Galvanized mild steel pipe

Mild Steel Pipe Galvanized is a tubular shaped pipe of galvanized Mild Steel.

Hot-dip galvanizing (HDG), as referenced is the process of dipping fabricated steel into a kettle or vat of molten zinc.

Hot-dip galvanizing (HDG) is the process of coating iron, steel or ferrous materials with a layer of zinc. This done by passing the metal through molten zinc at a temperature of 860°F (460°C) to form zinc carbonate (ZNC03). Zinc carbonate is a strong material that protects steel and can prevent corrosion in many circumstances. Hot-dip galvanizing can be carried out cheaply and in large batches.

Because the pipes are galvanized, it is protected from rust and corrosion. Steel rusts after interacting with water or moisture in the air over time. By adding a coating of zinc to the tubing, galvanized steel round tubing corrodes much slower, extending the life of your tubing.

In addition to this, galvanized pipe also provides:

Galvanizing is one of the most widely used to methods for protecting metal from corrosion. It involves applying a thin coating of zinc to a thicker base metal, helping to shield it from the surrounding environment. The next time you are in your car, take a look at the street signs and lamp posts you pass. A large number of them will have a mute, silver color on them. That "silver" is actually the coating of zinc.

Thus, PE Coated Steel Pipes have been highly acclaimed even under severe environments such as areas of extreme cold, desert regions and under the sea.

Preparation: The galvanizing reaction will only occur on a chemically clean surface, so the first step of the process involves removing contamination. First, the metal is degreased using a caustic solution and then dipped in hydrochloric acid to remove rust, mill scale, welding slag, paint and grease. This followed by a rinse and a dip in a flux solution, which is usually about 30 percent zinc ammonium chloride.

Galvanizing: When the clean iron or steel component is dipped into the molten zinc (at 842°F (450°C)), zinc-iron alloy layers form as a result of a metallurgical reaction between the iron and zinc. When the material is pulled from the galvanizing bath, a layer of molten zinc is present on top of the alloy layer. When it cools, it has the bright, shiny appearance associated with galvanized products.

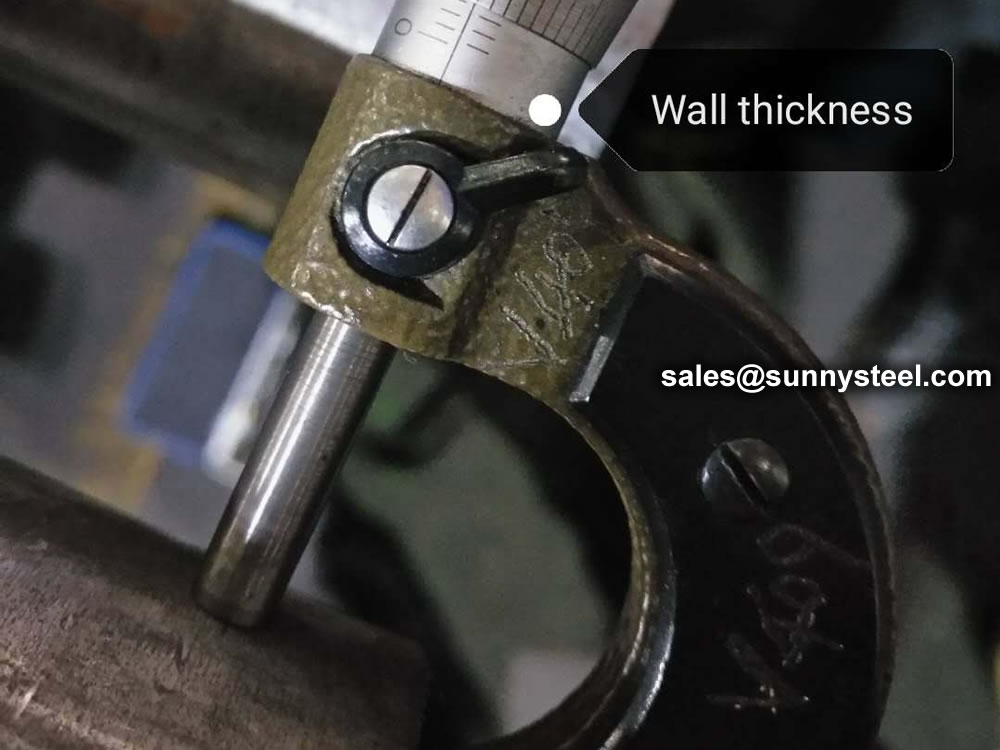

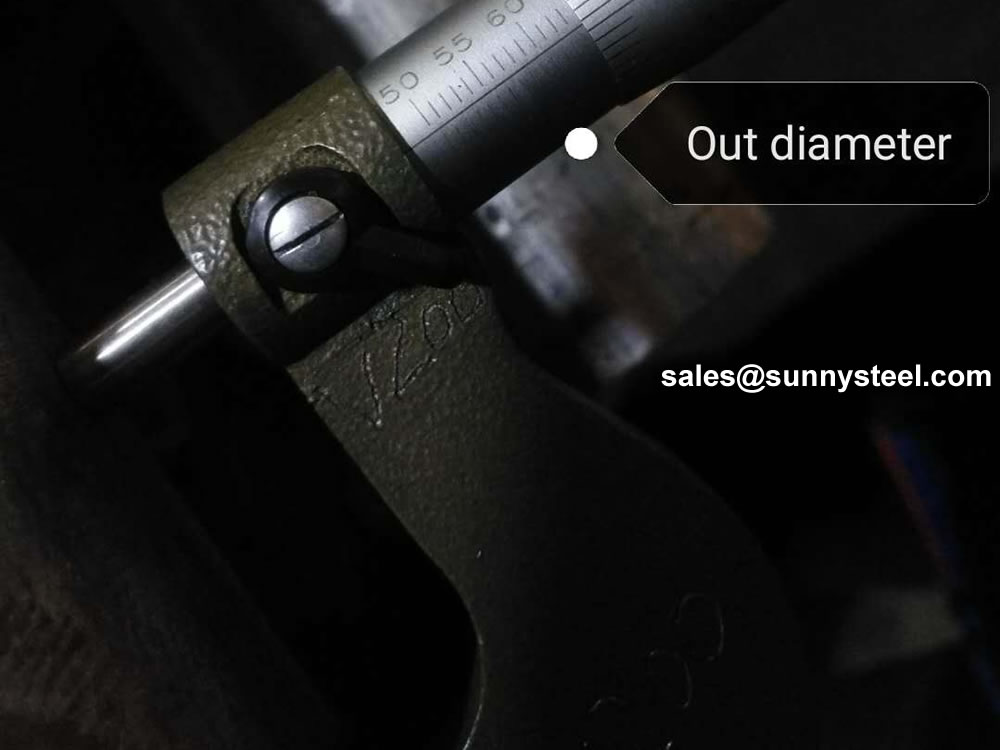

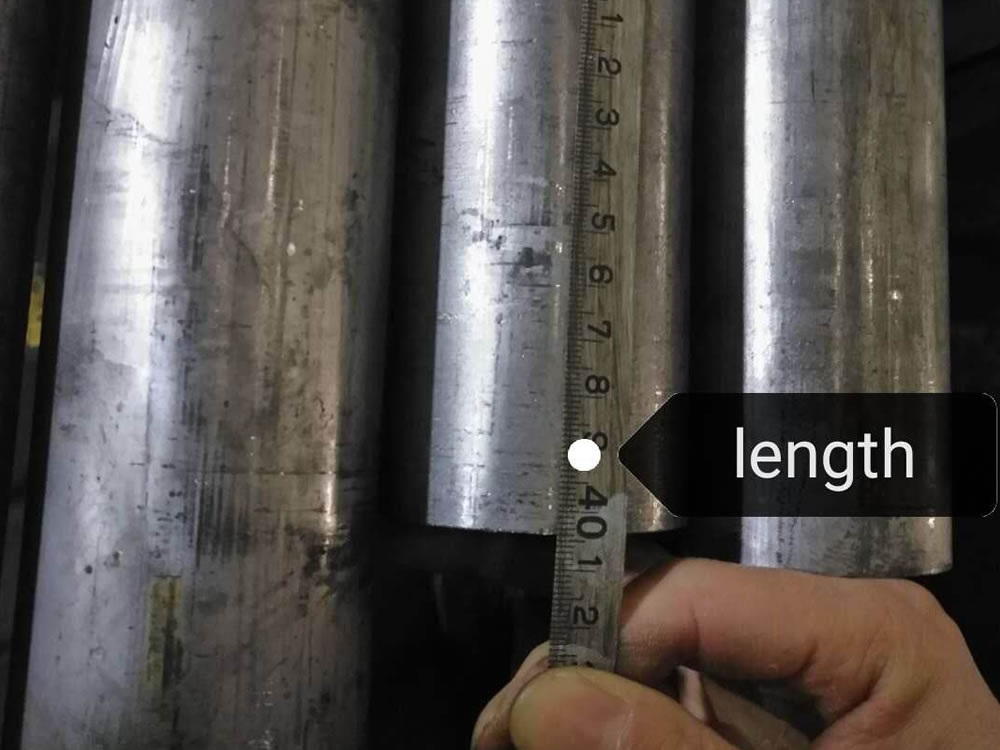

Inspection: After galvanizing, the coated materials are inspected for coating thickness and coating appearance. A variety of simple physical and laboratory tests may be performed to determine thickness, uniformity, adherence and appearance of the zinc coating.

Galvanized steel is produced by coating the steel in zinc. The properties of galvanized steel are a unique combination that make it ideal for use in interior and exterior applications such as car bodies, appliances, nuts and bolts, roofs, and rebar.

According to the American Galvanizers Association, galvanized steel resists corrosion up to 100 times better than uncoated steel.

All galvanized steel has a matte-gray appearance. Zinc coating applied by using electrogalvanizing is smoother than galvanized steel made with batch or continuous galvanizing and allows for a higher quality finish when painted.

The zinc coating on galvanized steel is resistant to cracking and loss of adhesion when the steel is formed into a product.

The zinc coating does not require special handling to protect it during transport or use. It is extremely durable and resistant to scratches from abrasion.

Steel is by far the most recycled material in North America. Galvanized steel is as recyclable as other types of steel.

Water and gas require the use of pipes to carry them into residential homes and commercial buildings. Gas supplies power to stoves, water heaters and other devices, while water is essential for other human needs. The two most common types of pipes used to carry water and gas are black steel pipe and galvanized steel pipe.

Galvanized pipe is covered with a zinc material to make the steel pipe more resistant to corrosion. The primary use of galvanized pipe is to carry water to homes and commercial buildings. The zinc also prevents the buildup of mineral deposits that can clog the water line. Galvanized pipe is commonly used as scaffolding frames because of its resistance to corrosion.

Black steel pipe is different from galvanized pipe because it is uncoated. The dark color comes from the iron-oxide formed on its surface during manufacturing. The primary purpose of black steel pipe is to carry propane or natural gas into residential homes and commercial buildings. The pipe is manufactured without a seam, making it a better pipe to carry gas. The black steel pipe is also used for fire sprinkler systems because it is more fire-resistant than galvanized pipe.

The zinc on galvanized pipe flakes off over time, clogging the pipe. The flaking can cause the pipe to burst. Utilizing galvanized pipe to carry gas can create a hazard. Black steel pipe, on the other hand, corrodes more easily than galvanized pipe and allows minerals from water to build up inside it.

Galvanized steel pipe costs more than black steel pipe because of the zinc coating and manufacturing process involved in producing galvanized pipe. Galvanized fittings also cost more than the fittings used on black steel. Galvanized steel pipe must never be joined with black steel pipe during the construction of a residential home or commercial building.

Quite simply, galvanizing a metal gives it anti-corrosion properties. Without the protective zinc coating, the metal would remain exposed to the elements and potentially oxidize and corrode much faster. Galvanized Steel is a cost effective alternative to using materials such as austenitic stainless steel or aluminum in order to prevent corrosion.

Galvanizing can protect metal is a number of ways. Firstly, it creates a protective coating that shields the metal from the surrounding environment. The layer of zinc prevents water and moisture and other elements in the air from corroding the steel underneath. Should the zinc coating be scratched deep enough, the metal would become exposed and susceptible to corrosion.

Galvanizing can also protect metal through a process called "galvanic corrosion". Galvanic corrosion occurs when two metals of a different electrochemical make up are placed into contact with one another with an electrolyte present, such as salty water. Depending on the atomic structure of the two metals, one metal is the anode and the other is the cathode. The anode corrodes more rapidly than it would by itself and the cathode corrodes at a slower pace than it would by itself. The reason zinc is used for galvanizing is because it has an affinity towards being the anode when in contact with many different types of metals. Since the zinc coating in contact with the base metal is usually the anode, it slows the corrosion of the base metal, or the cathode.

There are several different processes for galvanizing metal:

As the name implies, this method involves dipping the base metal into a molten pool of zinc. First, the base metal must be cleaned either mechanically, chemically, or both to assure a quality bond can be made between the base metal and the zinc coating. Once cleaned, the base metal is then fluxed to rid it of any residual oxides that might remain after the cleaning process. The base metal is then dipped into a liquid bath of heated zinc and a metallurgical bond is formed.

The advantages of this method are that it is economical; it can be performed quickly and to complex shapes. However, the final coating can be inconsistent relative to other galvanizing processes.

This method is very similar to hot-dip galvanizing but is performed at the steel mill, usually on materials that already have a specific shape. Pre-galvanizing involves rolling metal sheet through a similar cleaning process to that of the hot-dip galvanizing process. The metal is then passed through a pool of hot, liquid zinc and then recoiled.

An advantage of this method is that large coils of steel sheet can be rapidly galvanized with a more uniform coating compared to hot-dip galvanizing. A disadvantage is that once fabrication of the pre-galvanized metal begins, exposed, uncoated areas will become present. This means that when a long coil of sheet is cut into smaller sizes, the edges where the metal is cut are left exposed.

Unlike the previous processes, electrogalvanizing does not use a molten bath of zinc. Instead, this process utilizes an electrical current in an electrolyte solution to transfer zinc ions onto the base metal. This involves electrically reducing positively charged zinc ions to zinc metal which are then deposited on the positively charged material. Grain refiners can also be added which helps to ensure a smooth zinc coating on the steel. Similar to the pre-galvanizing process, electrogalvanizing is typically applied continuously to a roll of sheet metal.

Some advantages of this process are a uniform coating and precise coating thickness. However, the coating is typically thinner than the coating of zinc achieved by the hot-dip galvanizing method which can result in reduced corrosion protection.

Typically used on pipe 3" and smaller, threaded connections are referred to as screwed pipe. With tapered grooves cut into the ends of a run of pipe, screwed pipe and screwed fittings can easily be assembled without welding or other permanent means of attachment. In the United States, the standard pipe thread is National Pipe Thread (NPT).

The reason for this is that as NPT connections are assembled, they become increasingly more difficult for the process to leak. The standard taper for NPT pipe is 3/4" for every foot. Threaded End is abbreviated on drawings as TE.

Threaded fittings have threads that are either male or female. Male threads are cut into the outside of a pipe or fitting, while female threads are cut into the inside of the fitting. As screwed pipe and fittings are assembled, two pieces are pulled together. The distance that is pulled together is called the thread engagement.

| Product Name | Executive Standard | Dimension (mm) | Steel Code / Steel Grade |

|---|---|---|---|

| Casting | API 5CT | Ø48.3~273 x WT2.77~11.43 | J55, K55, N80, L80 |

| Tubing | API 5CT | Ø48.3~273 x WT2.77~11.43 | J55, K55, N80, L80, H40 |

| Product Name | Executive Standard | Dimension (mm) | Steel Code / Steel Grade |

|---|---|---|---|

| Line Pipes | API 5L | Ø60.3~273.1 x WT2.77~12.7 | A25, A, B, X42, X46, X52, X56, X60, X65, X70, X80 |

| Product Name | Executive Standard | Dimension (mm) | Steel Code / Steel Grade |

|---|---|---|---|

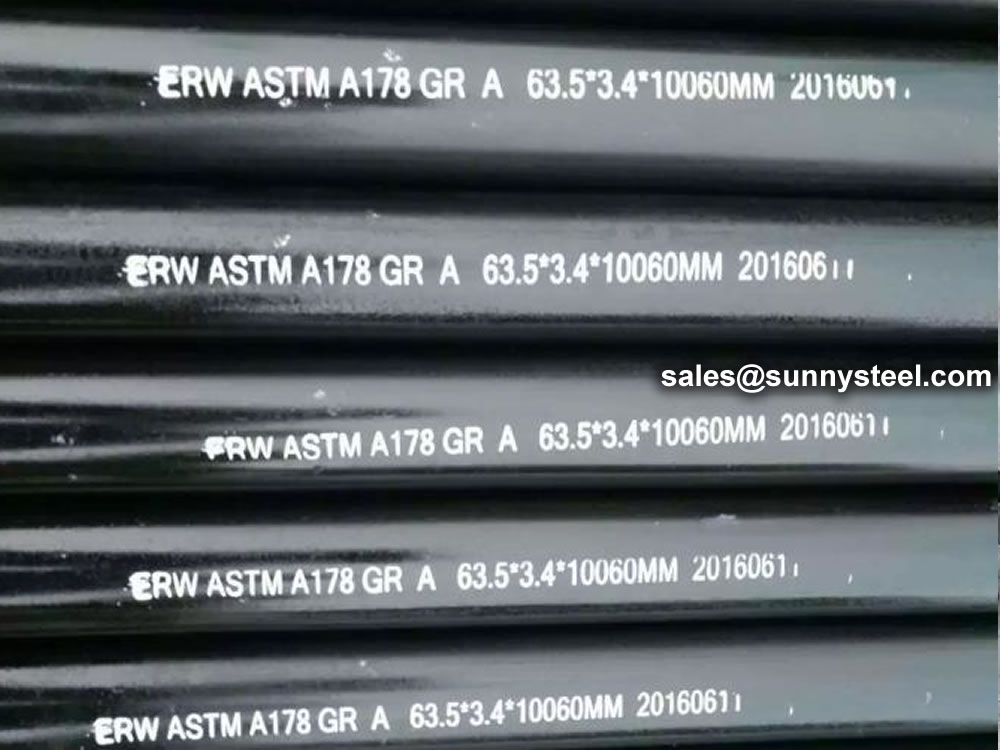

| Electric-Resistance-Welded Steel Pipes | ASTM A135 | Ø42.2~114.3 x WT2.11~2.63 | A |

| Electric-Resistance-Welded Carbon Steel and Carbon-Manganese Steel Boiler and Superheater Tubes | ASTM A178 | 42.2-114.3 x 2.11-2.63 | A, C, D |

| ERW and Hot-dip Galvanized Steel Pipes | ASTM A53 | Ø21.3~273 x WT2.11~12.7 | A, B |

| Pipes for Piling Usage | ASTM A252 | Ø219.1~508 x WT3.6~12.7 | Gr.2, Gr.3 |

| Tubes for General Structural Purpose | ASTM A500 | Ø21.3~273 x WT2.11~12.7 | Gr.2, Gr.3 |

| Square Pipes for General Structural Purpose | ASTM A500 | 25 x 25~160 x 160 x WT1.2~8.0 | Carbon Steel |

| Product Name | Executive Standard | Dimension (mm) | Steel Code / Steel Grade |

|---|---|---|---|

| Threaded Steel Pipes | DIN 2440 | Ø21~164 x WT2.65~4.85 | Carbon Steel |

| Product Name | Executive Standard | Dimension (mm) | Steel Code / Steel Grade |

|---|---|---|---|

| Screwed and Socketed Steel Tubes | BS 1387 | Ø21.4~113.9 x WT2~3.6 | Carbon Steel |

| Scaffolding Pipes | EN 39 | Ø48.3 x WT3.2~4 | Carbon Steel |

| Product Name | Executive Standard | Dimension (mm) | Steel Code / Steel Grade |

|---|---|---|---|

| Carbon Steel Tubes for General Structure Purpose | JIS G3444 | Ø21.7~216.3 x WT2.0~6.0 | Carbon Steel |

| Carbon Steel Tubes for Machine Structure Purpose | JIS G3445 | Ø15~76 x WT0.7~3.0 | STKM11A, STKM13A |

| Carbon Steel Pipes for Ordinary Piping | JIS G3452 | Ø21.9~216.3 x WT2.8~5.8 | Carbon Steel |

| Carbon Steel Pipes for Pressure Service | JIS G3454 | Ø21.7~216.3 x WT2.8~7.1 | Carbon Steel |

| Carbon Steel Rigid Steel Conduits | JIS G8305 | Ø21~113.4 x WT1.2~3.5 | G16~G104, C19~C75, E19~E75 |

| Carbon Steel Rectangular Pipes for General Structure | JIS G3466 | 16 x 16~150 x 150 x WT0.7~6 | Carbon Steel |

The alloy content of the coil is often lower than similar grades of steel plate, improving the weldability of the spiral welded pipe. Due to the rolling direction of spiral welded pipe coil is not perpendicular to the pipe axis direction, the crack resistance of the spiral welded pipe materials.

Welded steel pipe refers to a steel pipe with seams on the surface that is welded by bending and deforming a steel strip or steel plate into a circular, square or other shape. The blanks used for welded steel pipes are steel sheets or strips.

Since the 1930s, with the rapid development of continuous rolling production of high-quality strip steel and the advancement of welding and inspection technology, the quality of welds has been continuously improved, and the varieties and specifications of welded steel pipes have been increasing.

When the T-shaped welded steel pipe contains Ni, it has strong corrosion resistance in an acidic environment. In an environment containing sulfuric acid or hydrochloric acid, the higher the Ni content in the T-shaped welded steel pipe, the stronger the corrosion resistance. Under normal circumstances, only adding Cr to the T-shaped welded steel pipe can prevent the phenomenon of corrosion. The poor edge condition of the strip is another important cause of misalignment. The effects of changes in mass flow, heat flow density and structural parameters (ratio of helical curvature diameter to T-shaped welded steel pipe diameter Dc/D) on the heat transfer coefficient of saturated bubble boiling in vertical spiral pipes.

During the production of T-shaped welded steel pipes, misalignment occurs from time to time, and there are many influencing factors. In production practice, the steel pipe is often degraded by the wrong side and out of tolerance. Therefore, it is necessary to analyze the reasons for the misalignment of the spiral steel pipe and its preventive measures.

Due to the poor shape and dimensional accuracy of the head and tail of the uncut steel strip, it is easy to cause the steel strip to bend hard and cause misalignment during butt joint. Simulation parameter range: vertical pipe: pipe diameter D=10mm, pipe length L=660mm; three types of vertical T-shaped welded steel pipe: pipe diameter D=10mm, the change of the ratio of the curvature diameter of the T-shaped welded steel pipe to the spiral pipe diameter is Dc /D=15, 20, 25, helical pitch Pt=20mm, tube lengths are L=503mm, L=660mm, L=817mm respectively. Mass flow G=200~400Kg/(m'2 s), heat flux density q=5~15KW/m'2, saturation pressure p, saturation=0.414880MPa, saturation temperature T, saturation=283.15K.

The technical requirements and inspection of welded pipes are based on the provisions of the GB3092 "Welded Steel Pipes for Low-Pressure Fluid Transmission". It can be delivered according to fixed length or double length. The surface of the steel pipe should be smooth, and defects such as folds, cracks, delamination, and lap welding are not allowed. The surface of the steel pipe is allowed to have minor defects such as scratches, scratches, weld misalignment, burns and scars that do not exceed the negative deviation of the wall thickness. The thickening of the wall thickness and the presence of inner seam weld bars are allowed at the weld.

Welded steel pipes should be subjected to mechanical performance test, flattening test and flaring test, and must meet the requirements of the standard. When the steel pipe should be able to withstand the internal pressure, carry out a pressure test of 2.5Mpa, and keep it for one minute without leakage. The method of eddy current flaw detection is allowed to replace the hydrostatic test. The eddy current flaw detection is carried out according to the standard of GB7735 "Steel tube eddy current flaw detection inspection method". The eddy current flaw detection method is to fix the probe on the frame, keep a distance of 3~5mm between the flaw detection and the weld seam, and conduct a comprehensive scan of the weld seam by the rapid movement of the steel pipe. The flaw detection signal is automatically processed and sorted by the eddy current flaw detector. To achieve the purpose of flaw detection. The welded pipe after the flaw detection is cut off according to the specified length with a flying saw, and it is rolled off the assembly line through the turning frame. Both ends of the steel pipe should be chamfered with flat ends, printed with marks, and the finished pipes are packed in hexagonal bundles before leaving the factory.

Straight seam steel pipe is a steel pipe whose weld seam is parallel to the longitudinal direction of the steel pipe. Generally, its strength is higher than that of straight seam welded pipe. Narrower billets can be used to produce welded pipes with larger diameters, and the same width of billets can be used to produce welded pipes with different pipe diameters. But compared with the straight seam pipe of the same length, the weld length is increased by 30~100%, and the production speed is lower. So what are its processing methods?

The surface quenching and tempering heat treatment of straight seam welded pipe is usually carried out by induction heating or flame heating. The main technical parameters are surface hardness, local hardness and effective hardened layer depth. Vickers hardness tester can be used for hardness testing, and Rockwell or superficial Rockwell hardness tester can also be used. When the surface heat treatment hardened layer is thick, the Rockwell hardness tester can also be used. When the thickness of the heat-treated hardened layer is 0.4-0.8mm, the HRA scale can be used, and when the thickness of the hardened layer exceeds 0.8mm, the HRC scale can be used.

If the parts require high local hardness, local quenching heat treatment can be carried out by means of induction heating. Such longitudinal welded pipes usually need to mark the location of local quenching heat treatment and local hardness value on the drawing. Hardness testing of longitudinally welded pipes shall be carried out in the area. The hardness testing instrument can use a Rockwell hardness tester to test the HRC hardness value. If the heat-treated hardened layer is shallow, a surface Rockwell hardness tester can be used to test the HRN hardness value.

The three hardness values of Vickers, Rockwell and Superficial Rockwell can be easily converted to each other and converted into hardness values required by standards, drawings or users. The corresponding conversion tables are given in the international standard ISO, the American standard ASTM and the Chinese standard GB/T.