A flexible rubber elbow is a type of plumbing fitting used to connect and redirect pipes at a 90-degree angle.

Download PDFIt is designed to provide flexibility and accommodate slight misalignments or movement in the piping system. The rubber material allows for easy installation and provides a secure and leak-free connection.

Economy: Compared with the systems of mechanic stretching and material damping, it has the advantages of little space covering, light weight, easy assembly and disassembly, labor saving and low cost. Its smooth inner wall can reduce flow resistance. It has good water tightness, so there is no need of gasket during the installation. It has wide application, large temperature-resistance scope and long working life. (This product can be used for 20 years if it is used indoors. )

Displacement: Flange is free from pipe decentraction and imbalance. Its good flexibility allows compression, extension, distortion, deflection of vertical displacement, etc. Which can prevent the pipeline from damage of deformation and foundation settlement arising from expansion caused by heat and contraction caused by cold.

Shock and noise absorption: The large damping of rubber sphere can effectively buffer and isolate vibration, control and reduce mechanical vibration, and absorb fluid impact noise. The reasonable installation between vibrating machine and metal pipe can decrease structure-borne noise by 15-25 decibels.

Pressure resistance: The multilayered sphere structure can especially endure internal pressure, withstand strong blasting force and impact, and prevent deformation from external pressure. There are many pressure standards on work piece.

Reducibility: After external force compressed, it can recover to original state when this force is removed.

Wide application: Different rubber material and formula can make product possess different resistance to heat, oil, corrosion, age, abrasion and ozone.

Rubber compensators are widely applied in a variety of industrial pipelines, in power plants, in heating networks (heat transfer stations) and sanitary installations (sewage treatment plants and pumping stations, water treatment stations and machines). Basically, they are mounted near components that produce vibrations (pumps, engines, turbines, compressors etc.). They absorb different movements: axial, lateral and angular that result from thermal expansion of the pipelines or misalignment. They dampen vibration and noise and absorb the energy of pressure variations.

Rubber expansion joints offer flexibility allowing concurrent movements, isolation of vibration, reduction of noise, resistance to abrasion and chemical erosion within fluid systems.

Here are the key benefits of rubber expansion joints:

Rubber joints can absorb greater movements when compared to similar length metal expansion joints. Equipment such as pumps, compressors and piping can move out of alignment due to wear and settling of their supporting structures. Rubber expansion joints can routinely manage the resulting lateral, torsional and angular movements whilst strategically located rubber expansion joints can mitigate thermal expansion and contraction movements. Metal joints typically have a lower lateral movement capability and the allowance for movement offered by rubber expansion joints has positive benefits in extending system life and maintenance intervals.

Reducing vibration is important to prevent unbalanced forces building up to a level where they can damage a fluid system. Rubber pipe and expansion joints dampen these disturbances and provide resistance against shock stress from hydraulic surge and water hammer.

As systems age and wear, imbalances occur which cause unwanted noise. Rubber expansion joints dampen sound transmission with their rubber to steel interface. When compared to full metal joints, thick-walled rubber expansion joints offer a much higher reduction of sound transmission.

Metal joints are typically thin wall elements, having a wall thickness anywhere between 0.15mm to 2mm. Rubber joints are thicker, from 12mm to over 25mm. Metal expansion joints are susceptible to chemical erosion and abrasion whereas rubber joints are resistant to abrasion and erosion.

A wide variety of natural, synthetic, and special purpose elastomers and fabrics are available to create high performance rubber expansion joints to meet challenging operating conditions. Special polymers resist chemicals, oil, sunlight, acid fumes, ozone and external coatings can be added for further protection.

Expansion joints may use PTFE (polytetrafluoroethylene) and FEP (fluoroethylene propylene) liners within the joint body. When fluoroplastics are used in rubber expansion joints this results in better thermal stability, low friction and resistance to corrosive fluids, chemicals, abrasion and erosion.

The ability to flex and absorb gives rubber expansion joints a distinct advantage over metal joints since natural and synthetic elastomers are not subject to fatigue breakdown, loss of ductility or electrolytic reaction. This results in a long-lasting expansion joint.

Rubber expansion joints are light in weight compared to metal expansion joints, making them easy to handle and install. The vulcanized rubber and fabric flanges of elastomeric expansion joints are integrated and therefore do not require additional gaskets which also eliminates the need for ongoing gasket maintenance checking. Additionally, elastomeric expansion joints can equalize the uneven surfaces of the pipe flange to provide a gas tight seal.

Rubber expansion joints appear in all fluid systems. Rubber expansion joints relieve stress from movement, isolate vibration, reduce noise and compensate for misalignment in piping systems. Rubber expansion joints do not replace metal expansion joints in all applications but are recognized as the best choice for many applications involving high vibration and sound dampening.

Here are examples of applications that utilize rubber expansion joints:

Rubber expansion joints and connectors are the ideal choice for many piping situations, and they have several uses.

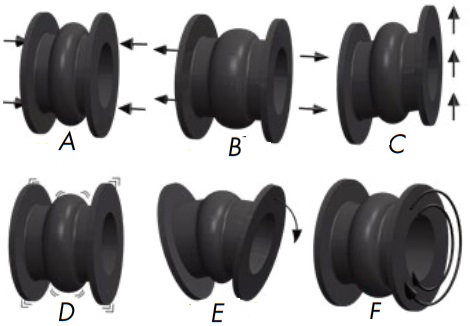

The function of a rubber expansion joint and the absorption of various movements:

A-axial compression, B-axial elongation, C-lateral or transverse movement, D-vibration, E-angular movement, F-torsional movement.

As illustrated in the picture, rubber expansion joints are primarily designed to absorb and compensate for various movements and vibration in a piping systems:

Rubber Expansion Joints for Piping Systems provide time-tested ways to accommodate pressure loads, relieve movement stresses, reduce noise, isolate vibration, compensate for misalignment after plants go on stream, and prolong the life of motive equipment. Rubber expansion joints are available in a variety of styles and are used to convey fluid under vacuum pressure conditions in piping systems. Flanged rubber expansion joints are most common and are available in single – and multi-arch designs. They can be custom-engineered to fit your application requirements. Our rubber expansion joints are particularly beneficial due to their flexible nature, which makes them suitable for many functions, including the absorption of sound, thermal energy and shock. They are specifically designed to reduce the need for maintenance, repair and manual assistance.

Flexible rubber expansion joints offer several benefits in piping systems, contributing to the overall performance, reliability, and longevity of the system. Here are some key advantages:

Changes in temperature and pressure in piping systems connected to pumps lead to thermal expansion and contraction within the pipes. Rubber expansion joints and connectors are the ideal choice for many piping situations, and they have several uses. Rubber expansion joints are most often used as a flexible connector between a vibrating piece of mechanical equipment and the pipeline. They can also be used to absorb pipe movements. Rubber connectors will also provide for a reasonable amount of pipe offset caused by equipment settling.

Available options include PTFE-lined, eccentric reducing, concentric reducing, filled arch, lightweight and off-set configurations. They can be designed to operate up to 200 psi and withstand temperatures up to 500º F. Sizes available from 1/2″ to 144″.

Careful selection of the expansion joint design and material for a given application, as well as properly engineered installation are important factors in determining performance. These factors should be fully evaluated by each person selecting and applying expansion joints for any application.

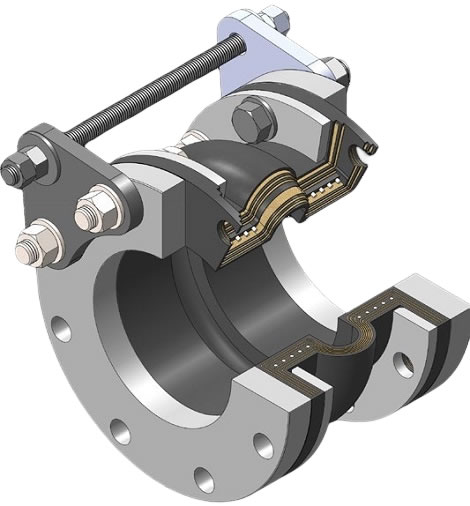

A rubber expansion joint generally consists of inner tube, cover and carcass. The inner tube shall be made of natural rubber, synthetic rubber, or blend of synthetic rubber. It is a seamless protective, leak-proof lining that extends through the bore to the outside edges of the joint. Since the inner tube is in direct contact with the flowing media, it shall be designed to cover service conditions for chemical, petroleum, sewage, gaseous and abrasive materials. The purpose of the tube is to eliminate the possibility of the materials being handled penetrating the carcass and weakening the fabric. The cover is the exterior surface of the joint that is formed from natural or synthetic rubber. The prime function of the cover is to protect the carcass from outside damage caused by atmospheric chemicals, oils, air, sunlight, vapor, etc. The carcass or body of the rubber expansion joint is the flexible and supporting member between the tube and cover. It is the structural framework of the joint and is made from multiple plies woven fabric or tire cord impregnated with synthetic rubber. Steel wires or solid metal rings are often embedded in the carcass to provide additional reinforcement to the body fabric.

3-dimensional model of a spool arch type rubber expansion joint

(1) Integral Rubber Flanges – The end connection flanges of the joint are integrally formed as a part of the elastomeric bellows. It is also called “spool arch type rubber expansion joint”.

(2) Floating Metallic Flanges – The metal flanges shall have a groove to accept the molded bead in the body at each end of the expansion joint bellows.

(3) Spherical Type – Long radius arch, either single sphere or twin sphere, to provide better movement capability and strength.

(4) Control Units – Tie rods or control rods are provided to minimize possible damage to the expansion joint caused by excessive motion of the piping system.

(5) Custom Designs – rectangular flange connection, threaded union connection, tapered reducer type, no-arch U type, hinged type, gimbal type, sleeve type, PTFE lined type.

Carcass

The body of the expansion joint consisting of fabric and / or interior metal reinforcement.

Cover

The natural or synthetic rubber exterior of the joint which protects the carcass from damage.

Fabric Reinforcement

A synthetic or natural fabric between the tube and cover that flexibly supports the expansion joint for movement or pressure.

Metal Reinforcement

Solid rings or wire embedded in the carcass which strengthen the expansion joint to withstand high pressure or vacuum.

Tube

A protective, leak-proof lining tube that extends through the bore to the outside edges of the flanges to eliminate the possibility of the fluids penetrating the carcass and weakening the fabric.

| Single Sphere | Twin Sphere | Union Spherical |

| Spool Arch | Tie Rods | Special Design |

| Flange Drilling | Installation & Maintenance | Testing & Inspection |

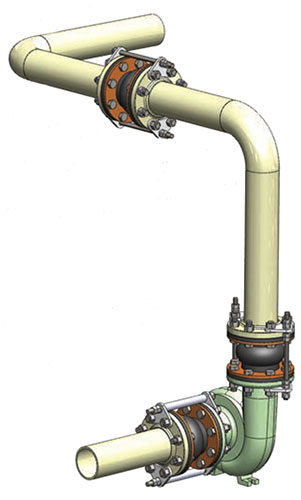

A rubber expansion joint can be used as a flex connector, to absorb noise and vibration from adjacent equipment. In this application, there are usually not anchors in the piping systems and the rubber expansion joint should employ control units to keep the product from expanding under pressure. Control unit nuts should be snug (using 1/4″ thick rubber washers. Alternately, these connectors can be used as a piping expansion joint to absorb thermal pipe growth or temporary pipe movements. Like metal bellows expansion joint systems, in these cases, this rubber product becomes part of the expansion joint system which includes main anchors and pipe alignment guides. Rubber expansion joints can also be used as both flex connectors and expansion joints in the same system. When using rubber connectors as an expansion joint in the piping system, they may or may not be located next to vibrating equipment. Control units can be used as a back-up safety device in the case of an main anchor failure, but nuts and washers should be loosened to allow for the full extension or contraction of the expansion joint.

(Above) Rubber connector used as an expansion joint to take up thermal growth and other pipe movements. There are anchors located on either side of the expansion joint, the joint is located as close to an anchor as possible, and pipe alignment guides are spaced out on the piping to prevent pipe bucking under column loads.

(Above) Rubber connectors used as flex connectors for noise and vibration. There are no piping anchors present and control units are installed on the rubber connectors.

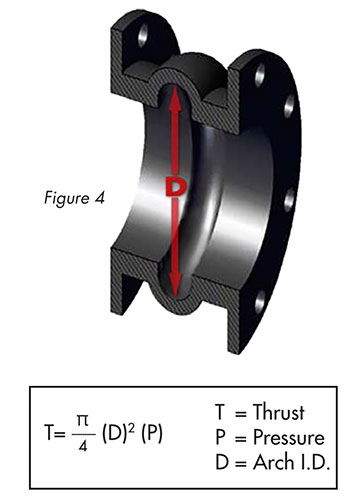

Introducing a flexible product like an expansion joint to your piping system adds an aspect that must be taken into consideration when designing the piping system. Due to pressure thrust forces and spring loads, main anchors must be engineered to handle these increased loads. Unless restrained by control rods, expansion joints expand under pressure, creating pressure thrust forces on the anchors. In addition, the inherent stiffness of the expansion jointy must be overcome in order for these products to absorb thermal pipe growth. For each size and type of expansion joint, we can calculate the effective area of the joint. This figure is multiplied by the system pressure to determine the pressure thrust force. Each product and size also has a spring rate–the force required to compress, expand or offset the product by 1-inch. If we are expecting, for instance, 2-inches of pipe growth and the compression spring rate of our rubber expansion joint is 1000 lbs. per inch, our spring force is calculated to be 2000 lbs. This figure will be added to the pressure thrust force to determine the combined force on system anchors.

There are many choices of styles and configurations of rubber expansion joints. Rubber spheres are mainly used as flex connectors and connected to HVAC equipment to absorb noise and vibration. This type of connector is available in single sphere and double sphere flanged connectors, and double sphere threaded connectors. Flanges are made of plated steel and are able to rotate for easy alignment. Generally, these connectors are made of EPDM or Neoprene rubber. Spool or arch type rubber expansion joints are generally built for more specified applications. They are at least partially hand-built, with wrapped rubber covers, duck and rubber flanges, and a sharp arch configuration to absorb pipe movements. Consider these configuration choices:

Multiple arches

Reducing style

Enlarged flange

Filled arch

Metal liners

Sleeve type

Choosing the appropriate elastomer is crucial when your pipeline conveys liquids other than water. Different elastomers, fluoroelastomers, and fluoroplastics offer varying levels of compatibility with chemicals and abrasive slurries.

Expansion joint liners can be customized to handle a range of substances, including raw sewage, acids, alkaline solutions, hot air, drinking water, abrasive slurries, and more. Some popular elastomer choices include:

Note: Rubber expansion joints are not recommended for use with compressed gases, steam, or extreme temperature liquids.

For shipboard services on commercial vessels, we provide rubber expansion joints that meet U.S. Coast Guard and Federal Regulations standards. Additionally, our mil-spec joints for the U.S. Navy can be built with ANSI flange drilling or Navy drilling.

Carefully consider the maximum pressure your piping system may experience, especially during hydro-testing. Standard rubber expansion joints generally support working pressures from 150 to 225 PSI for most sizes, but higher-pressure options are available upon request. However, keep in mind that higher-pressure expansion joints tend to be heavier and more rigid.

Most rubber expansion joints are reinforced with polyester fabric layers along with steel hoops to enhance vacuum resistance. For even higher pressure ratings, Kevlar reinforcement might be recommended.

Rubber expansion joints are available in sizes ranging from 1-1/2 inches to 36 inches. Single and double rubber spheres, produced using hydraulic molds, come in sizes from 1-1/2 inches to 16 inches, with larger sizes (up to 20 inches) available by special order. Spool-type or arch-type expansion joints can be manufactured in larger diameters, from 1-1/2 inches up to 102 inches.

According to the connection method, there are three kinds of flange type, fixed flange type and thread type; according to the structure, it can be divided into five types: single sphere, double sphere, different diameter body, curved sphere and wind pressure coil. The tubular rubber piece is composed of inner and outer rubber, ply and traveler, and is formed by vulcanization molding and loosening with metal flange or parallel joint. This product can reduce vibration and noise, and can compensate for thermal expansion and contraction caused by temperature changes, and is widely used in various piping systems.

| Nominal diameter(DN) | Length | Axial displacement(mm)

|

Horizontal displacement | Deflexion angle | ||

|---|---|---|---|---|---|---|

| mm | inch | mm | Extension | Compression | mm | (a1+a2)° |

| 32 | 1 1/4 | 95 | 6 | 9 | 9 | 15° |

| 40 | 1 1/2 | 95 | 6 | 10 | 9 | 15° |

| 50 | 2 | 105 | 7 | 10 | 10 | 15° |

| 65 | 2 1/2 | 115 | 7 | 13 | 11 | 15° |

| 80 | 3 | 135 | 8 | 15 | 12 | 15° |

| 100 | 4 | 150 | 10 | 19 | 13 | 15° |

| 125 | 5 | 165 | 12 | 19 | 13 | 15° |

| 150 | 6 | 180 | 12 | 20 | 14 | 15° |

| 200 | 8 | 210 | 16 | 25 | 22 | 15° |

| 250 | 10 | 230 | 16 | 25 | 22 | 15° |

| 300 | 12 | 245 | 16 | 25 | 22 | 15° |

| 350 | 14 | 255 | 16 | 25 | 22 | 15° |

| 400 | 16 | 255 | 16 | 25 | 22 | 15° |

| 450 | 18 | 255 | 16 | 25 | 22 | 15° |

| 500 | 20 | 255 | 16 | 25 | 22 | 15° |

| 600 | 24 | 260 | 16 | 25 | 22 | 15° |

Material selection of rubber expansion joints are very variable and depends on the pressure, temperature, fluid etc. parameters. The common materials are, EPDM, IIR, NBR, PTFE and combined with these materials depends of usage area.

Rubber expansion joints are used in piping installations to compensate for thermal growth, relieve piping stress during operation, and reduce vibration and noise caused by rotating equipment.

The majority of expansion joints can be found off the suction and discharge side of every pump; however, they can also be found near boilers, tanks, cooling towers, heat exchangers and the middle of pipe runs. The average life span of a rubber expansion joint is roughly seven to 10 years.

Installing expansion joints and using a high-quality silicone-based sealant is one important step you can take to ensure that your work will last for years to come. Expansion joints allow space in which concrete can contract and expand without causing cracks.

Rubber expansion joints are vital components in various industries, providing essential flexibility to piping systems. These versatile connectors can accommodate movement, vibration, and thermal expansion, preventing stress and damage to pipelines and equipment. In this comprehensive article, we will delve into the world of rubber expansion joints, exploring their uses, benefits, installation, maintenance, and much more.

Rubber expansion joints are flexible connectors used in piping systems to absorb movement, vibrations, and thermal expansion. Their unique design allows for axial, lateral, and angular movement, making them suitable for a wide range of applications.

Explore the different types of rubber expansion joints available, such as single sphere, twin sphere, and more. Each type has specific features that cater to diverse requirements.

Discover how rubber expansion joints find applications in industries like chemical processing, oil and gas, water treatment, HVAC, and more. Their versatility makes them indispensable in handling various fluid mediums.

Rubber expansion joints offer numerous advantages, including noise reduction, vibration absorption, and stress alleviation, leading to enhanced durability and longevity of piping systems.

Consider critical factors like pressure ratings, temperature range, movement capability, and chemical compatibility when selecting the appropriate rubber expansion joint for a specific application.

Follow detailed step-by-step instructions for the correct installation of rubber expansion joints to ensure optimal performance and prevent potential issues.

Learn about the importance of regular maintenance and inspection to detect potential problems early and extend the service life of rubber expansion joints.

Address common problems that may occur with rubber expansion joints, including leaks, premature wear, and abnormal noises. Find effective solutions to troubleshoot these issues.

Compare rubber expansion joints with other types of expansion joints, such as metal and fabric, and understand their specific advantages and limitations.

Examine the eco-friendliness and recyclability of rubber expansion joints, making them a sustainable choice for various industries.

Explore the various industry standards and certifications that rubber expansion joints must meet to ensure their reliability and safety in critical applications.

Stay up-to-date with the latest technological advancements and innovations in the field of rubber expansion joints, ensuring continuous improvement and enhanced performance.

Gain valuable insights from industry experts and real-life case studies, providing practical applications and success stories of rubber expansion joints.

Q: What are the primary uses of rubber expansion joints?

A: Rubber expansion joints are widely used in piping systems to compensate for movement, absorb vibrations, and reduce stress, ensuring the smooth operation of various industries.

Q: Can rubber expansion joints withstand high temperatures?

A: Yes, rubber expansion joints are designed to withstand a wide temperature range, making them suitable for both high-temperature and low-temperature applications.

Q: How long do rubber expansion joints typically last?

A: The lifespan of rubber expansion joints depends on factors like operating conditions, maintenance, and quality. Well-maintained rubber expansion joints can last for several years.

Q: Are rubber expansion joints resistant to chemicals?

A: Yes, rubber expansion joints are available in various elastomers, each with specific chemical resistance properties, making them suitable for a wide range of fluid mediums.

Q: Can I install rubber expansion joints myself?

A: While some installations can be straightforward, it is recommended to have a professional handle the installation to ensure proper fitting and performance.