The rare earth alloy wear- esistant pipe is used for pneumatic, pump slurry, etc. Rare earth alloy wear resistant pipe has the characteristics of fast velocity and high flow rate.

Download PDFThe conveying medium temporarily continues to produce impact on the pipe wall, wear, corrosion and so on, which causes the pipe to become tired and gradually wear out. Rare earth alloy wear-resistant pulverized coal mixer is one of the equipment arranged on the pulverized coal wear-resistant pipeline of coal-fired boilers, and is used in the coal conveying system of intermediate storage coal-fired boilers. It is an important equipment in the blast furnace coal injection system to transport the pulverized coal in the injection tank to the blast furnace, and is used for uniform mixing of the pulverized coal and the compressed air.

Rare earth alloy wear-resistant high chromium cast iron pipe under the same conditions as compared with the high manganese steel materials, the unit is a high-manganese steel wear about 1/3, life is more than three times as high manganese steel. Bends and branches seamless steel pipe segment with supporting the use, manufacture applicable irregular pipelines, cutting, welding easy maintenance.

Excellent welding performance, with cuttability and the possibility of on-site drilling.This process can avoid pores, slag inclusion, loose assembly and large deformation. and other common casting defects, the material composition is based on the original FeCr, FeMn, Ni, Re, FeSi and other alloy materials, and ferrovanadium (FeV), ferroniobium (FeNb), copper (Cu) are added, so that the material has both high alloy The wear resistance of casting has high mechanical strength and impact resistance, and at the same time improves the weldability of the material. Rare earth alloy wear-resistant elbows are used in coal grinding systems, pulverizing systems, slag and ash removal systems, heavy medium coal washing systems, and slag transportation pipelines in metallurgical systems.

Abrasive wear is a serious form of wear among all kinds of wear, and its essence is the result of the cutting or chiseling action of hard abrasive particles on the metal surface. The abrasive particles penetrate the metal surface to produce plastic deformation and wear scars until the metal surface is abraded. The new high strength low alloy rare earth wear resistant steel pipe is developed according to this principle, and the components are various alloying elements such as Cr, Ni, V, Mo, W, and Cu.

The material of Rare earth alloy coal mill spiral tube contains various alloy elements such as Cr, Ni, Mo, W, V, Cu, etc. It not only has high hardness, corrosion resistance, certain mechanical properties, but also has good performance at room temperature. excellent welding performance, with cuttability and the possibility of on-site drilling.This process can avoid pores, slag inclusion, loose assembly and large deformation. and other common casting defects, the material composition is based on the original FeCr, FeMn, Ni, Re, FeSi and other alloy materials, and ferrovanadium (FeV), ferroniobium (FeNb), copper (Cu) are added, so that the material has both high alloy The wear resistance of casting has high mechanical strength and impact resistance, and at the same time improves the weldability of the material. Rare earth alloy wear-resistant elbows are used in coal grinding systems, pulverizing systems, slag and ash removal systems, heavy medium coal washing systems, and slag transportation pipelines in metallurgical systems.

Rare earth alloy wear – resistant tube is badly worn parts, such as pipe, elbow, reducer, and water intake place such as the model of integral casting, then mechanical processing method, especially the outer wear parts, especially in the elbow to the outer diameter change circle method is adopted to carry on the design, local thickening severe wear parts, but also according to various requirements, produce all kinds of irregular switch pipe fittings to meet the design requirements, straight tube is using centrifugal casting.Rare-earth wear-resistant alloy containing Cr, Ni, V, Mo, W, a variety of alloy element such as Cu, it not only has high hardness, but also has certain mechanical properties, at room temperature with good welding performance, and can be cut and the possibility of opening, also has certain corrosion resistance.

Rare earth alloy wear-resistant pipe is used for conveying wear-resistant pipes such as power plant powder and ash, mine slag and non-ferrous metal coal extraction and slag discharge, shock resistance and wear resistance.

The application fields of rare earth alloy wear-resistant pipes are as follows:

The rare earth alloy pipes are used for powder conveying and ash discharging in power plants, slag conveying in mines, coal lifting and slag discharging in non-ferrous metals, and impact and wear resistant pipes.

Coal-fired power plant

Coal conveying, ash removal, slag discharge pipes, powder feeding, powder returning pipes, desulfurization pipes, etc.;

Mine

In the coal industry, coal-water slurry, coal washing slime, mine filling material, mine pulverized heavy medium coal washing pipeline, chute, etc.;

Metal Mine

Conveying wear-resistant pipes for concentrates and tailings;

Metallurgy

Blast furnace coal injection and slag conveying pipes in iron and steel plants; CAO, zinc and sand conveying pipes, iron alloy conveying in steel making, out-of-furnace refining and other preferred wear-resistant pipes;

Cement plant

Raw slurry transportation, pulverized coal transportation, hoist unloading, finished cement pneumatic transportation loading and unloading, concrete transportation pipeline of rotary kiln wet production line.

Chemical plant

Coal powder conveying pipeline, silicon powder and other raw material conveying wear-resistant elbows.

The composition design of medium carbon alloy rare earth wear-resistant steel adopts medium carbon multi-alloy system to ensure that the material maintains comprehensive performance indicators. Combining the characteristics of our country’s resources, this material adopts a small amount of multi-element alloy body, and adds FeV, FeNb, Cu and other multi-alloy elements on the basis of the original alloy materials FeCr, FeMn, Ni, Re, FeSi, etc., to ensure the performance of the product.

The medium carbon alloy rare earth wear-resistant steel has high wear resistance, and the rare earth wear-resistant alloy steel has strong wear resistance. After adding FeV, FeNb, and Cu, the metallographic structure of the material has changed. The metallographic structure is: Lath Martensite + Bainite. The grains are finer, the strength is higher, the plasticity is stronger, and the metal matrix is further passivated, so that the wear resistance of the original material has been improved.

Medium carbon alloy rare earth wear-resistant steel has high temperature resistance, strong corrosion resistance and improved wear resistance. The content of Ni and Cr elements in the alloy directly determines the temperature resistance of the material. The content of Cr element and Cu element determines the corrosion resistance of the material. The reasonable combination of these elements makes the new rare earth wear-resistant alloy material have several properties at the same time, such as high wear resistance and high wear resistance. It has excellent corrosion resistance, so it can adapt to the use of various harsh working conditions.

The medium carbon alloy rare earth wear-resistant steel has advanced technology and stable performance. On the basis of centrifugal casting and resin sand molding, our factory has introduced a new EPC lost foam vacuum suction casting process to make molds according to product structure, application, use method, and quantity. High precision, uniform material structure and stable performance, especially for special-shaped parts such as wear-resistant spiral pipes, pulverized coal mixers, fork pipes, import and export hoppers, round and round joints, cone buckets, etc., the wall thickness is uniform.

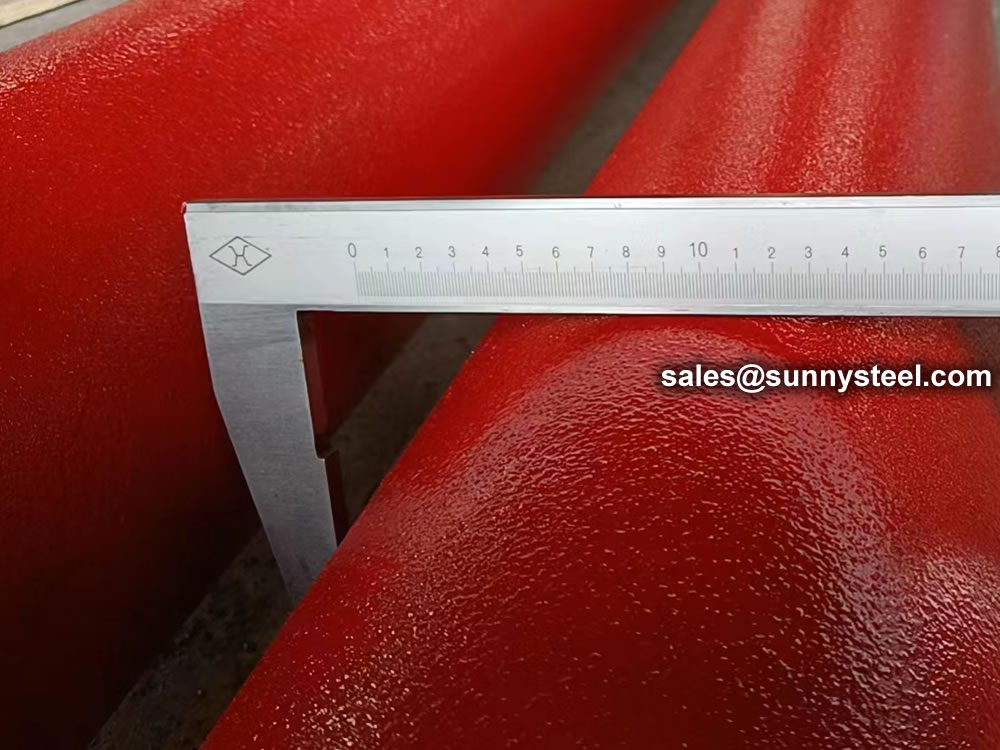

Abrasion resistant pipe using steel skeleton packaging, and the two ends of the pipe with plastic head, to prevent dust and rain into the pipeline inside, to ensure the beauty of the product.

The wear and tear of rare earth alloy is a phenomenon of material loss caused by relative motion between objects.

Rare earth alloy wear-resistant pipe is produced by horizontal centrifugal casting, in which the smelted liquid metal is passed through the pouring riser and diverted into the rotating mold barrel (the speed of the mold barrel is generally 800-1000 rpm), under the action of centrifugal force A casting method for filling and solidifying into a casting. The horizontal centrifugal casting machine is used for casting various tubular castings and various carbon steel, alloy steel pipes and double-layer steel rolls that require different compositions of inner and outer layers.

Liquid metal can form a hollow cylindrical free surface in a mold without a core. In the production process, the casting process is greatly simplified, with high productivity and low cost. Under the action of centrifugal force, the metal liquid improves the ability of metal to fill the mold, so some alloys and thin-walled castings with poor fluidity can be produced by centrifugal casting.

Due to the centrifugal force, casting defects are improved, shrinkage holes (shrinkage porosity), pores, inclusions and other defects are reduced, and the mechanical properties are improved. Because centrifugal casting has no riser runway, etc., the utilization rate of metal is improved.

Rare earth wear-resistant alloy pipe material has strong anti-wear performance, so when choosing rare earth alloy wear-resistant pipe, higher wear resistance is required, how to improve it?