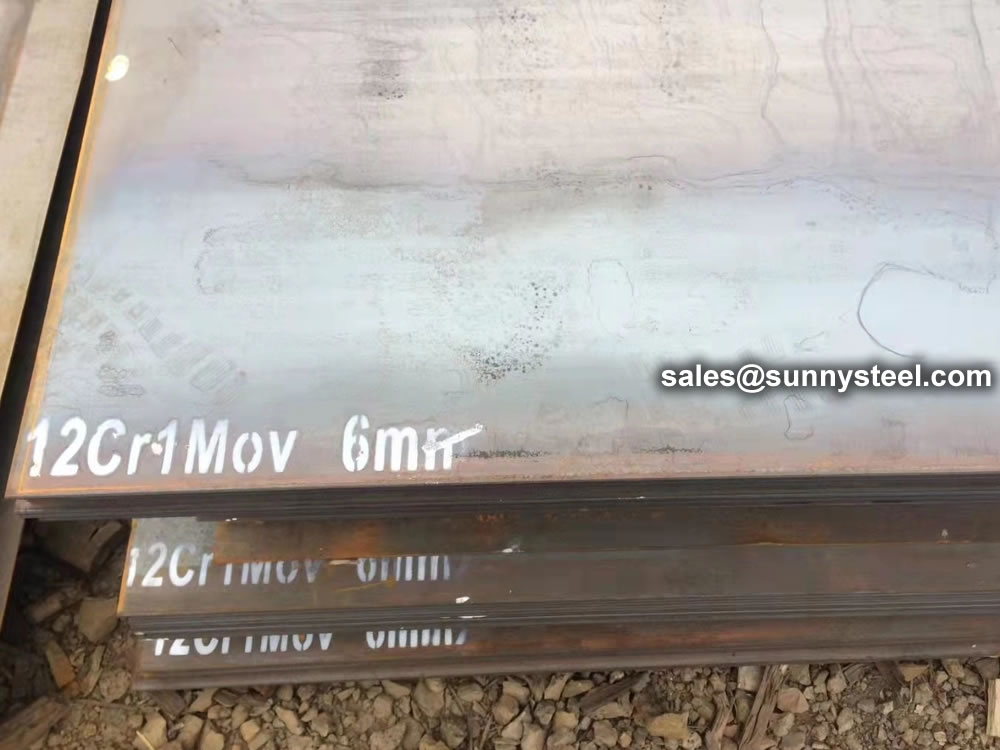

12Cr1MoV Steel Plate has a high thermal strength and anti-oxidant properties, have higher durable plastic.

12Cr1MoV steel is a low-alloy steel known for its excellent high-temperature strength, corrosion resistance, and ability to withstand high pressure. Due to these properties, it is widely used in industries like power generation, petrochemicals, and boilers. This article explores the key features, applications, and benefits of 12Cr1MoV steel plates.

12Cr1MoV is a low-alloy steel that contains chromium (Cr), molybdenum (Mo), and vanadium (V), elements that enhance its mechanical properties. The main characteristics of 12Cr1MoV steel include:

12Cr1MoV steel plates offer an excellent combination of high-temperature strength, corrosion resistance, and durability, making them indispensable in industries such as power generation, petrochemicals, and boiler manufacturing. Their ability to withstand extreme conditions while maintaining structural integrity ensures safe, reliable performance in demanding environments.

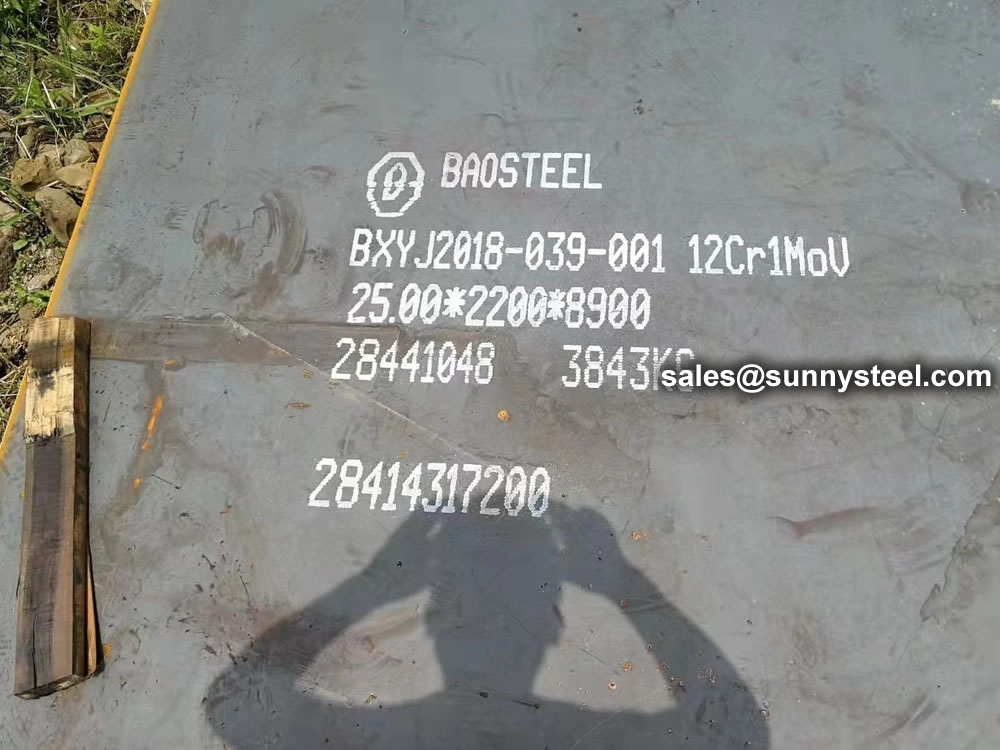

A 12Cr1MoV steel plate is a type of steel plate made from the 12Cr1MoV alloy, which is a low-alloy structural steel. This alloy contains various elements such as chromium, molybdenum, and vanadium, which contribute to its enhanced mechanical properties and high-temperature strength. 12Cr1MoV steel plates are commonly used in the manufacturing of pressure vessels, boilers, and various industrial equipment that operate under high-temperature and high-pressure conditions. These plates exhibit excellent creep resistance, good weldability, and are suitable for applications in industries like power generation, petrochemicals, and more.

12Cr1MoV round steel has higher oxidation resistance and thermal strength. The creep limit of this steel is very close to the creep rupture strength value, and it has high plasticity in the case of permanent stress; the steel has good manufacturability and weldability, but it needs to be preheated to 300°C before welding and stress-relieved after welding. It is a steel grade widely used in high pressure, ultra high pressure, subcritical power plant boiler superheaters, headers and main steam passages. It still has high thermal strength and oxidation resistance at 580°C, and 12Cr1MoV steel plate has higher permanent plasticity. The production process is relatively simple and the welding performance is good, but it is more sensitive to the normalising cooling rate. Long-term use at 580°C will cause pearlite spheroidisation.

12Cr1MoV is an alloy steel plate that is commonly used in various industrial applications.

It is known for its high thermal strength, anti-oxidant properties, and enhanced mechanical properties. The alloy contains elements such as chromium, molybdenum, and vanadium, which contribute to its high-temperature strength and durability.

12Cr1MoV steel is normalized and tempered at high temperatures, where its normal metal organization includes ferrite and pearlite (or local bainite). Compared with the same type of low-alloy pearlitic heat-resistant steel, 12Cr1MoV shows better processability and much higher thermal strength.

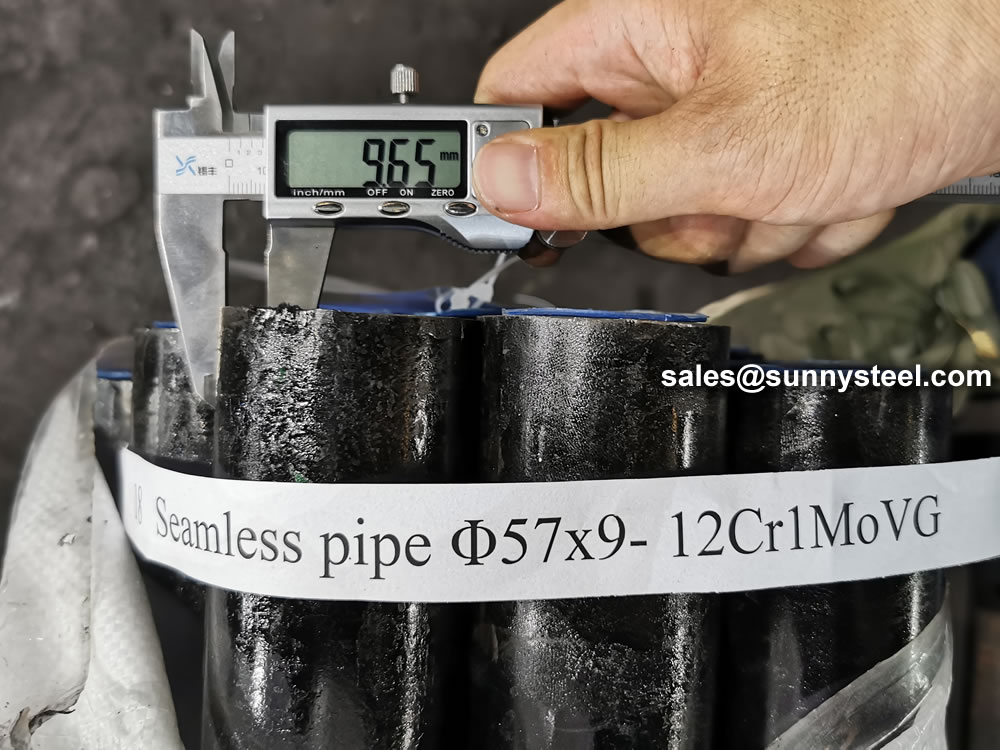

12Cr1MoVG is a type of high-pressure boiler steel used in the production of boilers and pressure vessels. It has a high temperature strength, good thermal conductivity, and excellent corrosion resistance. It is commonly used in the manufacturing of power plant boilers, industrial boilers, and pressure vessels in the petrochemical industry.

12Cr1MoVG is a Cr-Mo-V low alloy heat-resistant steel introduced from the Soviet Union in the 1950s and 1960s. Vanadium is an element that reduces the y-phase region. When dissolved in y-fe, it will inhibit the transformation of ADI to pearlite, which is beneficial to the formation of ADI. The total amount of alloy in 12Cr1MoVG steel is only one half of that of 2.25Cr-1Mo steel, but the endurance strength (580 ° C) is 1.4 times of that of 2.25Cr-1Mo steel. Similar steel grades widely used abroad include ASTM a405 p24 in the United States, bs3604 in the United Kingdom, DIN 13crmov42 in Germany, etc.

The material 12Cr1MoVG is commonly used in the production of high-pressure boiler tubes and piping systems. Its equivalent materials in other standards include:

The equivalent material to 12Cr1MoVG in the ASME standard is ASTM A335 P11. Both materials have similar chemical compositions and mechanical properties, making them suitable for use in high-temperature and high-pressure applications, such as in the construction of boilers and piping systems.

(1)Steel smelting method

GB 5310 12Cr1MoVG steel will be smelted by electric furnace plus furnace refining, oxygen converter plus furnace refining or electroslag remelting method.

(2)Manufacturing methods and requirements for tube blanks

The tube blank can be produced by continuous casting, die casting or hot rolling (forging).

Forging and rolling: the initial forging temperature is 1180-1145 ℃, and the final forging temperature is greater than 850 ℃. After forging, stack cooling is required.

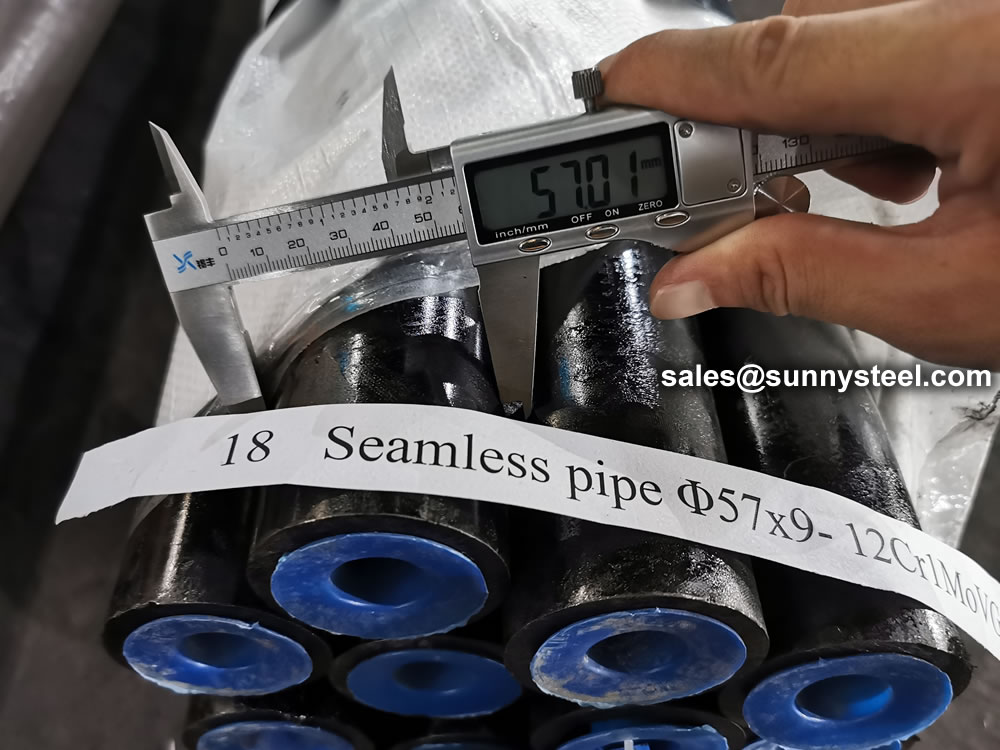

(3)Manufacturing method of steel tube

GB 5310 12Cr1MoVG Steel tubes shall be manufactured by hot rolling (extrusion, expansion) or cold drawing (rolling). Cold and hot processing: small diameter steel pipes can be cold bent without heat treatment after bending. Large diameter thin-walled tube can be cold bent, after bending, it needs to do high temperature heat treatment. Large diameter thick wall pipe needs hot bending. The heating temperature of the hot bend is 980 ° C, and the final bending temperature is more than 800 ℃. After bending, it needs normalizing and adding back.

980 ℃~1 020 ℃,Normalizing,980 °C ~ 1 020 °C normalizing, when the wall thickness is greater than 30 mm, forced cooling; 720 °C ~ 760 °C tempering.

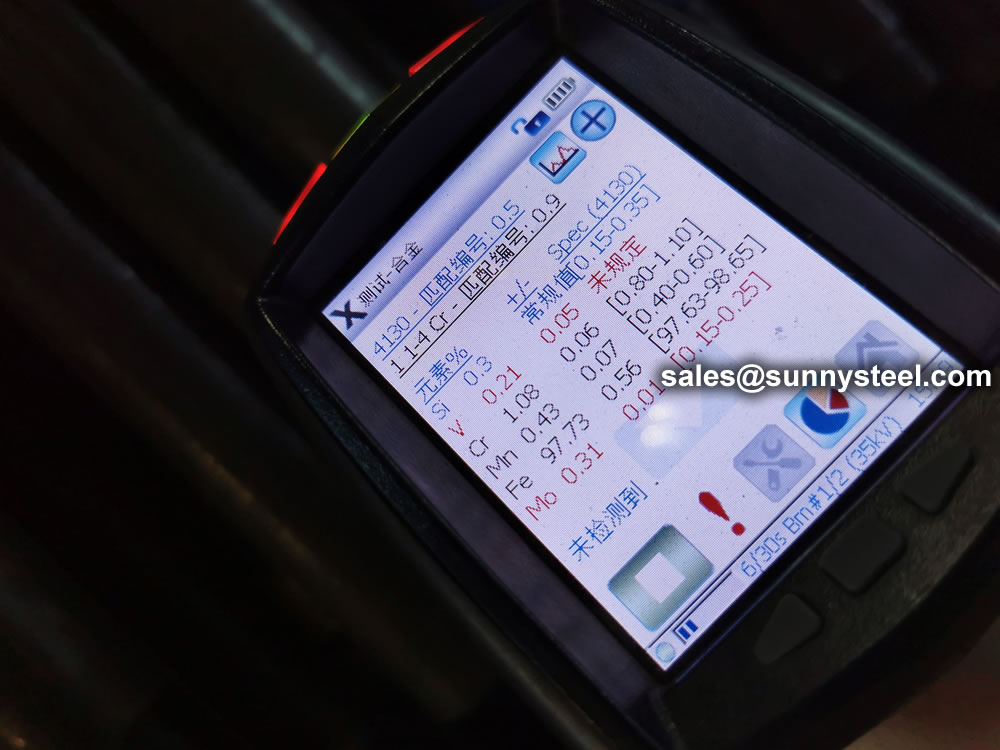

| Element | Content (%) |

|---|---|

| Carbon (C) | 0.08 - 0.15 |

| Silicon (Si) | 0.17 - 0.37 |

| Manganese (Mn) | 0.40 - 0.70 |

| Phosphorus (P) | ≤ 0.035 |

| Sulfur (S) | ≤ 0.035 |

| Chromium (Cr) | 0.90 - 1.20 |

| Molybdenum (Mo) | 0.25 - 0.35 |

| Vanadium (V) | 0.15 - 0.30 |

| Property | Value |

|---|---|

| Tensile Strength | 470 - 640 MPa |

| Yield Strength | ≥ 255 MPa |

| Elongation | ≥ 21% |

| Impact Energy | ≥ 47 J |

| Hardness (HB) | ≤ 179 |

Cr12MoV steel is a widely used cold-work die steel with good hardenability and wear resistance.

12Cr1MoV is a high-quality structural steel known for its high strength, good weldability, and excellent resistance to oxidation and high temperatures. It is commonly used in the manufacture of power plant components, high-pressure pipes, and other applications that require good mechanical properties and corrosion resistance.

12Cr1MoVG is a type of low-alloy heat-resistant steel, which is widely used in high-pressure boilers, steam turbines, power plants, and other industries where high temperature and high pressure are present. It is particularly suitable for the production of large-scale power plant boiler pressure components and other high-temperature and high-pressure equipment, such as superheaters, reheaters, steam pipes, and headers. Its excellent high-temperature strength, oxidation resistance, and creep resistance make it an ideal material for these applications.

Compared with 12CrMoV steel, this steel has higher oxidation resistance and thermal strength. The creep limit of the steel is very close to the value of the endurance strength, and it has high plasticity under the condition of the endurance tension. The technology and weldability of the steel are good, but the preheating is required to 300℃ before welding, and the stress is removed after welding.

It is a kind of steel widely used in superheater, header and main steam pipe of high pressure, ultra high pressure, subcritical power station boiler. At 580℃, it still has high thermal strength, oxidation resistance and durable plasticity. The production process is simple and the welding performance is good, but it is sensitive to the normalizing cooling speed. Long-term use at 580℃ will result in the second kind of temper brittleness caused by the segregation of phosphorus and other impurities at grain boundary. Long–term use will also appear pearlite spherification.

All of them are pearlite type heat-resistant steel, which has high tissue stability and thermal strength when used in high temperature for a long time. Compared with 12Cr1MoV steel, Cr content is higher, with higher oxidation resistance and thermal strength. Creep limit is close to the endurance strength value and has higher plasticity under the condition of endurance tension. The technology and weldability of the steel are good, but the preheating is required to 300℃ before welding, and the stress is removed after welding.

12CrMoV and 12Cr1MoV alloy steel, API 5L X52 steel with the thickness range is 1.2-40mm, the width range is 1220-4200mm, and the length range is 5000-18000mm. API 5L X52 steel’s mechanical properties is the yield strength 300MPa, and the tensile strength 460MPa. To be specified in details: Maximum content for C≤0.28%, Mn≤1.4%, P≤0.030%, S is 0.030%, V+Nb+Ti≤0.15%, Copper maximum is 0.50%, nickel maximum 0.50%, chromium 0.50%, Molybdenum 0.15%.

It is very important for a company to have a sound after-sales service system, which better guarantees the interests of customers and increases the reliability of the company’s products in the hearts of customers. Our company has a dedicated after-sales service team and good after-sales service reputation, and has been recognized by customers over the past decades. Whenever there is problem about our 12CrMoV and 12Cr1MoV alloy steel steel materials during application on the user site, our after-sales service persons will assist to find solutions at the first time.