Stainless Steel Grade 310 is a medium carbon austenitic stainless steel, for high temperature applications such as furnace and heat treatment equipment.

310S stainless steel plates offer a combination of high-temperature resistance, corrosion resistance, and mechanical strength, making them an ideal choice for demanding applications in industries such as power generation, oil and gas, and chemical processing. For projects requiring a material that can endure extreme temperatures while maintaining structural integrity, 310S stainless steel is a top-tier option.

310S stainless steel sheets is similar to stainless steel 310 apart from a lower content of carbon that reduces carbideprecipitation and enhances weldability. The soaring nickel and chromium contents of ss 310s plates offer similar corrosionresistance, higher resistance to oxidation and the holding of a superior portion of room temp potency than the usual austeniticsteel such as S304.

AISI 310S stainless steel is a high-temperature resistant austenitic stainless steel with excellent mechanical properties, oxidation resistance, and heat resistance due to its high chromium and nickel content. It is known for its superior corrosion resistance, especially in comparison to the common austenitic alloys like Type 304, and retains a larger fraction of room temperature strength.

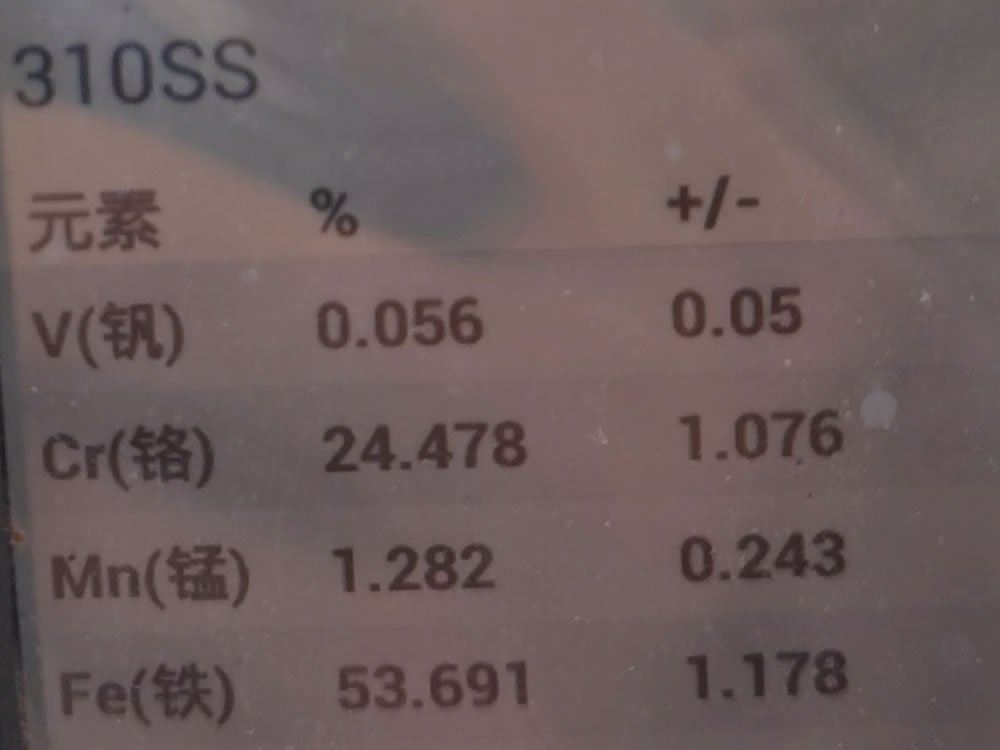

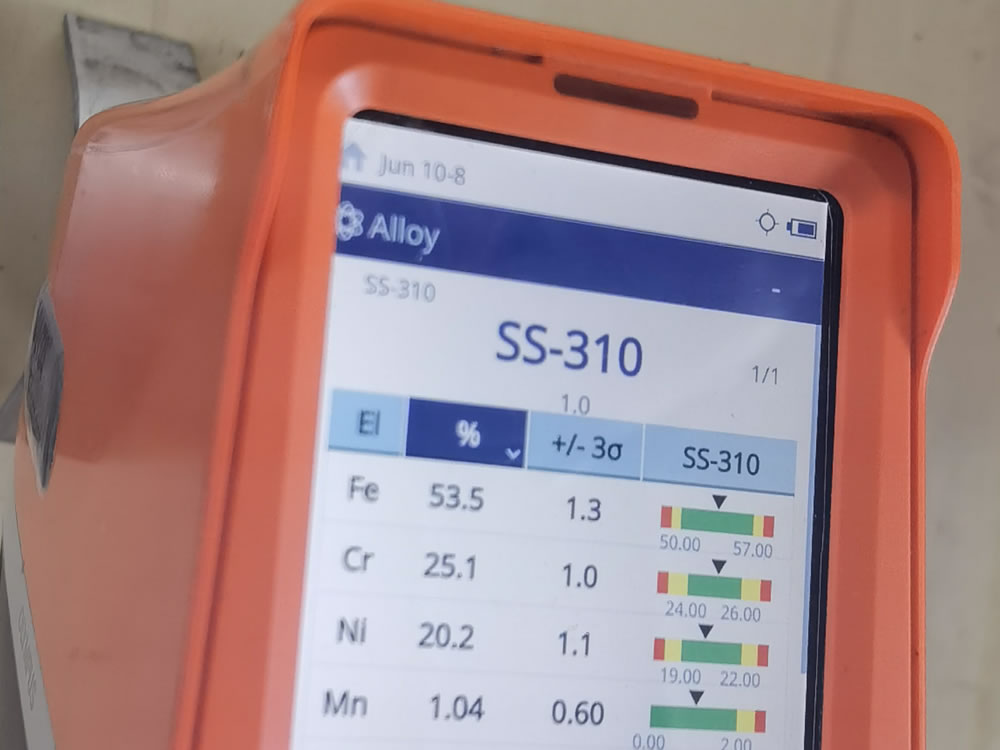

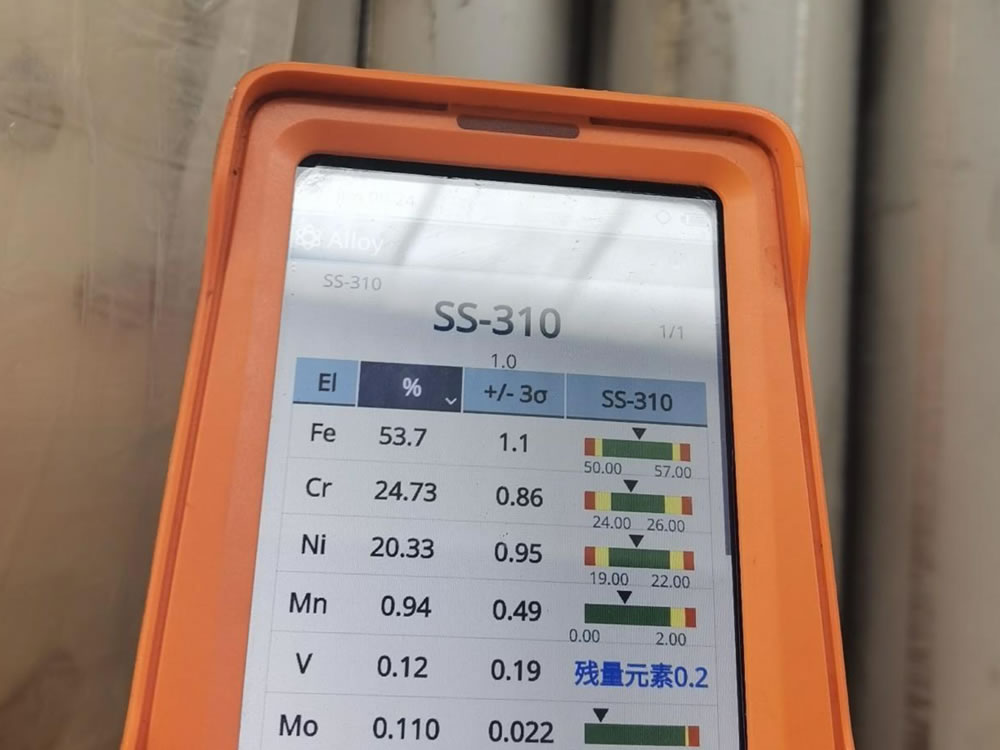

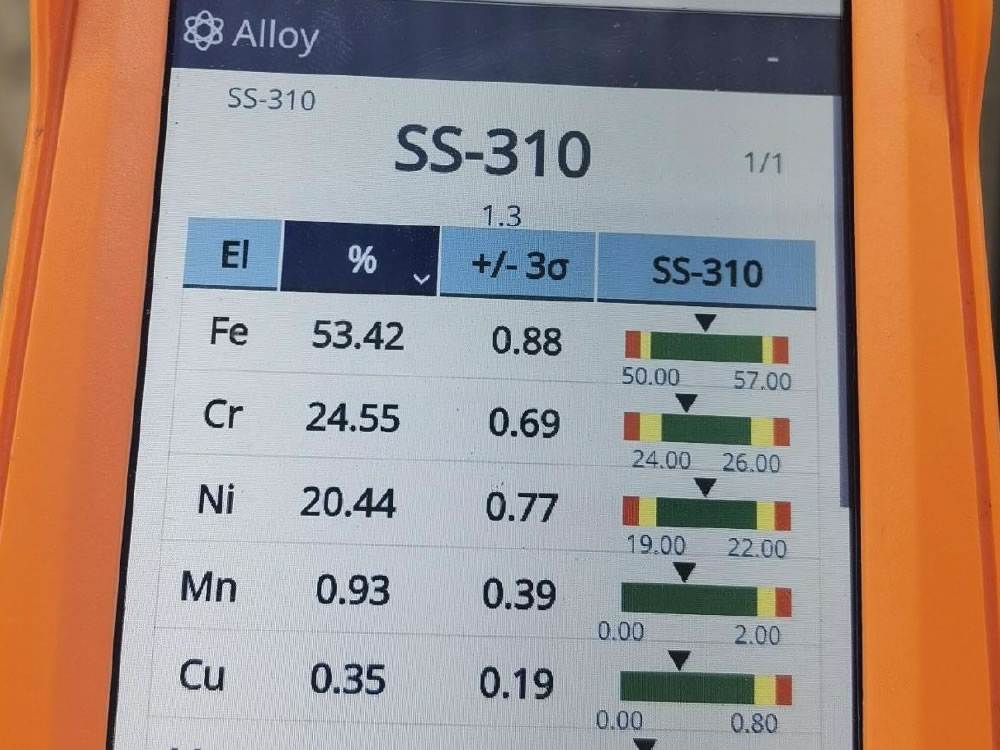

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Fe |

|---|---|---|---|---|---|---|---|---|---|

| SS 310 | 0.015 max | 2.0 max | 0.15 max | 0.020 max | 0.015 max | 24.00 – 26.00 | 0.10 max | 19.00 – 21.00 | 54.7 min |

| SS 310S | 0.08 max | 2.0 max | 1.00 max | 0.045 max | 0.030 max | 24.00 – 26.00 | 0.75 max | 19.00 – 21.00 | 53.095 min |

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

|---|---|---|---|---|---|---|---|

| SS 310 | 1.4841 | S31000 | SUS 310 | 310S24 | 20Ch25N20S2 | - | X15CrNi25-20 |

| SS 310S | 1.4845 | S31008 | SUS 310S | 310S16 | 20Ch23N18 | - | X8CrNi25-21 |

| Item | UNS | ASTM | ASME | AMS |

|---|---|---|---|---|

| 310 | UNS S31000 | ASTM A240 | ASME SA240 | AMS 5521 |

| 310S | UNS S31008 | ASTM A240 | ASME SA240 | AMS 5521 |

| 310H | UNS S31009 | ASTM A240 | ASME SA240 | AMS 5521 |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|

| 7.9 g/cm3 | 1402 °C (2555 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 0.4 |

Alloy 310 can be easily welded and processed by standard shop fabrication practices.

The 310S grade is particularly chosen for applications that involve moist corrodents at temperatures lower than what is typically considered "high temperature" service due to its lower carbon content compared to the standard 310 grade. This makes 310S less prone to embrittlement and sensitization in service.

For high-temperature applications, 310H, a variant with a higher carbon content, is preferred for its better creep strength. However, 310H may be prone to sigma phase embrittlement in the temperature range of 650–900°C.

When it comes to corrosion resistance, while 310S has good aqueous corrosion resistance, it lacks molybdenum, making it less resistant to pitting than grades like 316. It is also susceptible to sensitization and intergranular corrosion after exposure to elevated temperatures or welding.

The 310S stainless steel is available in various forms such as plate, sheet, strip, bar, rod, tube, pipe, and wire, and can be supplied with different surface finishes. It is also commonly produced in "Dual Certified" form, mainly in plate and pipe, which means it meets the specifications for both 310H and 310S.

It is used in various industrial applications such as furnace parts, heat treatment equipment, heat exchangers, and in environments where it may be exposed to high temperatures and corrosive conditions.

Applications for these grades of stainless steel plate include the manufacture of cryogenic components and use in furnaces, particularly in the construction of burners, recuperators, doors, fans and pipework. As these grades of stainless steel can withstand very high temperatures, they are also commonly used in the food processing, chemical and pharmaceutical industries. They are also used in fluidised bed furnaces, coal burners, grilles, pipework and air ducts. Ore and steel processing plants also utilise the unique properties of this stainless steel plate in smelting, steel melting and continuous casting equipment. These grades are also widely used in the petroleum refining industry, particularly in catalytic recovery systems, flares, recuperators and pipe hangers. This grade is used in power generation applications; it is used in coal gasifier internals, pulverised coal burners and tube hangers. Sintering and cement plants also utilise the properties of this stainless steel plate in burners and burner shields, feed and discharge systems and wind boxes. Another industry where these grades of stainless steel are widely used is in the thermal processing industry. It can be found in annealing covers and boxes, burner grates, doors, fans, mufflers, retorts and walking beams. These grades of stainless steel plate can withstand very high temperatures, making them useful in a wide range of industries.

310S stainless steel plates are used in a variety of high-demand applications across different industries:

310S grade is a steel comprising of low concentration of carbon. Stainless steel 310S alloy is made of 25% chromium and 20% nickel that make it widely resistant to oxidation and corrosion. The nominal carbon magnitude makes it less inclined to embrittlement and sensitization while in use.

310 plate contains no more than 0.25% carbon while 310S contains at most 0.08% carbon. 310H stainless steel is comprised of between 0.04% and 0.1% carbon. 310, 310S and 310H stainless steel plate all contain 2.0% manganese, 0.045% phosphorous and 0.30% sulfur.

While 304 is flexible and profitable with excellent corrosion resistance, 310/S shines in high-temperature applications with dominating oxidation resistance. Considering the application, environmental conditions, and cost-effectiveness decide the most acceptable stainless-steel grade for your project.

Type 310 has good sulfidation resistance and good resistance to carburization in moderately carburizing atmospheres.

310S (UNS S31008) is the low carbon version of the alloy. It is utilized for ease of fabrication. 310H (UNS S31009) is a high carbon modification developed for enhanced creep resistance. In most instances the grain size and carbon content of the plate can meet both the 310S and 310H requirements.

310 has a machinability rating of 42% relative to AISI B1112 steel. When using high speed steel tooling, this equates to about 70 surface feet per minute. Forming operations should be performed at room temperature whenever possible. Welding with AWS E310-15 electrodes or ER310 bare wire is suggested.

SS 310: Designed for high-temperature applications, offering excellent strength and oxidation resistance at elevated temperatures. SS 316: While suitable for moderate temperatures, SS 316 may experience reduced corrosion resistance compared to SS 310 in high-temperature environments.

If it has an austenite structure, then it will not be magnetic. In other words, ferritic grades of stainless steel are magnetic, such as grades 409, 430, and 439. Martensitic stainless steels in grades 410, 420, and 440 are also magnetic. Austenitic steel grades are non-magnetic, such as grades, 3.3, 304, 310, and 321.

Because of its durability and weak magnetic permeability, the grade is often used in cryogenic applications. Applications of Stainless Steel 310 Sheets. Typical applications od SS 310 Plates are found in combustion panels, kilns, radiant tubes, petroleum refining tank hangers and steam boilers.

310 stainless steel grade, which is also know as 1.4845 or 310s is a stainless grade which is commonly used in very high temperature envireoments. This grade is written as 1.4845 or X8CrNi25-21 according to EN norm and it is written as UNS S31008 according to UNS norm.

314 stainless steel is an austenitic, heat resistant grade that is very similar to type 310S. The difference is that 314 has a higher level of silicon, which improves oxidation resistance at elevated temperatures. Alloy 314 has the best high-temperature resistance capabilities of any chromium nickel stainless grades.

Type 310S Stainless Steel is identical to Type 310 except for a lower carbon content that minimizes carbide precipitation and improves weldability. They are essentially nonmagnetic as annealed and become lightly magnetic when cold worked.

Compared to 316L, 310S has better corrosion-resistance in the salt, since it contains more Cr and Ni element. The corrosion layer thickness of the 310S and 316L is 1.613μm and 2.903μm based on the cross-section micrographs, which is equal to 0.499μm/year and 1.460μm/year, respectively.

Corrosion Resistance The alloy is prone to intergranular corrosion after long term exposure at high temperatures. However, due to its high chromium content (25%), Alloy 310 is more corrosion resistant than most heat resistant alloys.