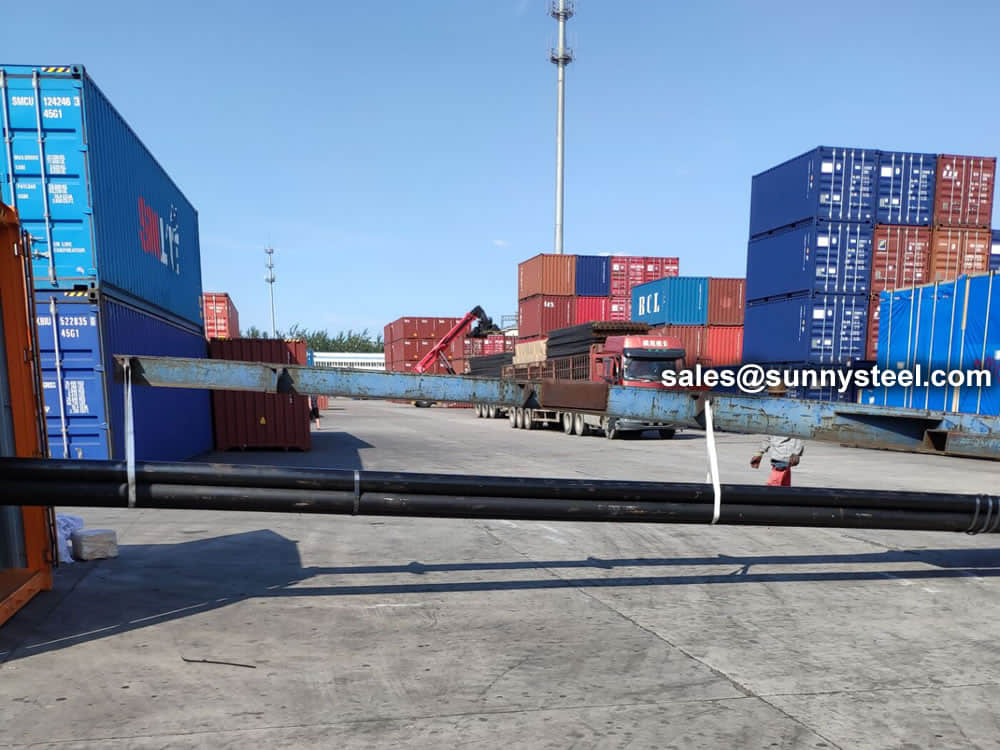

Bare packing/bundle packing/crate packing/wooden protection at the both sides of tubes and suitably protected for sea-worthly delivery or as requested.

There are probably hundreds of different methods for packing a pipe, and most of them have merit, but there are two principles that are vital for any method to work prevent rusting and Sea transportation security.

Our packing can meet any needs of the customers.