Basalt Lining Tiles

Durable basalt lining tiles designed for wear resistance in industrial applications.

Discover the durability and elegance of Cast Stone Guide Rails, offering robust support for construction projects.

Crafted for durability and timeless elegance, these guide rails provide robust support for various projects. Elevate your infrastructure with customizable designs, blending seamlessly into any architectural vision. Explore the perfect synergy of strength and style for long-lasting, visually stunning constructions. Trust in the reliability of Cast Stone Guide Rails – where safety meets sophistication.

Cast stone guide rails are commonly used in construction projects as a durable and attractive option for guiding pedestrian traffic, especially in outdoor or high-traffic areas. They are often designed to resemble natural stone materials such as limestone, sandstone, or granite.

Basalt, on the other hand, is a naturally occurring volcanic rock that is not commonly used as a primary material for guide rails. However, it is sometimes used as an aggregate in the mixtures used to make cast stone, which can give the final product a unique texture and appearance.

In summary, cast stone guide rail is not made from cast basalt, but basalt may be used as an aggregate in the mixture used to make the cast stone product. Cast stone is a man-made material that is designed to resemble natural stone and is often used for architectural and decorative purposes.

Cast stone guide rails, often an overlooked component, play a pivotal role in enhancing both safety and visual appeal. Let's delve into the world of cast stone guide rails, exploring their benefits, installation process, maintenance tips, applications, cost considerations, and more.

Comparison of Ceramic lines with few other materials under standard conditions :

| Material | Thickness(mm) | Approx life ( Months ) |

|---|---|---|

| Mild Steel | 10 | 3-5 |

| Cast Iron | 20 | 6-8 |

| Ni-Hard | 20 | 12-14 |

| Cast Basalt | 30 | 20-25 |

| Ceramic | 10 | 35-40 |

Hard & Compact Smooth & Inner Withstands High-Abrasion & Corrosion In any of the process industries especially Sled and Cement corrosion and abrasion lead to significant downtime of the plant. Further, the useful life or the equipment itself may get impaired because of the high abrasive nature of the materials being used. Thus, ‘wear mechanism’ results in hut down, replacement, etc., which is costly, resulting in loss to tilt: tunic of millions of dollars.

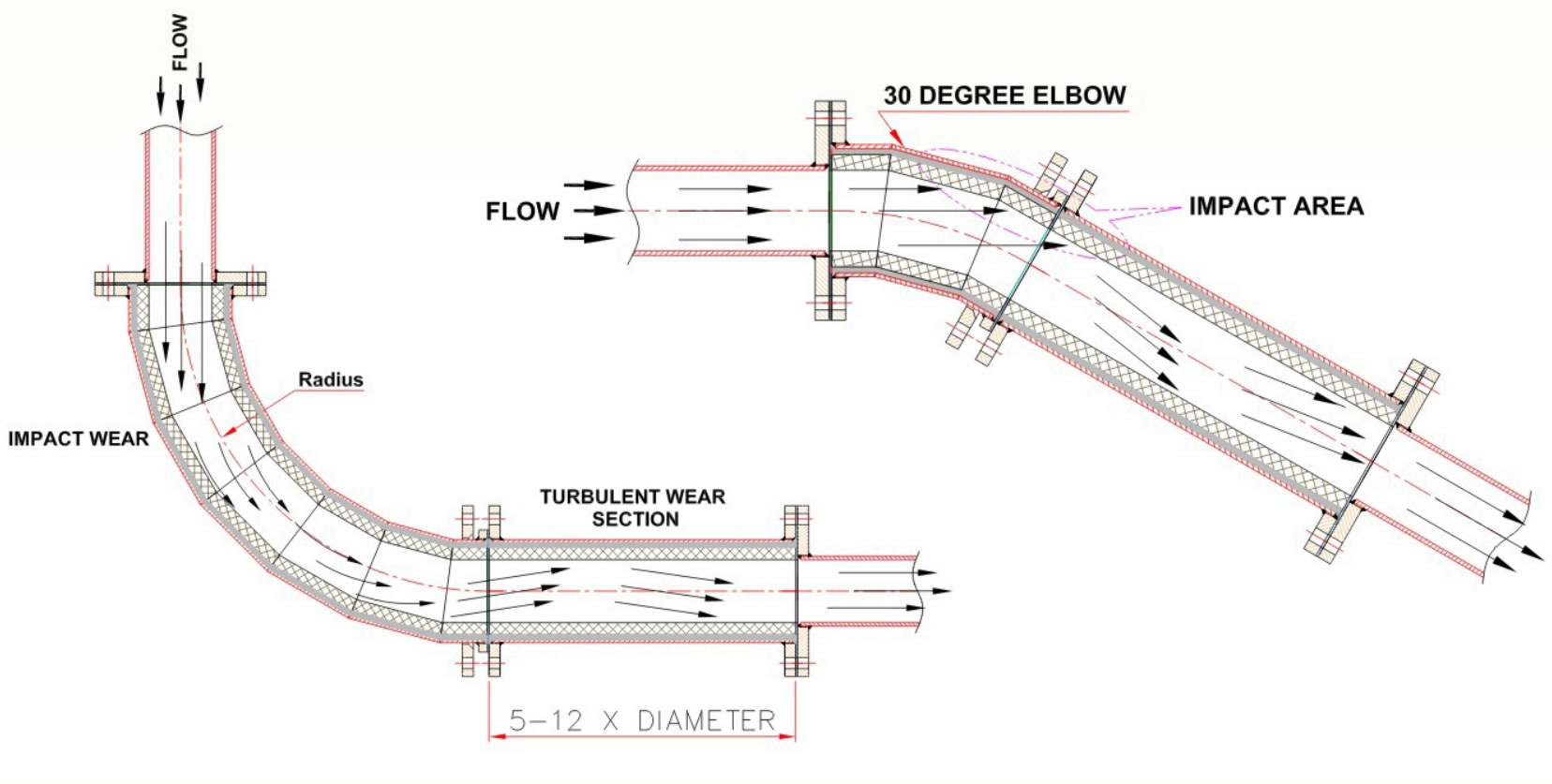

The bend radius should be minimum 3 times of the nominal bore. At discharge end of each bend, cast basalt lined straight pipe of length 5 to 12 times the nominal bore must be used.