310S SS plate

Stainless Steel Grade 310 is a medium carbon austenitic stainless steel

310S Stainless Steel has excellent resistance to oxidation under constant temperatures to 2000°F.

Alloy 310S, like 309S, is best known for high temperature service. Both alloys work well up to 2000 °F, especially if oxidation resistance is required. 309 and 310S are the premier high temperature performers among the common stainless grades available from our stock. High nickel and chromium content and a coarse grain structure result in:

310S stainless steel provides superior corrosion resistance properties against carburization, oxidation and other conditions. It is fabricated to offer excellent performance in the elevated temperature conditions on the industrial level that need high resistance to carburization and thermal cycling corrosion. It shows austenitic nature in the whole temperatures and doesn’t show embrittlement.The excellent strength and resistance to high temperature oxidation properties are purposeful in the commercial incinerators, kilns and food processing equipments.

310S stainless steel is a low-carbon version of 310 stainless steel, specifically designed for high-temperature applications. Its superior resistance to oxidation, corrosion, and high temperatures makes it an ideal material for extreme conditions in industrial environments.

310S stainless steel is an austenitic stainless steel containing high levels of chromium and nickel. Its composition provides exceptional resistance to oxidation and high temperatures while maintaining good mechanical strength.

310S stainless steel is a versatile material offering high-temperature resistance, oxidation protection, and mechanical strength in extreme conditions. Its long service life and resistance to scaling and corrosion make it indispensable in industries such as chemical processing, power generation, and furnace construction.

310 plate contains no more than 0.25% carbon while 310S contains at most 0.08% carbon. 310H stainless steel is comprised of between 0.04% and 0.1% carbon. 310, 310S and 310H stainless steel plate all contain 2.0% manganese, 0.045% phosphorous and 0.30% sulfur.

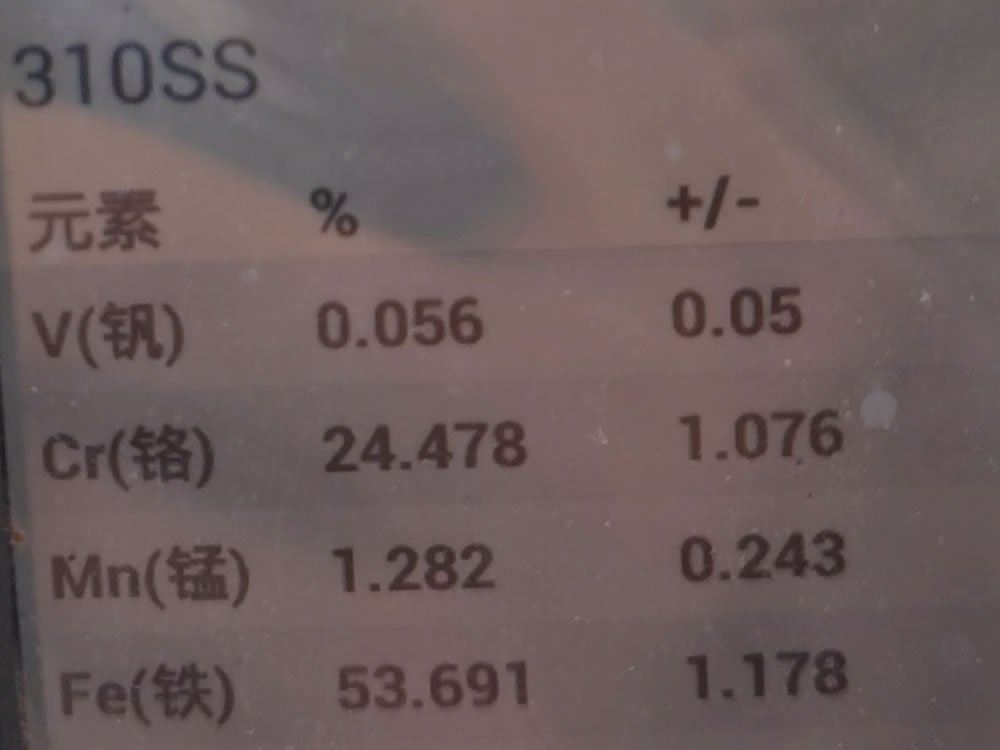

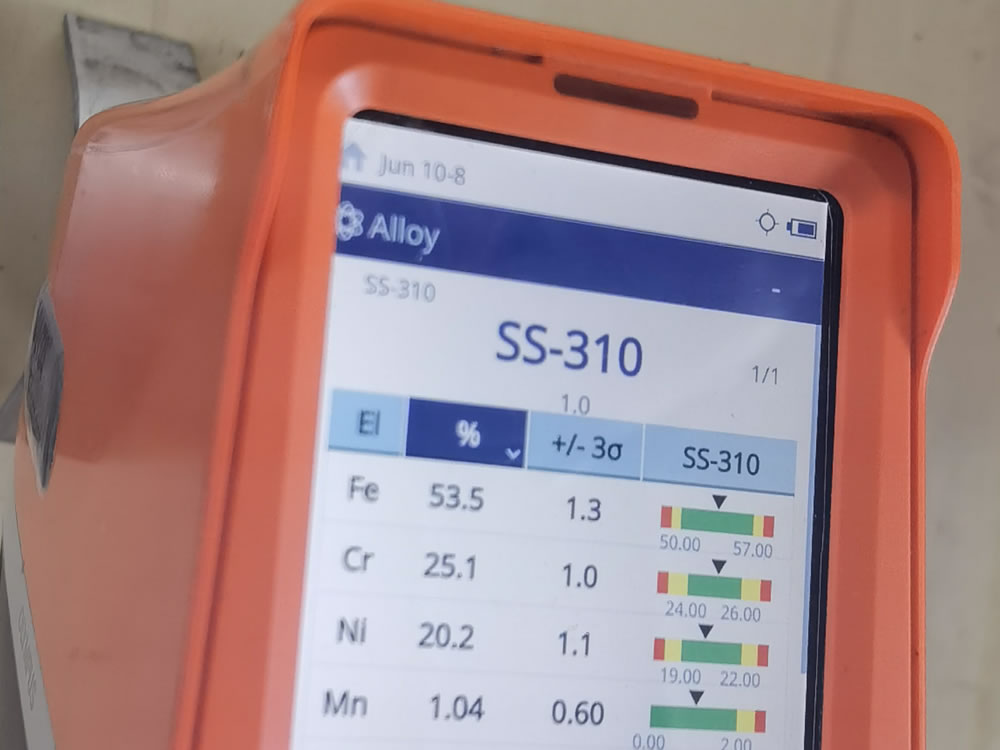

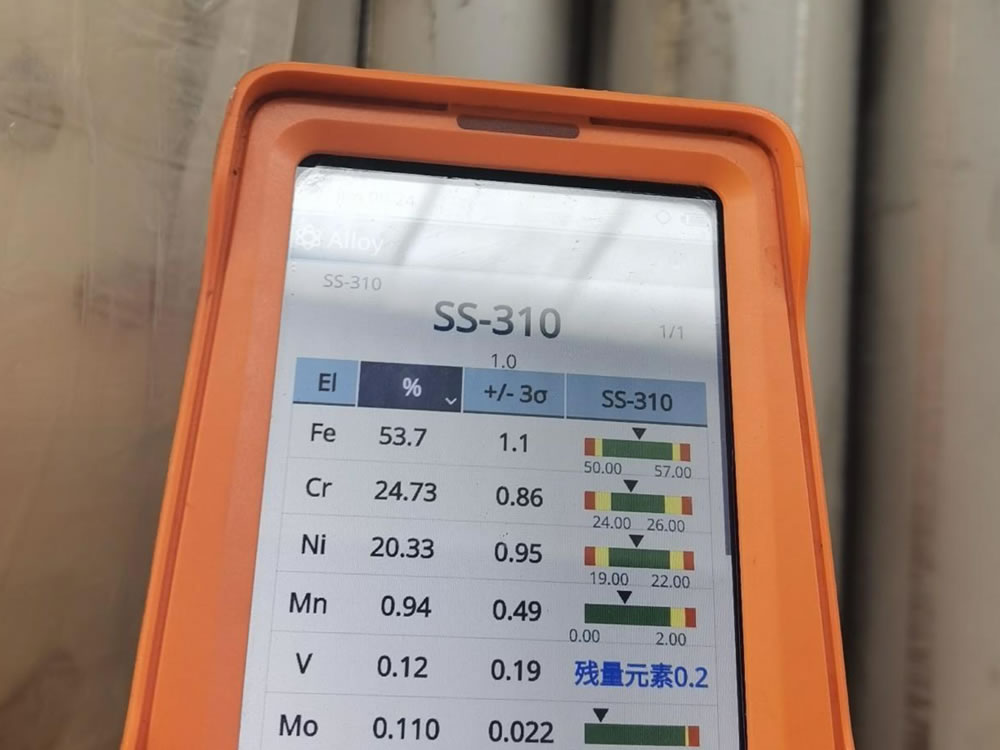

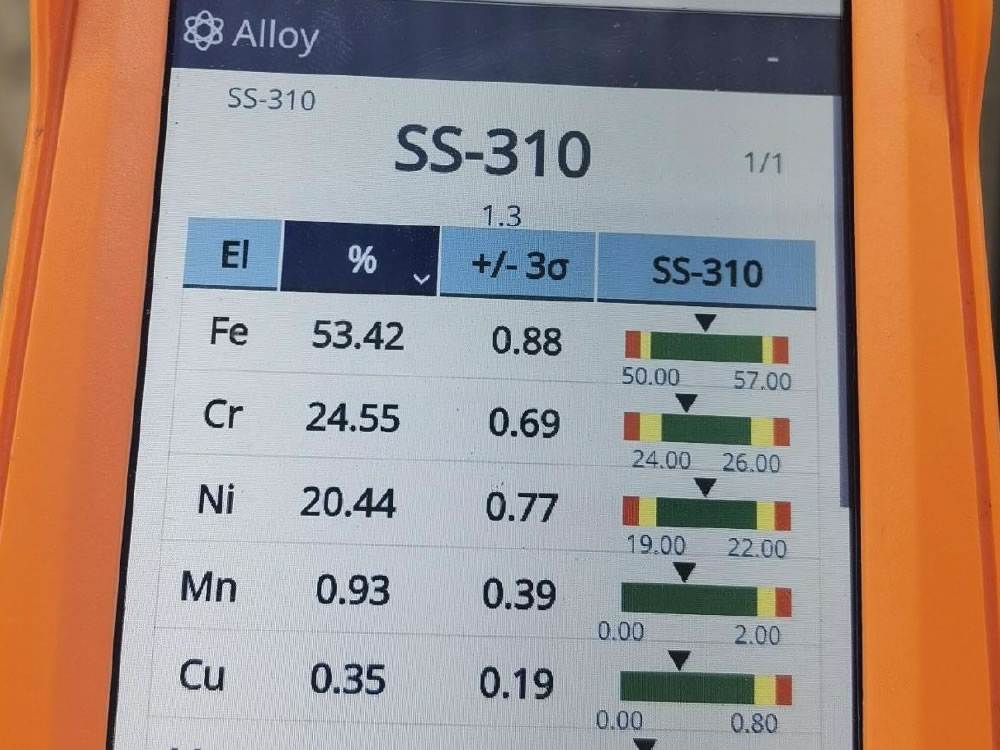

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Fe |

|---|---|---|---|---|---|---|---|---|---|

| SS 310 | 0.015 max | 2.0 max | 0.15 max | 0.020 max | 0.015 max | 24.00 – 26.00 | 0.10 max | 19.00 – 21.00 | 54.7 min |

| SS 310S | 0.08 max | 2.0 max | 1.00 max | 0.045 max | 0.030 max | 24.00 – 26.00 | 0.75 max | 19.00 – 21.00 | 53.095 min |

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

|---|---|---|---|---|---|---|---|

| SS 310 | 1.4841 | S31000 | SUS 310 | 310S24 | 20Ch25N20S2 | - | X15CrNi25-20 |

| SS 310S | 1.4845 | S31008 | SUS 310S | 310S16 | 20Ch23N18 | - | X8CrNi25-21 |

| Item | UNS | ASTM | ASME | AMS |

|---|---|---|---|---|

| 310 | UNS S31000 | ASTM A240 | ASME SA240 | AMS 5521 |

| 310S | UNS S31008 | ASTM A240 | ASME SA240 | AMS 5521 |

| 310H | UNS S31009 | ASTM A240 | ASME SA240 | AMS 5521 |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|

| 7.9 g/cm3 | 1402 °C (2555 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 0.4 |

Alloy 310 can be easily welded and processed by standard shop fabrication practices.

Alloy 310 and 310S stainless steel fittings, flanges and pipes are used in the environmental, chemical processing and refining industries. Some examples of equipment composed of 310 stainless steel include incinerators, furnaces, burners, kilns, annealing and carburizing boxes, combustion chambers, salt pots, thermo wells, gas turbines, retorts, flairs and equipment to handle sulfite liquors.

Cyclic conditions reduce its oxidation resistance, and a maximum operating temperature of 1900°F is generally recommended if cycling is involved.

Having a lower coefficient of expansion than most 300 stainless steels, 310S may be used in operations involving moderately severe thermal cycling, such as rapid air cooling. It is not usually recommended for liquid quenching. Although 310S has less resistance to absorption of carbon and nitrogen than the higher alloys such as 330 and 333, it is widely used in moderately carburizing atmospheres such as encountered in petro-chem plants.

Because of ts high chromium and medium nickel contents, 310S may be used in atmospheres containng moderate amounts of sulfur.

310S grade is a steel comprising of low concentration of carbon. Stainless steel 310S alloy is made of 25% chromium and 20% nickel that make it widely resistant to oxidation and corrosion. The nominal carbon magnitude makes it less inclined to embrittlement and sensitization while in use.

310 plate contains no more than 0.25% carbon while 310S contains at most 0.08% carbon. 310H stainless steel is comprised of between 0.04% and 0.1% carbon. 310, 310S and 310H stainless steel plate all contain 2.0% manganese, 0.045% phosphorous and 0.30% sulfur.

While 304 is flexible and profitable with excellent corrosion resistance, 310/S shines in high-temperature applications with dominating oxidation resistance. Considering the application, environmental conditions, and cost-effectiveness decide the most acceptable stainless-steel grade for your project.

Type 310 has good sulfidation resistance and good resistance to carburization in moderately carburizing atmospheres.

310S (UNS S31008) is the low carbon version of the alloy. It is utilized for ease of fabrication. 310H (UNS S31009) is a high carbon modification developed for enhanced creep resistance. In most instances the grain size and carbon content of the plate can meet both the 310S and 310H requirements.

310 has a machinability rating of 42% relative to AISI B1112 steel. When using high speed steel tooling, this equates to about 70 surface feet per minute. Forming operations should be performed at room temperature whenever possible. Welding with AWS E310-15 electrodes or ER310 bare wire is suggested.

SS 310: Designed for high-temperature applications, offering excellent strength and oxidation resistance at elevated temperatures. SS 316: While suitable for moderate temperatures, SS 316 may experience reduced corrosion resistance compared to SS 310 in high-temperature environments.

If it has an austenite structure, then it will not be magnetic. In other words, ferritic grades of stainless steel are magnetic, such as grades 409, 430, and 439. Martensitic stainless steels in grades 410, 420, and 440 are also magnetic. Austenitic steel grades are non-magnetic, such as grades, 3.3, 304, 310, and 321.

Because of its durability and weak magnetic permeability, the grade is often used in cryogenic applications. Applications of Stainless Steel 310 Sheets. Typical applications od SS 310 Plates are found in combustion panels, kilns, radiant tubes, petroleum refining tank hangers and steam boilers.

310 stainless steel grade, which is also know as 1.4845 or 310s is a stainless grade which is commonly used in very high temperature envireoments. This grade is written as 1.4845 or X8CrNi25-21 according to EN norm and it is written as UNS S31008 according to UNS norm.

314 stainless steel is an austenitic, heat resistant grade that is very similar to type 310S. The difference is that 314 has a higher level of silicon, which improves oxidation resistance at elevated temperatures. Alloy 314 has the best high-temperature resistance capabilities of any chromium nickel stainless grades.

Type 310S Stainless Steel is identical to Type 310 except for a lower carbon content that minimizes carbide precipitation and improves weldability. They are essentially nonmagnetic as annealed and become lightly magnetic when cold worked.

Compared to 316L, 310S has better corrosion-resistance in the salt, since it contains more Cr and Ni element. The corrosion layer thickness of the 310S and 316L is 1.613μm and 2.903μm based on the cross-section micrographs, which is equal to 0.499μm/year and 1.460μm/year, respectively.

Corrosion Resistance The alloy is prone to intergranular corrosion after long term exposure at high temperatures. However, due to its high chromium content (25%), Alloy 310 is more corrosion resistant than most heat resistant alloys.