ASTM A335 P5

Alloy seamless pipes

The utilization of 20G seamless pipes is imperative for the boiler in Uzbekistan.

These pipes, known for their high-quality and durability, play a crucial role in ensuring the efficient functioning of the boiler system.

20G refers to a specific type of seamless steel pipe that is well-suited for high-pressure and high-temperature applications, making it an ideal choice for boiler systems. The seamless nature of these pipes ensures a reliable and leak-free operation, contributing to the overall safety and performance of the boiler.

Whether it's for power generation, industrial processes, or heating applications, 20G seamless pipes demonstrate exceptional strength and resilience, meeting the stringent requirements of boiler installations in Uzbekistan.

The versatile nature of 20G seamless steel pipes makes them suitable for a range of industrial applications:

When incorporating 20G seamless steel pipes into industrial systems, the following factors should be considered:

20G is a type of high-quality carbon structural steel, commonly used in the production of boiler tubes and pressure vessels due to its excellent mechanical properties and heat resistance.

20G is the steel material of GB 5310- 2008. GB 5310- 2008 standard is applicable to seamless tubes for making steam boiler whose pressure is high or higher and seamless tubes used as pipelines.

GB 5310 is a Chinese standard that outlines the specifications for seamless steel tubes used in high-pressure boilers. The designation "20G" refers to the material grade of these tubes, indicating that they are made from 20G steel, a low-carbon steel known for its excellent heat transfer properties and high tensile strength.

| Chemical elements | Data |

|---|---|

| Carbon | 0.17-0.23 |

| Silicon | 0.17-0.37 |

| Manganese | 0.35-0.65 |

| Phosphorus(max) | 0.03 |

| Sulfur(max) | 0.03 |

| Chromium(max) | 0.25 |

| Molybdenum(max) | 0.15 |

| Cuprum(max) | 0.2 |

| Nickel(max) | 0.25 |

| Vanadium(max) | 0.08 |

| Properties | Data |

|---|---|

| Yield Strength (Mpa) | 410-550 |

| Tensile Strength (Mpa) | 245 |

| Elongation (%) | 22 |

| W.T.(S) | Tolerance of W.T. | |

|---|---|---|

| <3.5 | +15%(+0.48mm min) | |

| -10%(+0.32mm min) | ||

| 3.5-20 | +15%,-10% | |

| >20 | D<219 | ±10% |

| D≥219 | +12.5%,-10% | |

20G High Pressure Boiler Pipe, GB5310 20G boiler steel pipe, 20G boiler steel pipe, 20G boiler pipe

Delivery Condition:

Annealed, Normalized, Normalized and Tempered

Inspection and Test:

Chemical Composition Inspection, Mechanical Properties Test(Tensile Strength,Yield Strength, Elongation, Flaring, Flattening, Bending, Hardness, Impact Test), Surface and Dimension Test,No-destructive Test, Hydrostatic Test.

Surface treatment:

Oil-dip, Varnish, Passivation, Phosphating, Shot Blasting

Delivery status

The steel tubes shall be delivered in a heat treated condition.

Length: 5800mm; 6000mm; 6096mm; 7315mm; 11800mm; 12000mm; and so on.

Max length: 16000mm, also U bending can be offered.

Note:

This inventory is part of the inventory, demand and other models in stock or order materials, please contact us.

With years of expertise, we provide a diverse array of steel tube processing options. From sawing and machining tube blanks to intricate bending and upsetting operations, we actively assist you throughout your projects.

Our capabilities extend to eccentricity reduction and concentricity enhancement through turning and grinding. We excel in creating complex geometries using processes like rotary swaging and axial forming. Additionally, we offer property modifications via partial heat treatment, ensuring tailored solutions for your specific needs.

Seamless steel pipe is regularly used in the transportation of fluids such as water, natural gas, waste and air. It is also regularly required in many high-pressure, high-corrosive environments such as in the oil & gas, power generation and pharmaceutical industries. Some common uses of seamless pipes include:

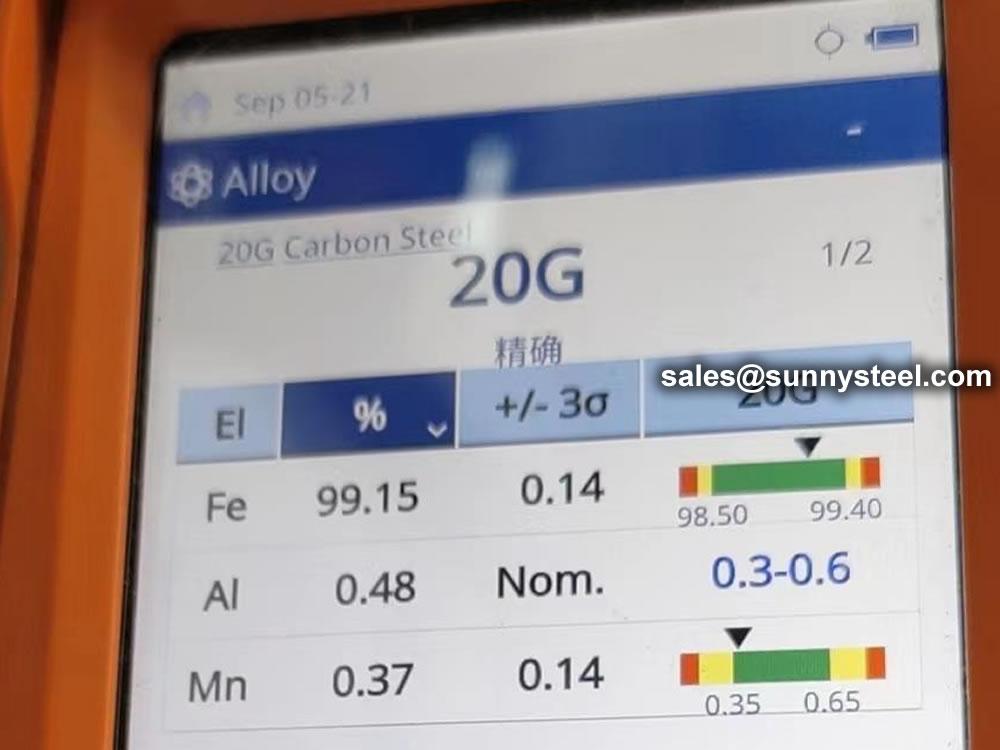

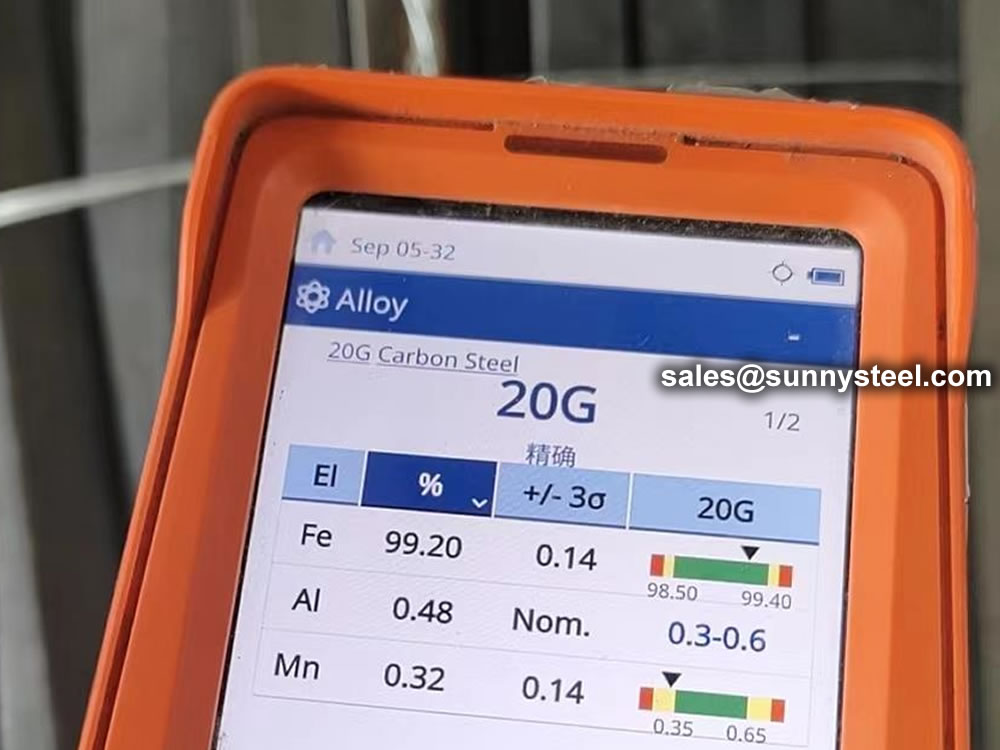

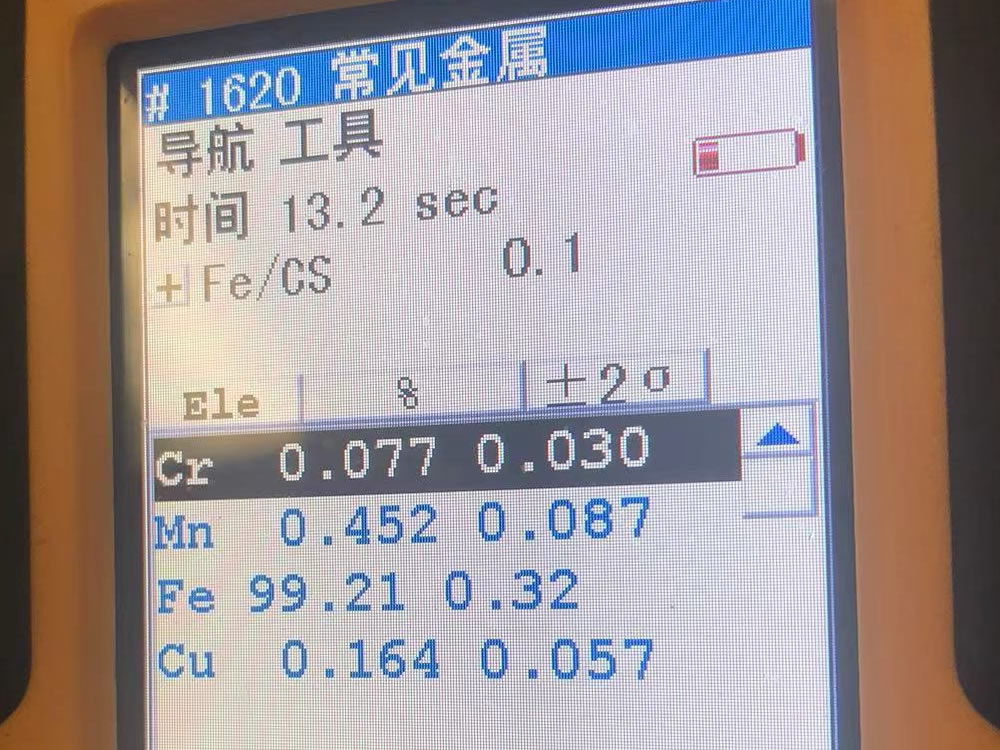

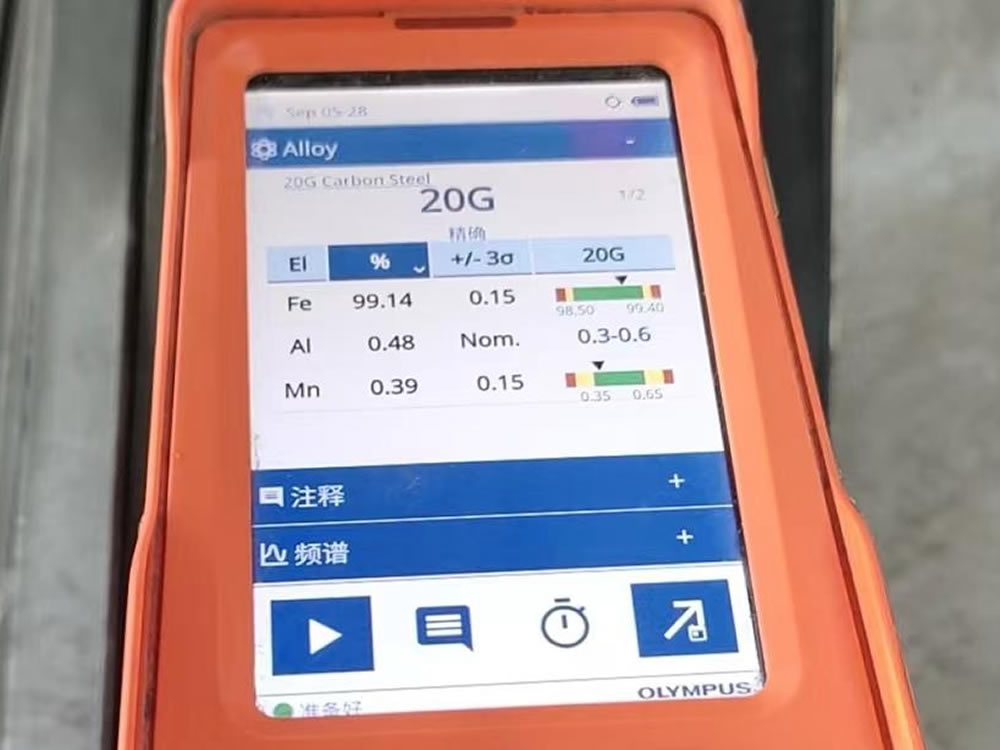

Chemical composition inspection, mechanical properties test(tensile strength,yield strength, elongation, flaring, flattening, bending, hardness, impact test), surface and dimension test,no-destructive test, hydrostatic test.

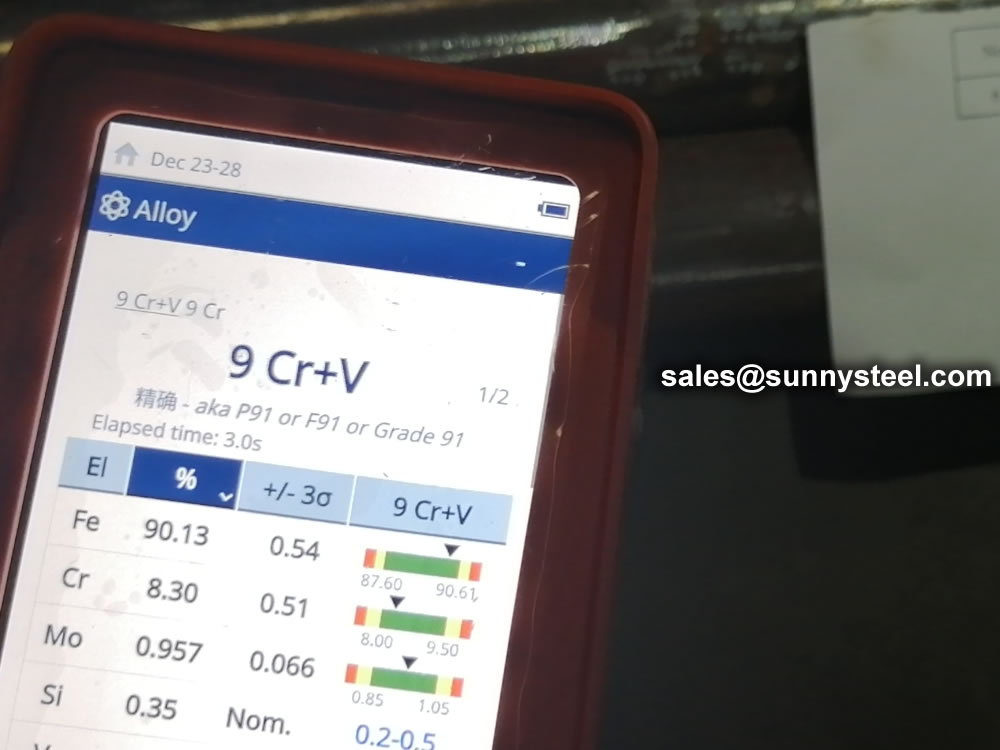

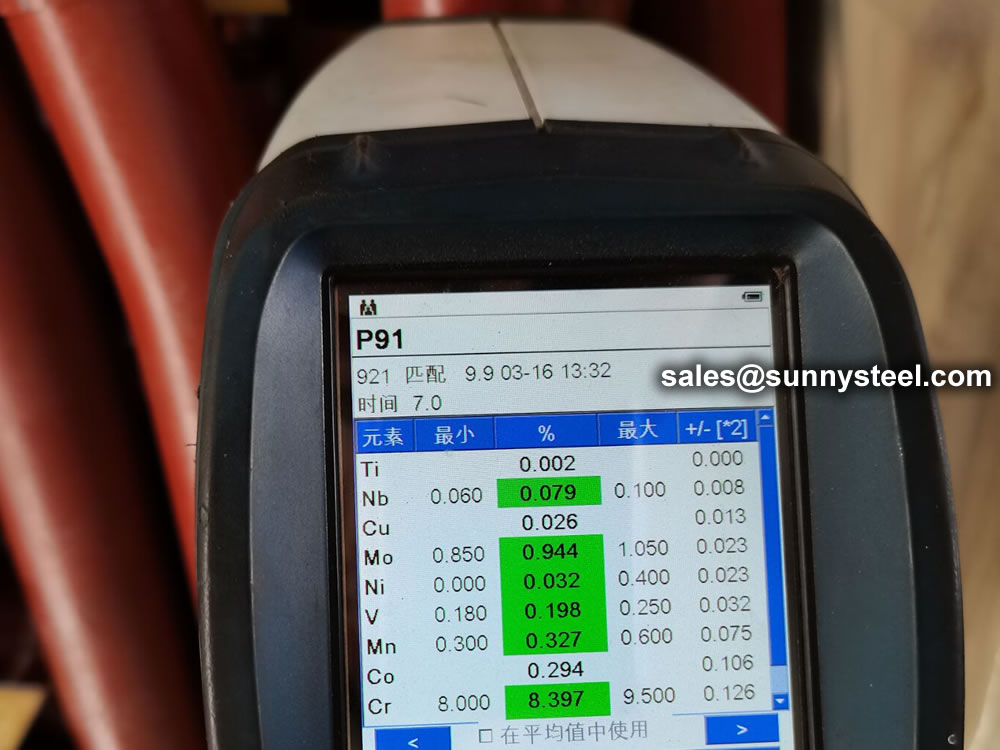

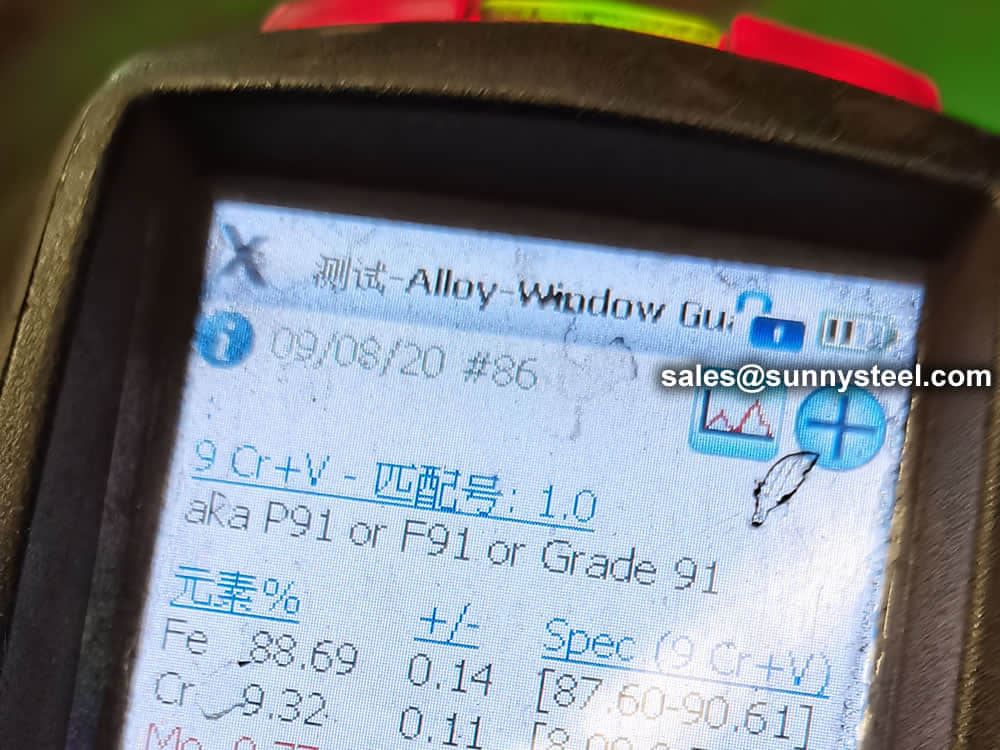

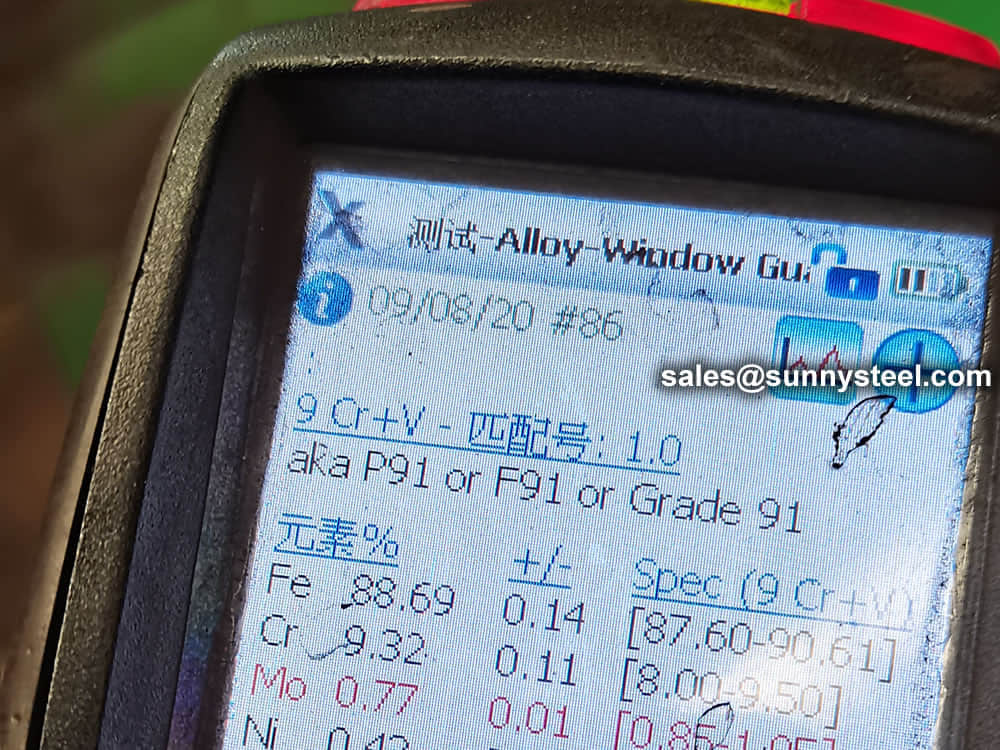

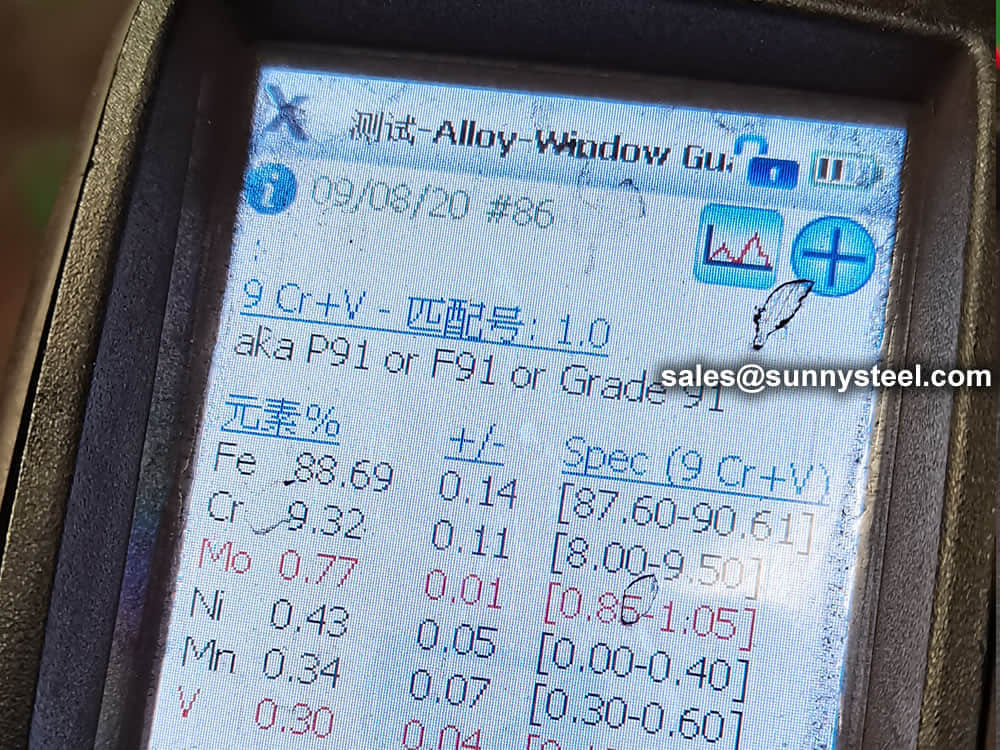

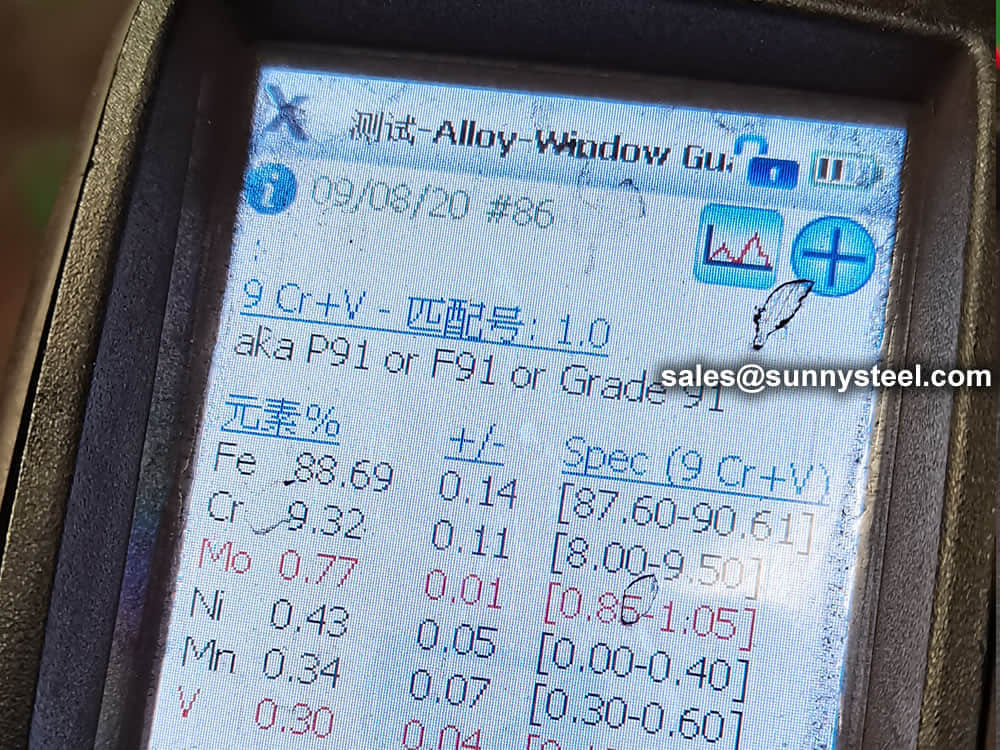

identification of the chemical composition of the metal used to manufacture the fitting. Uses PMI sensors, including X-ray fluorescence or optical emission spectrometry.

Steel pipe delivery status(condition): cold / hard (BK), cold / soft (BKW), after cold stress relief annealing (BKS), annealing (GBK), normalized (NBK).

| Term | Symbol | Explanation |

|---|---|---|

| Cold-finished/hard (cold-finished as-drawn) | BK | No heat treatment after the last cold-forming process. The tubes therefore have only low deformability. |

| Cold-finished/soft (lightly cold-worked) | BKW | After the last heat treatment there is a light finishing pass (cold drawing) With proper subsequent processing, the tube can be cold-formed (e.g. bent, expanded) within certain limits. |

| Annealed | GBK | After the final cold-forming process the tubes are annealed in a controlled atmosphere or under vacuum. |

| Normalized | NBK | The tubes are annealed above the upper transformation point in a controlled atmosphere or under vacuum. |

The general cold strip mills, volume should go through continuous annealing (CAPL unit) to eliminate cold hardening and rolling stress, or batch annealing reach the mechanical properties of the corresponding standard specifies. Cold rolled steel surface quality, appearance, dimensional accuracy better than hot-rolled plate, and right-rolled thin product thickness is about 0.18mm, so the majority of users favor.

Cold rolled steel coil substrate products deep processing of high value-added products. Such as electro-galvanized, hot dip galvanized, electro-galvanized fingerprint resistant, painted steel roll damping composite steel, PVC laminating steel plates, etc., so that the excellent quality of these products has a beautiful, high resistance to corrosion, has been widely used.

Cold rolled steel coil finishing after annealing, cut the head, tail, trimming, flattening, smooth, heavy volume, or longitudinal clipboard. Cold-rolled products are widely used in automobile manufacturing, household electrical appliances, instruments, switches, buildings, office furniture and other industries. Steel plate strapping package weight of 3 to 5 tons. Flat sub-volume typically 3 to 10 tons / volume. Coil diameter 6m.

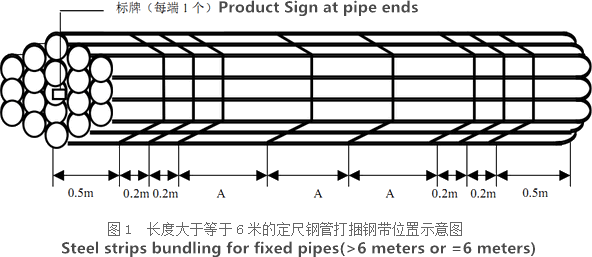

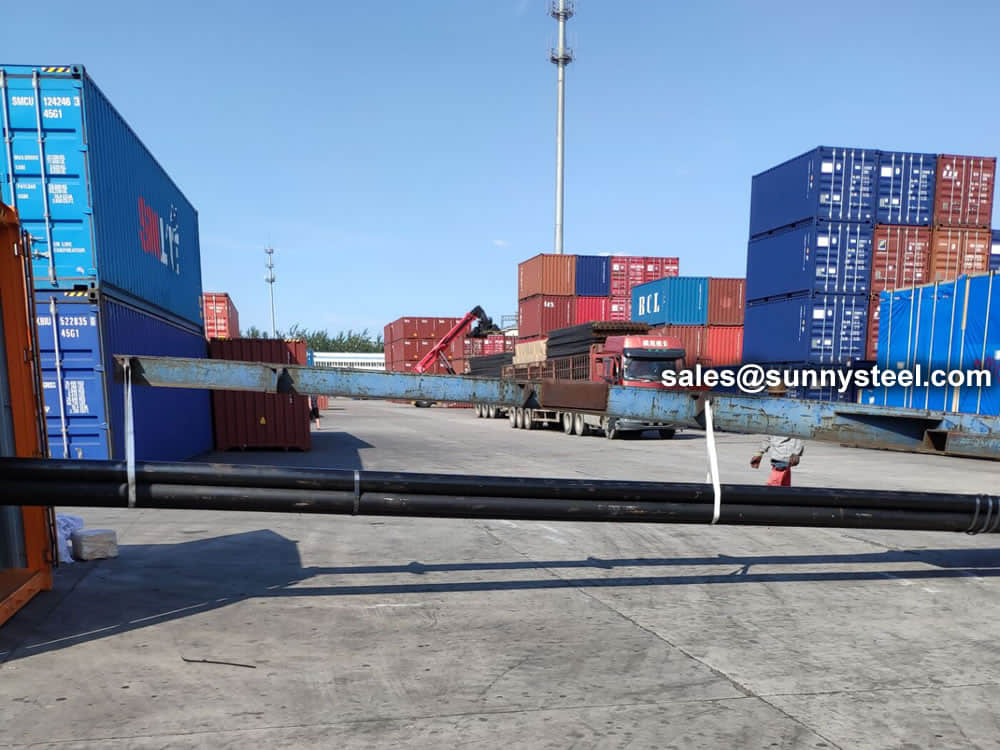

Bare packing/bundle packing/crate packing/wooden protection at the both sides of tubes and suitably protected for sea-worthly delivery or as requested.

There are probably hundreds of different methods for packing a pipe, and most of them have merit, but there are two principles that are vital for any method to work prevent rusting and Sea transportation security.

Our packing can meet any needs of the customers.