Bearing Pipes

Pipes designed for bearing loads, offering high strength and durability.

Seamless steel tubes for mechanical and automobile usage for backbone of automobile and rear axle tube, manufacturing and processing of precision equipments, instruments and apparatus.

Standard packaging is used to prevent damage to the material during shipping. If you need custom packaging for your order, please let us know what your requirements are and we will accommodate your specific needs.

Delivery Condition: GBK, BKS, BK, BKW, NBK

Inspection and Test: Chemical Composition, Mechanical Properties, Visual and Dimension Test, NDT, Grain Size Test

Surface treatment: Oil-dip, Varnish, Shot Blasting

Your tubular products representative will be happy to work with you to develop the information that is required. Sunny Steel supply a 1/2 million foot inventory of carbon steel pressure tubing including boiler tubes, condenser tubes and heat exchanger tubes all made in the China.

Our carbon steel pressure tubing inventory is manufactured in accordance with ASME SA-178 A and/or ASME SA-214 in diameters of 3/4″ through 4”.

ASTM A519 covers several grades of carbon and alloy steel seamless mechanical tubing. The standard is also acceptable in the manufacture of piping.

| Grade Designation | C | Mn | P≤ | S≤ | Si | Cr | Mo |

|---|---|---|---|---|---|---|---|

| 1008 | ≤0.10 | 0.30-0.50 | 0.04 | 0.05 | - | - | - |

| 1010 | 0.08-0.13 | 0.30-0.60 | 0.04 | 0.05 | - | - | - |

| 1018 | 0.15-0.20 | 0.60-0.90 | 0.04 | 0.05 | - | - | - |

| 1020 | 0.18-0.23 | 0.30-0.60 | 0.04 | 0.05 | - | - | - |

| 1025 | 0.22-0.28 | 0.30-0.60 | 0.04 | 0.05 | - | - | - |

| 1026 | 0.22-0.28 | 0.60-0.90 | 0.04 | 0.05 | - | - | - |

| 4130 | 0.28-0.33 | 0.40-0.60 | 0.04 | 0.05 | 0.15-0.35 | 0.80-1.10 | 0.15-0.25 |

| 4140 | 0.38-0.43 | 0.75-1.00 | 0.04 | 0.05 | 0.15-0.35 | 0.80-1.10 | 0.15-0.25 |

| Grade | Condition | MPa Tenslle Point | Yield Point | Elongation |

|---|---|---|---|---|

| 1020 | CW | ≥414 | ≥483 | ≥5% |

| SR | ≥345 | ≥448 | ≥10% | |

| A | ≥193 | ≥331 | ≥30% | |

| N | ≥234 | ≥379 | ≥22% | |

| 1025 | CW | ≥448 | ≥517 | ≥5% |

| SR | ≥379 | ≥483 | ≥8% | |

| A | ≥207 | ≥365 | ≥25% | |

| N | ≥248 | ≥379 | ≥22% | |

| 4130 | SR | ≥586 | ≥724 | ≥10% |

| A | ≥379 | ≥517 | ≥30% | |

| N | ≥414 | ≥621 | ≥20% | |

| 4140 | SR | ≥689 | ≥855 | ≥10% |

| A | ≥414 | ≥552 | ≥25% | |

| N | ≥621 | ≥855 | ≥20% |

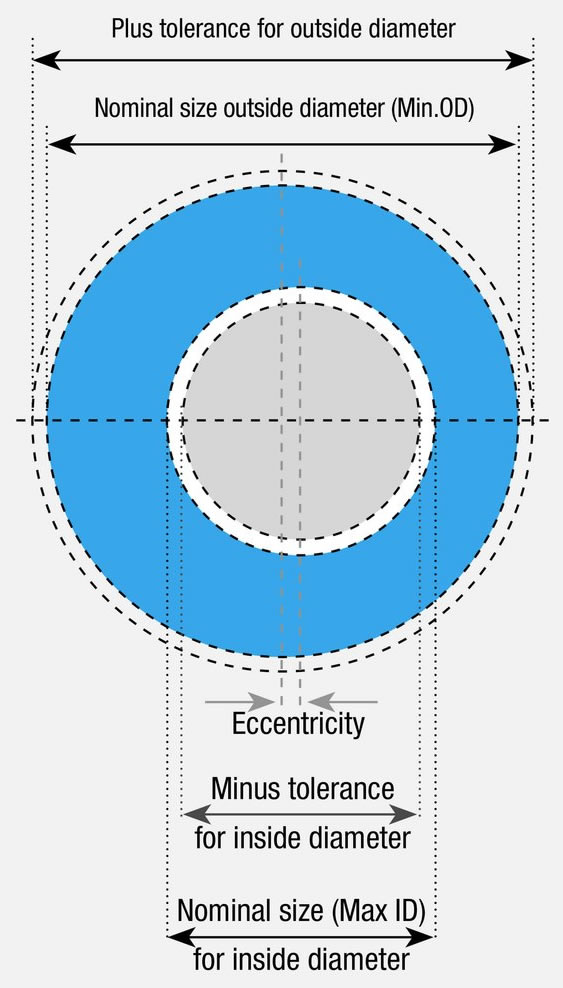

Hollow bar is manufactured in the size ranges most frequently required by mechanical engineering manufacturing companies. However, in the case of hollow bar, the tolerance range for the outside diameter lies in the plus range, and for the inside diameter in the minus range. The wall thickness tolerance is determined by the degree of centre offset; this is due to the effect of the tolerance for the outside and inside diameter, the wall thickness and the centre offset. (See diagram below.)

In the case of mechanical tubing to ASTM A 511, the outside diameter and the wall dimensions generally lie in the centre of the tolerance range. Thus, when ordering product for machining it is important to take into account the differences in the tolerances between the hollow bar and the ASTM A 511 mechanical tubing specifications. In most cases the machining set up is based on centring the outside diameter.

Tubular products seamless mechanical tubing is furnished in both cold-drawn and hot finished form in a wide range of sizes, from 1.375″ to 7.750″ OD and from 0.188″ to 1.625″ wall thickness.

| Abbr. | Corresponding | Application |

|---|---|---|

| A511 | ASTM A511 / A511M | Specification for Seamless Stainless Steel Mechanical Tubing |

| A512 | ASTM A512 / ASME SA512 | Specification for Cold-Drawn Buttweld Carbon Steel Mechanical Tubing |

| A513 | ASTM A513 / A513M | Specification for Electric-Resistance-Welded Carbon and Alloy Steel Mechanical Tubing |

| A519 | ASTM A519 / A519M | Specification for Seamless Carbon and Alloy Steel Mechanical Tubing |

| A554 | ASTM A554 | Specification for Welded Stainless Steel Mechanical Tubing |

SCM4 grade seamless steel pipes find applications in diverse industries, including machinery manufacturing, construction, and engineering. Their high-quality construction and reliability make them a preferred choice for various industrial applications.

Tubing used for mechanical and light gauge structural applications. Mechanical tube is produced to meet specific end use requirements, specifications, tolerances and chemistries. This allows for more specific property uniformity throughout the tube compared to standard pipe or tube.

Our factory has been proudly certified with the IATF 16949 Automotive Quality Management System for many years. We specialize in producing steel tubes with exceptional characteristics:

1. Bending without Cracking: Our steel tubes can be bent without the risk of cracking, ensuring their structural integrity in various applications.

2. Excellent Ductility: These tubes exhibit excellent ductility, making them suitable for applications requiring flexibility and resistance to deformation.

We offer a range of specialized steel tubes, including:

- Safety Airbag Tubes: Designed for the automotive safety airbag systems, these tubes are engineered for reliability and performance.

- Stabilizer Bar Tubes (16MnCr5 Material): These tubes are ideal for stabilizer bars in the automotive industry, featuring 16MnCr5 material for strength and durability.

- Automotive Motor Shaft Tubes (34MnB5 Material): Tailored for use in automotive electric motor shafts, these tubes are crafted from 34MnB5 material known for its mechanical properties.

Our steel tubes have a smooth surface finish, meeting the quality requirements for subsequent processes such as electrophoresis, painting, powder coating, galvanizing, and chrome plating.

We take pride in delivering high-quality steel tubes that adhere to the stringent standards of the automotive industry, ensuring safety, durability, and performance in your applications. If you have specific requirements or inquiries, please feel free to contact us for more details.