Spherical Compensator

Elegant spherical compensators designed for flexibility and pressure compensation.

Rotary compensators, also known as rotary expansion joints, originate from slip type expansion joints.

Download PDFThe rotary sleeve can rotate freely along its longitudinal axis. The packing is stuffed in the space between the rotary sleeve and the body, tightened by the retainer, gland flange and its bolting. Springs may be incorporated into the bolting to ensure a tight loading. The rotary expansion joints can be simply classified as straight type or reducing type according to how its butt welding end transitions to the piping diameter from body diameter. Rotary expansion joints supplied by Shijiazhuang Metalsin have the following advantages: maintenance-free with a 6-year warranty, no pressure thrust, no water hammer, self-pressurized sealing.

The body sleeve, rotary sleeve, retainer, gland flange and the butt welding end connector shall be selected from metallic materials such as carbon steel (ASTM A105, ASTM A106 Gr.B, S235JR, Q235, P235GH), low alloy steel (ASTM A335 P11, P22, P5, 16Mo3, 15CrMo, 12Cr1MoV), stainless steel (SS 304, SS304L, SS 316, SS 316L, SS 317, SS 317L, etc), or nickel alloy (Inconel 625, Monel 400, Hastelloy C-276). The packing material may be flexible graphite, carbon fiber, PTFE, EPDM, NBR, etc. Typical bolting materials include ASTM A193 B7 / ASTM A194 2H, ASTM A193 B8, B8M/ ASTM A194 8, 8M.

Necessary tests for the rotary expansion joints include non-destructive test (NDT), pressure proof test, sealing test, torque test, fatigue test, dimensional examination and visual inspection.

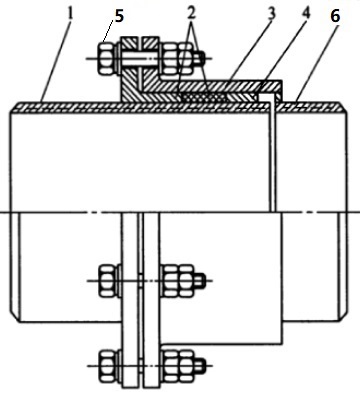

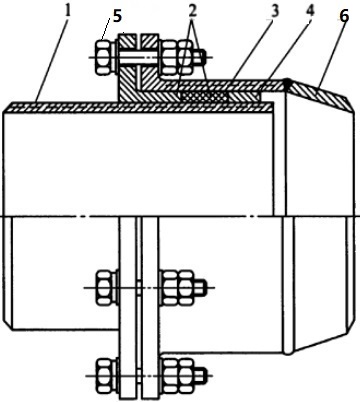

Rotary expansion joints, also known as rotary compensators, originate from slip type expansion joints. Generally, as illustrated in Figures 1-1 & 1-2, they are constructed by a set of components including (1) rotary sleeve, (2) packing & packing gland, (3) body sleeve, (4) anti-blowout retainer, (5) bolting, (6) butt-welding end connection.

The rotary sleeve can rotate freely along its longitudinal axis. The packing is stuffed in the space between the rotary sleeve and the body, tightened by the retainer, gland flange and its bolting. Springs may be incorporated into the bolting to ensure a tight loading. The rotary expansion joints can be simply classified as straight type or reducing type according to how its butt welding end transitions to the piping diameter from body diameter.

Rotary expansion joints are commonly used in various industries, including power generation, oil and gas, chemical processing, and HVAC systems. They are suitable for applications where rotational movement needs to be accommodated while maintaining the integrity of the piping system.

The body sleeve, rotary sleeve, retainer, gland flange and the butt welding end connector shall be selected from metallic materials such as carbon steel (ASTM A105, ASTM A106 Gr.B, S235JR, Q235, P235GH), low alloy steel (ASTM A335 P11, P22, P5, 16Mo3, 15CrMo, 12Cr1MoV), stainless steel (SS 304, SS304L, SS 316, SS 316L, SS 317, SS 317L, etc), or nickel alloy (Inconel 625, Monel 400, Hastelloy C-276). The packing material may be flexible graphite, carbon fiber, PTFE, EPDM, NBR, etc. Typical bolting materials include ASTM A193 B7 / ASTM A194 2H, ASTM A193 B8, B8M/ ASTM A194 8, 8M.