High strength low alloy rare earth wear-resistant steel is a type of steel that is specifically designed to have high strength, low alloy content, and enhanced wear resistance.

Download PDFHigh-strength rare earth wear-resistant alloy is a new type of rare earth alloy material, containing Cr, Ni, V, Mo, Mn, W, Cu and other alloying elements.

High-strength, low-alloy, rare earth wear-resistant steel not only has high hardness, but also has certain mechanical properties, good welding performance at room temperature, and has the possibility of stability and field opening, and also has certain corrosion resistance. Compared with high manganese steel material under the same conditions, its unit wear is about 1/5 of high manganese steel, and its service life is 4-5 times that of high manganese steel. Compared with polyurethane wear resistant pipe, rare earth alloy wear resistant pipe Cuttable and weldable. Elbow and branch pipes can be used together with seamless pipe sections, making installation and maintenance more convenient, strength, low-alloy, rare.

Rare earth wear-resistant alloy pipes are used in parts with severe wear, such as elbows, reducers, suction ports, etc., which can be cast as a whole, and then machined, especially in the parts where the outer side of the elbow is particularly worn. , The outer diameter is designed with a more central method, so that the parts with severe wear can be locally thickened, and according to various requirements, irregular types of pipe fittings can be produced to meet the design requirements. The straight pipe is formed by centrifugal casting, without air. Shrinkage cavities, slag inclusions and other casting defects. In the actual use process, good results have been achieved in the use of water slag pipelines in steel plants and coal washing pipelines in coal preparation plants.

Abrasive wear is the most serious form of wear among all kinds of wear, and its essence is the result of the cutting or chiseling effect of hard abrasive particles on the metal surface. The abrasive particles penetrate into the metal surface to produce plastic deformation and wear scars until the metal surface is abraded. The new high-strength rare earth wear-resistant material is developed based on this principle.

Rare earth alloy wear-resistant pipe is used for pneumatic, pumping slurry and other material conveying pipes. It has the characteristics of fast flow rate and large flow rate.

Compared with high manganese steel materials under the same conditions, the unit wear of rare earth alloy is about 1/3 that of high manganese steel, and its service life is 2-3 times that of high manganese steel.

Because R alpha composition and structure characteristics of carbide , and the content of solid solution to Cr matrix has strong heat resistance, corrosion resistance, and add the Mo in the high temperature or corrosive environment shows the performance of corrosion resistance, abrasion resistance, add a certain amount of rare earths, giving the inner structure of the alloy is more compact, surface to form a layer of protective film, prevent seepage of carbon. Increased wear resistance, corrosion resistance; Containing a certain amount of boron makes the alloy hardness , which can not was achieved by carburizing. At the same time, containing a certain amount of Mn increases the fatigue resistance of the alloy , so that the wear resistance of the alloy is better than that of high chromium alloy and rare earth alloy.

Alloy wear-resistant casting pipe can bear the pressure of 6 ㎏ / cm2, can be applied to gas conveying high pressure pipeline, for external use high-quality steel pipe or is made of high qualified steel plate, hot pressing push system, through the good welding, makes the elbow in more than 10 kg/cm2 pressure is no problem, won’t appear because of local air leakage, diversion phenomenon of material.

Such as bimetallic materials can not be manufactured in the power plant coal grinding, pulverizing, ash removal, slag discharge system of some equipment accessories. Such as dredge scraper, pulverized coal mixer, spiral tube, etc., can be made of this material, which brings great convenience to power plant operation, maintenance and management.

On the basis of centrifugal casting and resin sand molding, the company introduced a new EPC lost foam vacuum suction casting process to make molds according to product structure, application, usage method and quantity, with high dimensional accuracy, uniform material organization and stable performance, especially for wear-resistant Spiral pipes, pulverized coal mixers, fork pipes, import and export hoppers, round and round joints, cone buckets and other special-shaped parts are cast as a whole, and the wall thickness is uniform.

The disadvantage of rare earth wear-resistant alloy steel is its low impact resistance, so it should be carefully handled during transportation and installation.

The use of anti-off porcelain tube, porcelain tube mosaic, so that paste more flat, more solid with a strong inorganic adhesive paste, wear-resistant steel bowl welding, porcelain and steel body combined to form a double reinforcement to ensure that the porcelain tube does not fall off.

The installation of flexible, high wear resistance, processing convenience, the cost is moderate.

Rockwell hardness of high alumina ceramics is up to HRA80-90 which is second only to diamond and far exceeds wear-resistant steel stainless

The wear resistance of high alumina ceramics is 266 times that of manganese steel and 171.5 times that of high chromium cast iron. According to our investigation & follow-up to the clients, the service life of equipment can be prolonged over 10 times under the same working conditions.

Working temperature of high alumina ceramics can be as high as 1400℃.

High alumina ceramics have the properties of self-lubricity and in adhesion, the roughness is only 1/6 that of steel pipes thus less flow Resistance.

Thick-walled and shaped seamless steel tubes are our advantage products which can be customized according to customers' needs

The density of high alumina ceramics is about 3.6g/cm3, which is only half that of steel, thus easy for construction and installation.

The addition of these alloying elements gives ZG40CrMnMoNiSiRe improved strength, toughness, and corrosion resistance compared to standard carbon steels. It also has good weldability and can be easily machined into different shapes and sizes.

ZG40CrMnMoNiSiRe is designed to operate in extreme conditions, such as high temperatures and pressures, making it suitable for use in boiler tubes, heat exchangers, and other high-temperature applications. It is also resistant to corrosion and creep, which makes it ideal for use in harsh environments.

Overall, ZG40CrMnMoNiSiRe is a specialized steel grade that offers many benefits for high-temperature and high-pressure applications, but may not be suitable for all applications due to its specific alloying elements and properties.

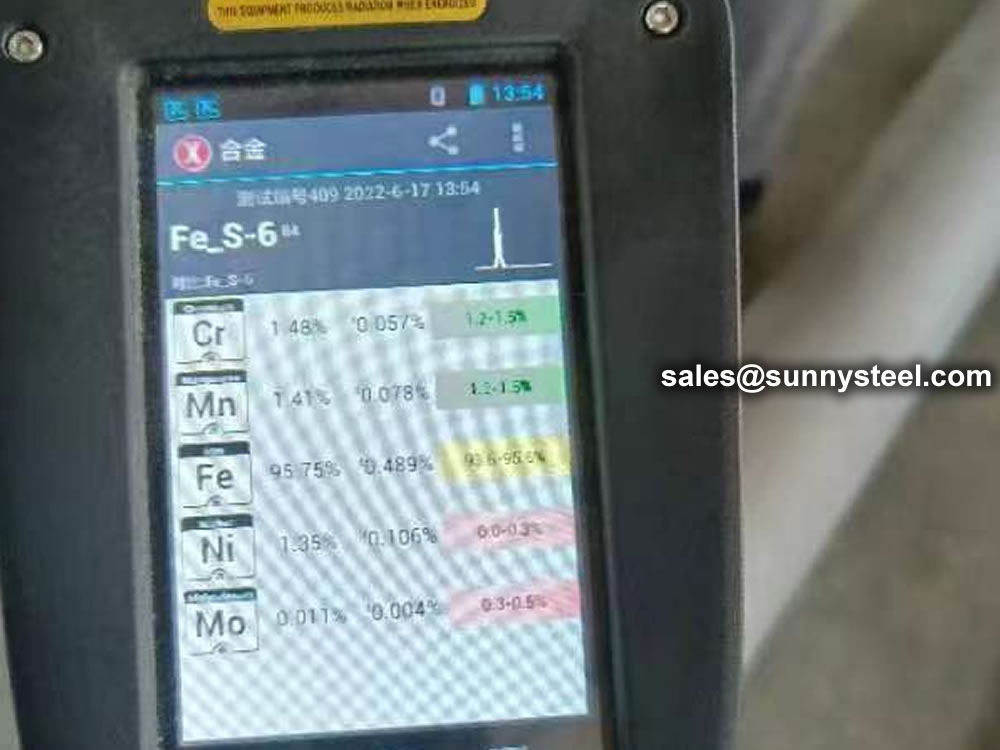

| Grade | C | Cr | Mn | Mo | Ni | Si | S | P | Re |

|---|---|---|---|---|---|---|---|---|---|

| ZG40CrMnMONiRe (JM6a) | 0.35-0.42 | 1-1.14 | 1-1.14 | 0.3-0.6 | 0.5-0.8 | 0.8-1.2 | ≤0.04 | ≤0.04 | ≤0.02 |

The composition, design of medium carbon alloy, rare earth wear-resistant steel adopts medium carbon multi-alloy system to ensure that the material maintains comprehensive performance indicators. Combining the characteristics of our country's resources, this material adopts a small amount of multi-element alloy body, and adds FeV, FeNb, Cu and other multi-alloy elements on the basis of the original alloy materials FeCr, FeMn, Ni, Re, FeSi, etc., to ensure the performance of the product.

The mechanical properties adopt perfect testing methods to ensure the stability of material properties.

| Grade | Tensile strength σb MPa | Impact ak j/cm2 | Hardness HRC |

|---|---|---|---|

| ZG40CrMnMoNiRe(JM6a) | ≥860 | 30 | ≥40 |

The wear and tear of rare earth alloy is a phenomenon of material loss caused by relative motion between objects.

Rare earth wear-resistant alloy steels / steeled tube wear-resistant materials can resist wear and prolong the life of the product. Mainly divided into single metal pipe and composite pipe. According to the shape can be divided into straight pipe, elbow, tee, four-pass, reducer, Fangyuan section and other special-shaped tubes. Surface Quality requirements : the internal and external surface of the pipeline should be smooth and smooth, no burrs, burrs, sticky sand, more meat or lack of meat, no cracks, loose, stomata or bubbles. Rare earth wear-resistant pipe, is in the area of serious wear, such as elbow, reducer, suction nozzle, such as the use of the model as a whole casting, especially in the outside of the elbow wear particularly significant parts, the external diameter of the method to change the center of the design, so that the wear serious parts of the local thickening, but also according to various requirements, Make a variety of irregular shaped pipe fittings to meet the design requirements, straight pipe is centrifugal casting. Second, the rare earth wear-resistant alloy containing CR, Ni, Mo, W, V, Cu and many other alloy elements, it not only has a high hardness, but also has a certain mechanical properties, at room temperature with good welding performance, and has the possibility of cutting and on-site openings, but also has a certain corrosion resistance. In the actual use of the process, whether it is in the steel slag pipe, or in the coal preparation plant, such as the use of washing pipes have achieved very good results, in the same conditions compared with high manganese steel, the unit wear is about 1/5 of the higher manganese steel, the service life is high manganese steel 4-5 times, elbow and branch pipe can be used with seamless pipe fittings, installation, maintenance more convenient. High strength and low alloy rare earth heat-resisting and wear-resisting steel pipe parts are suitable for coal conveying, powder feeding, ash discharging pipeline and coal preparation plant transportation pipeline in thermal power plant boiler system.

ZG40Cr8MnMoNiSiRe is the latest rare earth alloy wear-resistant material developed by our factory on the basis of the original rare earth alloy. By increasing the content of Cr in the rare earth alloy, the wear resistance of the rare earth alloy is greatly increased. ZG40Cr8MnMoNiSiRe now is instead of ZG40CrMnMoNiSiRe to produce rare earth metal wear resistant pipe and fittings.

ZG40Cr8MnMoNiSiRe is a type of high-strength low-alloy steel (HSLA) that is commonly used in the manufacturing of heavy machinery and equipment components.

According to Sunny Steel, including ZG40Cr8MnMoNiSiRe, are designed to provide improved mechanical properties and greater resistance to corrosion and wear compared to traditional carbon steels.

The chemical composition of ZG40Cr8MnMoNiSiRe includes chromium (Cr), manganese (Mn), molybdenum (Mo), nickel (Ni), silicon (Si), and rare earth elements such as cerium (Ce) and dysprosium (Dy). The specific amounts of each element are controlled within certain limits to ensure consistent mechanical properties.

ZG40Cr8MnMoNiSiRe is often used in applications that require high strength and toughness, such as heavy-duty construction equipment, mining machinery, and power generation equipment. The alloy's excellent wear and corrosion resistance also make it suitable for use in harsh environments, such as those encountered in offshore drilling and marine applications.

| No. | Grade | C | Mn | Si | Cr | Ni | Mo | W | V | Nb | Cu | Re | N | S | P |

| 1 | ZGCr20Mo3Ni3Re | 2.50/3 | 1.50/2 | 0.80/1.2 | 18.0/23 | 2.50/3 | √ | 1.20/1.5 | √ | ≤0.06 | ≤0.06 | ||||

| 2 | ZGCr28Mo3Ni3Re | 2.80/3.3 | 1.50/2 | 1.80/1.2 | 25.0/300 | 2.80/3.3 | √ | 1.80/2.3 | √ | ≤0.06 | ≤0.06 | ||||

| 3 | ZGCr15Mo3Re | 2.60/3.2 | 1.20/1.6 | 1.0/1.5 | 12.0/16 | √ | 2.50/3 | 1080/1.2 | √ | ≤0.04 | ≤0.05 | ||||

| 4 | ZGCr25Ni4Si2Re | 0.35/0.45 | 0.80/1.2 | 1.20/1.6 | 23.0/26 | 3.50/4.5 | √ | √ | ≤0.035 | ≤0.045 | |||||

| 5 | ZGCr15Mo2Re | 1.80/2.2 | 0.80/1.2 | 1.0/1.5 | 14.0/18 | √ | 2.0/2.5 | 0.80/1.2 | √ | ≤0.04 | ≤0.05 | ||||

| 6 | ZG40CrMnMoNiSiRe | 0.40/0.5 | 1.20/1.6 | 1.50/2 | 1.10/1.6 | 1.0/1.5 | √ | √ | √ | √ | ≤0.035 | ≤0.04 | |||

| 7 | ZG40Cr5Ni3MoVWRe | 0.35/0.45 | 0.80/1.2 | 1.20/1.6 | 23.0/26 | 2.50/3.5 | √ | √ | √ | √ | ≤0.045 | ≤0.055 | |||

| 8 | ZG50Cr18Ni4MoVWCuRe | 0.45/0.6 | 1.0/1.4 | 1.50/2 | 16.0/20 | 3.50/5 | √ | √ | √ | 0.40/0.6 | √ | ≤0.35 | ≤0.35 | ||

| 9 | ZGCr25Ni2Mo2WVCuRe | 0.40/0.6 | 0.80/1.2 | 1.20/1.6 | 23.0/v | 1.50/2.5 | √ | √ | √ | 0.20/0.4 | √ | ≤0.035 | ≤0.035 | ||

| 10 | ZG40Cr25Ni6MoWVCuRe | 0.35/0.45 | 1.2/1.6 | 1.50/2 | 23.0/26 | 5.0/7 | √ | √ | √ | √ | √ | √ | ≤0.35 | ≤0.045 | |

| 11 | ZG90CrMn13MoSiVRe | 0.40/1.3 | 11.0/14 | 0.30/0.8 | √ | √ | ≤0.04 | ≤0.04 | |||||||

| 12 | ZGCrMu10MoSiVRe | 1.0/1.2 | 8.0/11 | 0.30/0.8 | √ | √ | ≤0.04 | ≤0.04 | |||||||

| 13 | ZGW5Cr4Re | 2.50/3.5 | 1.5/1 | 0.50/1 | 35.0/4.5 | √ | √ | ≤0.10 | ≤0.15 | ||||||

| 14 | ZGCr25MoRe | 2.30/3 | 0.50/0.9 | 0.30/0.6 | 23.0/28 | √ | √ | ≤0.06 | ≤0.10 | ||||||

| 15 | ZGCr15MoRe | 3.0/3.5 | ≤1.0 | 0.15/1 | 15.0/18.6 | 2.80/3.3 | √ | ≤0.06 | ≤0.10 | ||||||

| 16 | ZG30CrMnSi | 0.27/0.33 | 1.30/1.5 | 1.20/1.5 | √ | √ | √ | ≤0.03 | ≤0.04 | ||||||

| 17 | ZG40CrNiRe | 0.28/0.43 | 1.10/1.4 | 0.80/1 | √ | √ | √ | ≤0.06 | ≤0.10 | ||||||

| 18 | ZG33Cr13Ni4Re | 0.30/0.35 | ≤0.80 | ≤0.60 | 12.0/14 | 4.0/4.5 | √ | √ | ≤0.06 | ≤0.10 | |||||

| 19 | ZG40CrSiN | 0.35/0.45 | 1.0/1.5 | 1.50/2 | √ | √ | ≤0.04 | ≤0.08 |

Note: All content in this article is for reference only.

| temperature ℃ |

Abrasive wearmg/g | hardness HRC |

Tensile strengthN/mm² | Impact toughness J/cm² |

|---|---|---|---|---|

| ≤300 | 0.021 | ≥63 | 890 | 5 |

| ≤350 | 0.033 | ≥56 | 910 | 6 |

| ≤350 | 0.042 | ≥45 | 910 | 6 |

| ≤400 | 0.069 | ≥42 | 960 | 6 |

| ≤400 | 0.039 | ≥48 | 920 | 7 |

| ≤400 | 0.064 | ≥40 | 950 | 7 |

| ≤400 | 0.069 | ≥36 | 910 | 8 |

| ≤400 | 0.036 | ≥42 | 1040 | 8.5-10 |

Note: All content in this article is for reference only.

No.:ZG40CrNiMoMnSiRe

Hardness:HTC≥40

Rare earth alloy wear-resistant pipe is used for conveying wear-resistant pipes such as power plant powder and ash, mine slag and non-ferrous metal coal extraction and slag discharge, shock resistance and wear resistance.

The application fields of rare earth alloy wear-resistant pipes are as follows:

The rare earth alloy pipes are used for powder conveying and ash discharging in power plants, slag conveying in mines, coal lifting and slag discharging in non-ferrous metals, and impact and wear resistant pipes.

Coal-fired power plant

Coal conveying, ash removal, slag discharge pipes, powder feeding, powder returning pipes, desulfurization pipes, etc.;

Mine

In the coal industry, coal-water slurry, coal washing slime, mine filling material, mine pulverized heavy medium coal washing pipeline, chute, etc.;

Metal Mine

Conveying wear-resistant pipes for concentrates and tailings;

Metallurgy

Blast furnace coal injection and slag conveying pipes in iron and steel plants; CAO, zinc and sand conveying pipes, iron alloy conveying in steel making, out-of-furnace refining and other preferred wear-resistant pipes;

Cement plant

Raw slurry transportation, pulverized coal transportation, hoist unloading, finished cement pneumatic transportation loading and unloading, concrete transportation pipeline of rotary kiln wet production line.

Chemical plant

Coal powder conveying pipeline, silicon powder and other raw material conveying wear-resistant elbows.

The composition design of medium carbon alloy rare earth wear-resistant steel adopts medium carbon multi-alloy system to ensure that the material maintains comprehensive performance indicators. Combining the characteristics of our country’s resources, this material adopts a small amount of multi-element alloy body, and adds FeV, FeNb, Cu and other multi-alloy elements on the basis of the original alloy materials FeCr, FeMn, Ni, Re, FeSi, etc., to ensure the performance of the product.

The medium carbon alloy rare earth wear-resistant steel has high wear resistance, and the rare earth wear-resistant alloy steel has strong wear resistance. After adding FeV, FeNb, and Cu, the metallographic structure of the material has changed. The metallographic structure is: Lath Martensite + Bainite. The grains are finer, the strength is higher, the plasticity is stronger, and the metal matrix is further passivated, so that the wear resistance of the original material has been improved.

Medium carbon alloy rare earth wear-resistant steel has high temperature resistance, strong corrosion resistance and improved wear resistance. The content of Ni and Cr elements in the alloy directly determines the temperature resistance of the material. The content of Cr element and Cu element determines the corrosion resistance of the material. The reasonable combination of these elements makes the new rare earth wear-resistant alloy material have several properties at the same time, such as high wear resistance and high wear resistance. It has excellent corrosion resistance, so it can adapt to the use of various harsh working conditions.

The medium carbon alloy rare earth wear-resistant steel has advanced technology and stable performance. On the basis of centrifugal casting and resin sand molding, our factory has introduced a new EPC lost foam vacuum suction casting process to make molds according to product structure, application, use method, and quantity. High precision, uniform material structure and stable performance, especially for special-shaped parts such as wear-resistant spiral pipes, pulverized coal mixers, fork pipes, import and export hoppers, round and round joints, cone buckets, etc., the wall thickness is uniform.

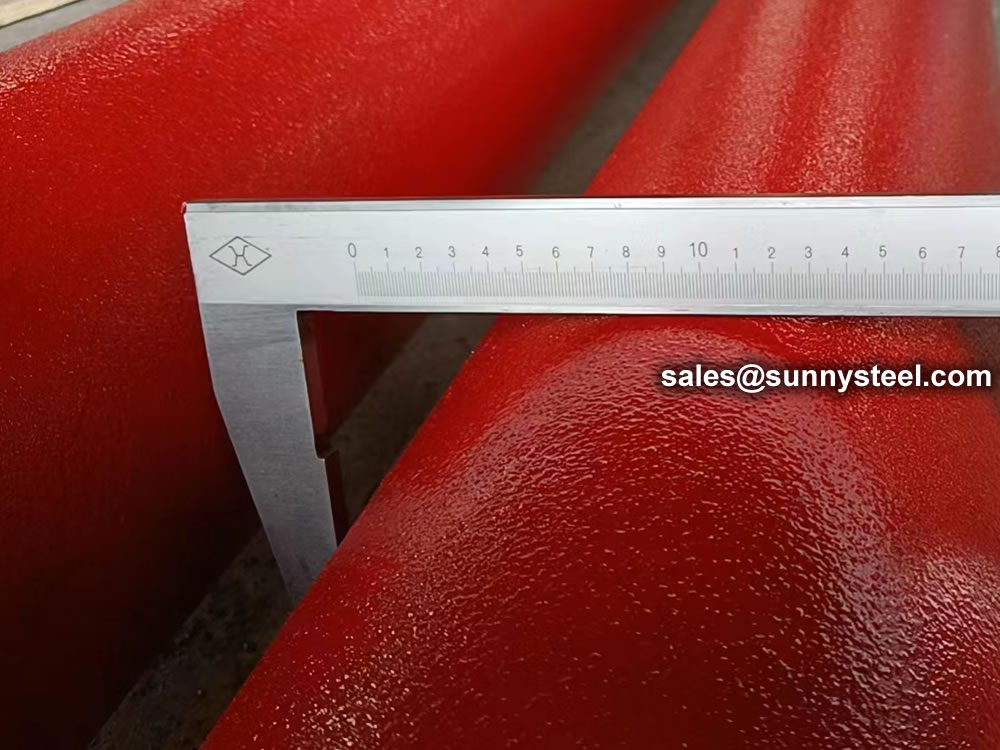

Abrasion resistant pipe using steel skeleton packaging, and the two ends of the pipe with plastic head, to prevent dust and rain into the pipeline inside, to ensure the beauty of the product.

The wear and tear of rare earth alloy is a phenomenon of material loss caused by relative motion between objects.

Rare earth alloy wear-resistant pipe is produced by horizontal centrifugal casting, in which the smelted liquid metal is passed through the pouring riser and diverted into the rotating mold barrel (the speed of the mold barrel is generally 800-1000 rpm), under the action of centrifugal force A casting method for filling and solidifying into a casting. The horizontal centrifugal casting machine is used for casting various tubular castings and various carbon steel, alloy steel pipes and double-layer steel rolls that require different compositions of inner and outer layers.

Liquid metal can form a hollow cylindrical free surface in a mold without a core. In the production process, the casting process is greatly simplified, with high productivity and low cost. Under the action of centrifugal force, the metal liquid improves the ability of metal to fill the mold, so some alloys and thin-walled castings with poor fluidity can be produced by centrifugal casting.

Due to the centrifugal force, casting defects are improved, shrinkage holes (shrinkage porosity), pores, inclusions and other defects are reduced, and the mechanical properties are improved. Because centrifugal casting has no riser runway, etc., the utilization rate of metal is improved.

Rare earth wear-resistant alloy pipe material has strong anti-wear performance, so when choosing rare earth alloy wear-resistant pipe, higher wear resistance is required, how to improve it?