Pipe for feeding slurry

Ceramic lined pipe for feeding slurry to agitation tank

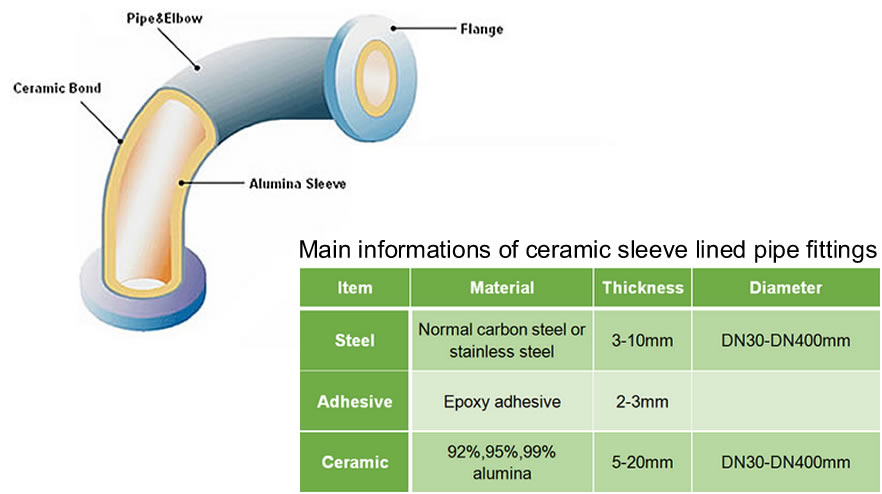

The wear resistant ceramic lined pipe (wear resistant ceramic pipe, cheap ceramic lined pipe) of the laminable tube is used to glue the ceramic sheet of alumina ceramic to the inner wall of the pipe with high temperature and high temperature.

Download PDFAfter the heating and curing, it forms a strong anti-friction layer. The production process of this product is relatively simple, the production cycle is short, the cost is relatively low.

Wear Resistant Ceramic Lined Pipe, also known as ceramic-lined pipe, is a type of pipe that has a ceramic layer bonded to the internal surface of the pipe. This specialized pipe is designed to handle highly abrasive materials and is commonly used in industries such as mining, power generation, and chemical processing where conventional pipes would wear out quickly.

The ceramic material used for lining the pipes is typically made from high-quality alumina, silicon carbide, or zirconium oxide. These materials are chosen for their exceptional hardness and resistance to wear, which is significantly higher than that of traditional steel pipes.

Hardness: Ceramic materials used in lining exhibit a high level of hardness, which is a measure of resistance to deformation. This property makes them ideal for withstanding the abrasive actions of materials that would quickly erode steel pipes.

Chemical Resistance: Ceramics are also known for their inertness to most chemicals, which means they do not react or degrade when in contact with corrosive substances. This characteristic is particularly beneficial in chemical processing applications.

The process of creating wear resistant ceramic lined pipes involves several steps, including the selection of the base pipe material, the application of the ceramic lining, and the curing process to ensure the bond is strong and durable.

Base Material Selection: The base pipe is typically made from carbon steel or stainless steel, depending on the specific requirements of the application. The choice of material is based on factors such as the corrosiveness of the material being transported and the pressure rating needed.

Ceramic Lining Application: The ceramic lining is applied to the interior surface of the pipe using a process that ensures a uniform and secure bond. This can involve techniques such as plasma spraying, slip casting, or hot isostatic pressing.

Curing Process: After the ceramic lining is applied, a curing process is necessary to harden the material and ensure a strong bond with the base pipe. This process can involve heat treatment or pressure application, depending on the specific materials and methods used.

The primary application of wear resistant ceramic lined pipes is in the transportation of slurries, powders, and granules that have a high potential to erode or wear down the pipe material. These pipes are particularly useful in processes involving the movement of coal, ash, minerals, and other abrasive substances.

| Items | Index |

|---|---|

| Alumina content | 92% |

| Bulk Density | 3.62g/cm³ |

| Rockwell Hardness (HRA) | 90 |

| Compressive Strength | 850MPa |

| Fracture Toughness | 4.8MPa.M1/2 |

| Bending Strength | 290MPa |

| Thermal Conductivity 20℃ | 20W/m.k |

| Coefficient of Thermal Expansion | 7.2×10-6m/×m.k |

| Young's Modulus 20℃ | 277GPa |

| Shear Modulus 20℃ | 113GPa |

| Surface Finish: As Fired | 1.27mm |

Wear-resisting bend (wear resistant ceramic pipe)just as its name implies is a relatively traditional is more wear-resisting bend (wear resistant ceramic pipe), adopted the new wear-resistant plastic production, used in large industrial, currently occupies the market share of around 80%.

Ceramic lined is an application that provides protection for materials in environments that experience exposure to extreme chemicals and temperatures.

Ceramic lined refers to a material or surface that has a layer of ceramic applied to it. This ceramic layer provides protection against wear, corrosion, and abrasion, making it ideal for use in industrial applications where harsh conditions can cause damage to equipment over time. Ceramic lining is commonly used in pipes, tanks, and other equipment used in chemical processing, mining, and power generation industries.

Ceramic liner pipe is a high technology production technology-self-fuel high temperature clutch synthesis method.

Ceramic Liner Composite pipe is a high technology production technology-self-fuel high temperature clutch synthesis method. The tube is composed of corundum ceramics, transition layer and steel three layers respectively from inside to outside, the ceramic layer is formed dense corundum porcelain (Al2O3) at high temperature above 2,200 ℃, and the steel pipe is formed firmly by the transition layer.

1. Good abrasion resistance

Ceramic lined pipe due to the inner lining of corundum ceramic (A-al2o3), the Mo hardness of up to 9.0 of the equivalent HRC90. Therefore, the metallurgical, electric power, mining, coal and other industries to transport the grinding medium has high wear resistance. The industrial operation confirms that its wear-resisting life is 10 times times or even dozens of times times that of quenched steel.

2. Small Operation resistance

corundum ceramic wear-resistant tube in the inner surface of smooth, and never rust, nor like seamless steel tube inside the surface has convex spiral. After testing the internal surface roughness and water resistance characteristics of the testing units, the smoothness of the inner surface is superior to any metal pipe, the resistance coefficient is 0.0193, slightly lower than the seamless pipe.

3, corrosion resistance, anti-scaling

Because the steel ceramic layer is (A-al2o3), it is a neutral trait. Therefore, with acid and alkali resistance and seawater corrosion, and at the same time with anti-scaling and other characteristics.

4. High temperature resistance and heat-resisting performance

The corundum ceramic (A-al2o3) is a single stable crystalline structure. Therefore, the composite pipe can operate in the -50--700℃ temperature range for a long time. Material linear expansion coefficient 6-8x10-6/0c, about 1/2 of steel pipe.

5. Low construction cost

corundum ceramic wear-resistant tube light weight, the price is suitable. The casting pipe with the same inner diameter is lighter than 50% and lighter than that of the wear-resistant alloy tube 20–30%.

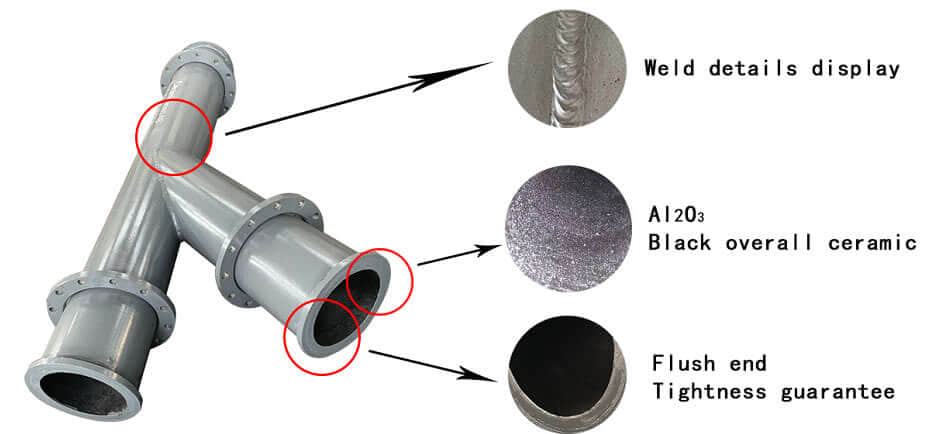

6. Convenient installation and construction

Because of the light weight of the tube, and good welding performance. Therefore, welding, flange, rapid connection and so on, construction and installation is convenient.

7. Ceramic lined pipe with the traditional steel pipe, wear-resistant alloy cast steel pipe, cast stone pipe as well as steel plastic, steel rubber pipe, etc. have essential differences. The outer layer of ceramic steel pipe is steel, and the inner is corundum. The Vickers hardness of corundum layer is as high as 100-1500 (Rockwell hardness is 90-98), which is equivalent to tungsten cobalt hard gold. The wear resistance is more than 20 times times higher than carbon steel pipe, it is superior to the corundum grinding wheel which is usually bonded.

Now the corundum grinding wheel is still the main grinding wheel of the grinding mill. The corundum layer in the ceramic steel tube can wear away the corundum grinding wheel. The abrasion resistance of ceramic steel tube is mainly by the inner layer of several millimeters thick corundum layer, its Morse hardness is 9, second only to diamond and SIC, in all oxides, its hardness is the highest.

There are probably hundreds of different methods for packing a abrasion resistant pipe and Elbows, and most of them have merit, but there are two principles that are vital for any method to work prevent rusting and Sea transportation security.

Wear-resistant ceramic composite pipe, full name ceramic liner composite steel pipe, is a kind of ceramic composite steel pipe.

Ceramic (Corundum: a-Al2O3) lined abrasion resistant straight pipe and fittings are lined with highly abrasion resistant ceramic by SHS -------Self-propagating High-temperature Synthetic process.

A small amount of iron also remains in the ceramic layer. There is a thin equiaxed grain area of alumina near the steel pipe wall, and then alumina was grown in form of dentrite to the surface of ceramic layer.

When abrasive material is transported through steel pipe in mining applications, typically as pumped slurry, the pipe can quickly be eroded from the inside out, which in more extreme cases can result in pipe leaks and even failure, or significant maintenance costs and downtime for pipe replacement.

Section of the composite pipe

Microstructure of ceramic layer

FeAl2O4 distributes among alumina dentrite. Although the ceramic layer was solidified from one end to another end of a pipe, the microstructure of ceramic layer was almost uniform throughout the whole length of the pipe.

Resistance to thermal shock

A composite elbow was used

in a mining plant for about

fifty thousands hours.

Hoop strength

Hoop strength is the resistance against radial pressure. The strength of the ceramic -lined steel composite pipe is 300 to 500MPa.

Compression-Shear strength

Compression-shear strength is the bonding strength at the interface between the ceramic layer and the steel pipe. The compression-shear strength of the ceramic-lined composite pipe is 15 to 20MPa.

Resistance to mechanical shock

The ceramic layer does not crack or flake off when the composite pipe receives a mechanical shock.

Resistance to thermal shock

The ceramic layer does not crack or flake off when heated to 800℃ and then quenched.

Resistance to abrasion

The ceramic-lined steel composite pipe has exceptional resistance to abrasion. Its service life in materials transportation with hard abrasives is more than 20 times longer than in common steel pipe.

For these abrasive applications, mild steel pipe is not tough enough to stand up to the abuse for more than a year or two. As a result, maintenance engineers are seeking superior piping alternatives to reduce maintenance and prolong system life, at a price point that will not significantly impact the budget.

The general servicelife of common steel elbow is about 700 hours.

The ceramic-lined steel composite pipe can be joined by welding the steel pipe layer.

The ceramic-lined steel composite pipes are lighter than alloy pipes, cast iron pipes, and cast stone pipes, which reduces the expense of transportation and makes the pipes easier to install.

Good weld ability

The relative weight of the

composite pipe is about

40-50% lighter than that of the

caststone pipe

The ceramic-lined steel composite pipes can be easily connected by welding, or with flanges and soft easy connectors.

Convenient installation

The composite pipes have good corrosion-resistant. There is no evidence of corrosion filling the composite pipes with bitter for one year (left), but the common steel pipe under the same condition is corroded seriously (right).

Ceramic liner composite pipe is different from traditional seamless steel pipe, wear-resisting alloy cast steel pipe, cast stone pipe, steel plastic pipe and steel rubber pipe.

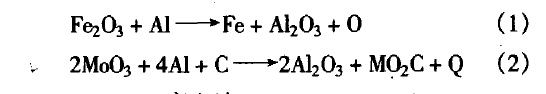

Self-propagating high temperature synthesis (SHS) is used to describe a process in which the initial reagents (usually powders), when ignited, spontaneously transform into products due to the exothermitic heat of reaction.

A well-known example of SHS reaction is the thermite reaction given below:

This reaction generates temperatures above the melting point of alumina and is used in the thermit welding process for joining railway lines.

Several other terminologies - such as combustion synthesis, gasless combustion or self-propagating exothermic reaction - are used to describe the process.

The types of material that can be formed using this process include metal borides, silicides, carbides, nitrides, sulphides, aluminides and oxides.

The combination of high rigidity of ceramic and high elasticity of steel gives the pipe unmatchable features as an abrasion resistant, heat resistant and corrosion resistant material for use in the fields of power generation, metallurgy, mining, and chemical industry etc.. It has many advantages over steel pipes, cast stone pipes, and steel-plastic compound pipes.

The composite pipe is composed of three layers: ceramic, intermediate, and steel layers. The ceramic layer is formed by molten alumina at a temperature above 2500 degree.

The molten alumina produced from the reaction Fe2O3+2Al=2Fe+Al2O3 spreads on the inside wall of the steel pipe under the influence of a centrifugal force, then solidifies, so the ceramic layer has high density and smooth surface and bonds to the steel pipe. They are widely used to convey highly abrasive material such as fly ash and any other fine powder material in mine, thermo power generating, coal processing plant, metallurgy, construction, etc. The service life is 10 to 20 times longer than normal steel pipe.