Bearing Pipes

Pipes designed for bearing loads, offering high strength and durability.

Low temperature steel pipe, also known as low temperature carbon steel pipe, is specifically designed to withstand low temperatures and is commonly used in applications where cryogenic conditions are present.

Low-temperature service pipes are typically manufactured from materials that can endure extreme cold, such as Low-Temperature Carbon Steel (LTCS) or other alloy steels. These materials are formulated to maintain durability and avoid fractures under conditions that would make standard carbon steels brittle. Common grades include ASTM A333, ASTM A334, and ASTM A352. These grades are engineered with low carbon content and controlled levels of manganese, silicon, and other alloying elements to ensure they remain ductile in temperatures as low as -50°F (-45°C).

Low-temperature service pipes are known for several crucial properties:

These pipes are essential for industries where low temperatures are a regular part of operations. Key applications include:

The most widely used specifications for low-temperature service pipes include:

Low temperature pipe refers to pipes specifically designed to withstand and operate effectively in environments with low temperatures, typically below 0°C (32°F). These pipes are often used in industries such as oil and gas, petrochemicals, and refrigeration, where fluids need to be transported or stored at low temperatures. They are constructed from materials that can maintain their mechanical properties and structural integrity even in extremely cold conditions, ensuring the safe and efficient transportation of fluids. Additionally, low temperature pipes are insulated to prevent heat transfer and maintain the desired temperature of the fluid being transported.

Compared with austenitic stainless steel and duplex stainless steel, there are many comprehensive advantages of ferrite alloy steels for low temperature service, such as higher strength, better rigidity and lower expansion coefificient. There is not only better stability but aslo higher heat transfer efficiency. Tube & pipe for low-temperature service can be widely used in low temperature engineering. ASTM/ASME A/SA-333 Grades allow for cold temperature service to minus 150 degrees F. Material is always provided in the normalized condition at a minimum and Charpy Impact tested to a specific temperature range to assure compliance with the required service temperature.

This specification covers seamless and welded steel pipe for low temperature service.

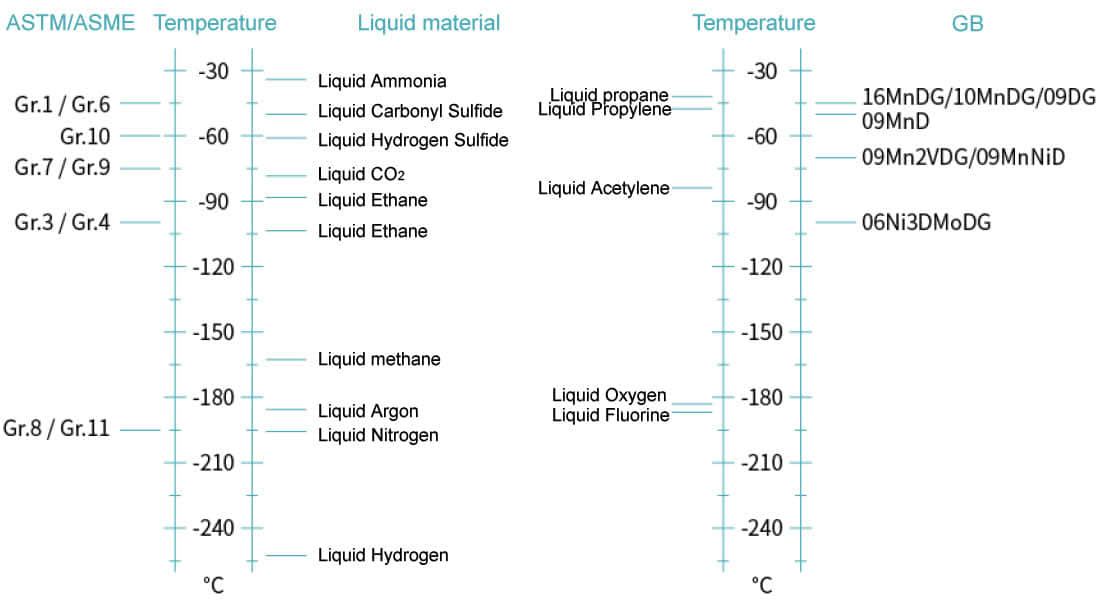

We usually call the steel used the temperature range -10 to -273℃ as low-temperature steel or cryogenic steel According to alloying element content and structure, cryogenic steels can be divided into: Aluminum killed C-Mn steel such as 06MnVTi, 06MnVal, 09Mn2Vre, 06MnNb steel, low alloy ferric body low-temperature steel 0.5Ni, 2.5Ni, 3Ni, 3.5Ni, etc., Martensiform low-temperature steels such as 9Ni, 5Ni steel, high alloy austenitic low-temperature steels such as 1Cr18Ni9Ti and 20Mn23Al and so on.

The effect of alloying elements in low-temperature steels mainly refers to its effect on the low-temperature toughness of steels:

Manganese can improve obviously the low-temperature toughness of steel. Manganese mainly exists in the form of solid solution in steel and plays the role of solid solution strengthening. In addition, manganese is an element that enlarges the austenite region and reduces the transformation temperature (A1 and A3). It is easy to obtain fine and ductile ferrite and pearlite grains, which can increase the maximum impact energy and significantly reduce the brittle transition temperature. In general, the Mn/C ratio should be equal to 3, which can not only reduce the brittle transition temperature of steel, but also compensate for the decrease of mechanical properties caused by the decrease of carbon content due to the increase of Mn content.

Nickel can alleviate the tendency of brittle transition and significantly reduce the temperature of brittle transition. The effect of nickel on improving the low-temperature toughness of steel is 5 times that of manganese, that is, the brittle transition temperature decreases by 10℃ with the increase of nickel content by 1%. This is mainly because of nickel with carbon, absorbed by the solid solution and reinforcement, nickel also makes a move to the left point of eutectoid steel eutectoid point to reduce the carbon content, reduce the phase transition temperature (A1 and A2), in comparison with the same carbon content of carbon steel, decrease in the number of ferrite and refining, pearlite populations (the carbon content of pearlite is also lower than carbon steel). The experimental results show that the main reason why nickel increases the toughness at low temperature is that nickel-containing steel has more movable dislocations at low temperature and is easier to cross slip. For example, medium alloy low carbon martensiform low-temperature steel 9Ni steel, has high low-temperature toughness, can be used for -196℃. The 5Ni steel developed on the basis of 9Ni steel has good low-temperature toughness at -162~-196℃.

With the increase of carbon content, the brittle transition temperature of steel increases quickly and the welding property decreases, so the carbon content of low-temperature steel is limited to less than 0.2%.

Phosphorus, sulfur, arsenic, tin, lead, antimony: these elements are not conducive to the low-temperature toughness of steel.

They segregate in the grain boundary, which reduces the surface energy and resistance of the grain boundary, and causes the brittle crack to originate from the grain boundary and extend along the grain boundary until the fracture is complete.

Phosphorus can improve the strength of steel, but it will increase the brittleness of steel, especially at low temperatures. The brittle transition temperature is obviously increased, so its content should be strictly limited.

These elements will increase the brittle transition temperature of steel. Deoxidized silicon and aluminum killed steels can improve the toughness at low temperatures, but because silicon increases the brittle transition temperature of steels, aluminum killed steels have a lower brittle transition temperature than silicon killed steels.

| Steel Grade | GB(China) | ASME(USA) | DIN/EN(Euro) | JIS(Jpan) | Application |

|---|---|---|---|---|---|

| Carbon steel | 10 | A106 | St35.8 | STB340 | Economizer tube Water wall tube, pipeline, header pipe, Petrochemical furnace tube, heat exchange tube |

| 20 | SA-106B | St45.8 | STB410 | ||

| 20G | SA-106C | P235GH | STB510 | ||

| 20MnG | SA-192 | P265GH | |||

| 25MnG | SA-210A1 | ||||

| Q345B/C/D/E | SA-210C | ||||

| Mo steel | 15MoG | SA-209 T1 | 16Mo3 | 15Mo3 | Water wall tube Superheater tube Reheater tube |

| 20MoG | SA-209 T1a | 16Mo3 | |||

| SA-209 T1b | |||||

| Cr-Mo Steel | 12Cr1MoG | 12Cr1MoV | Superheater tube Reheater tube, Pipeline, Header pipe, Petrochemical furnace tube, Heat exchange tube |

||

| Cr-Mo-V steel | 12Cr2MoWVTiB | 14MoV63 | |||

| Cr-Mo-Steel | 12CrMoG | T11/P11 | 10CrMo5-5 | STB20 | |

| Cr-Mo-W Steel | 15CrMoG | T12/P12 | 12CrMo4-5 | STB22 | |

| Cr-Mo Steel | 12Cr2MoG | T22/P22 | 10CrMo9-10 | STB23 | Superheater tube, Reheater tube, Main steam pipe, Pipleline, Header pip, Petrochemical furnace tube, Heat exchange tube |

| Cr-Mo-W steel | 10Cr9Mo1VNbN | T23/P23 | 7CrWVMoNb9-6 | STB24 | |

| 10Cr9MoW2VNbBN | T24/P24 | 7CrMoVTIB10-10 | STB25 | ||

| 12Cr1Mo | T5/P5 | X10CrMoVNb9-1 | STB26 | ||

| 12Cr5Mol/NT | T9/P9 | X10CrWMoVNb9-2 | |||

| 12Cr9Mol/NT | T91/P91 | X11CrMo5+l/NT | |||

| T92/P92 | X11CrMo9-1+l/NT | ||||

| Carbon steel | 16MnDG | A333-1 | STPL380 | Tube & pipe for Low-temperature service | |

| Ni steel | 10MnDG | SA-333-1 | STPL450 | ||

| 09DG | A333-6 | ||||

| SA-333-6 | |||||

| A333-3 | |||||

| SA-333-3 | |||||

| Austentic Stainless steel | --- | AP304 TP304H | --- | Superheater tube, Reheater tube | |

| TP321 TP321H | |||||

| TP347 TP347H | |||||

| TP316 TP316H | |||||

| S30432 TP310HCbN |