Bearing Pipes

Pipes designed for bearing loads, offering high strength and durability.

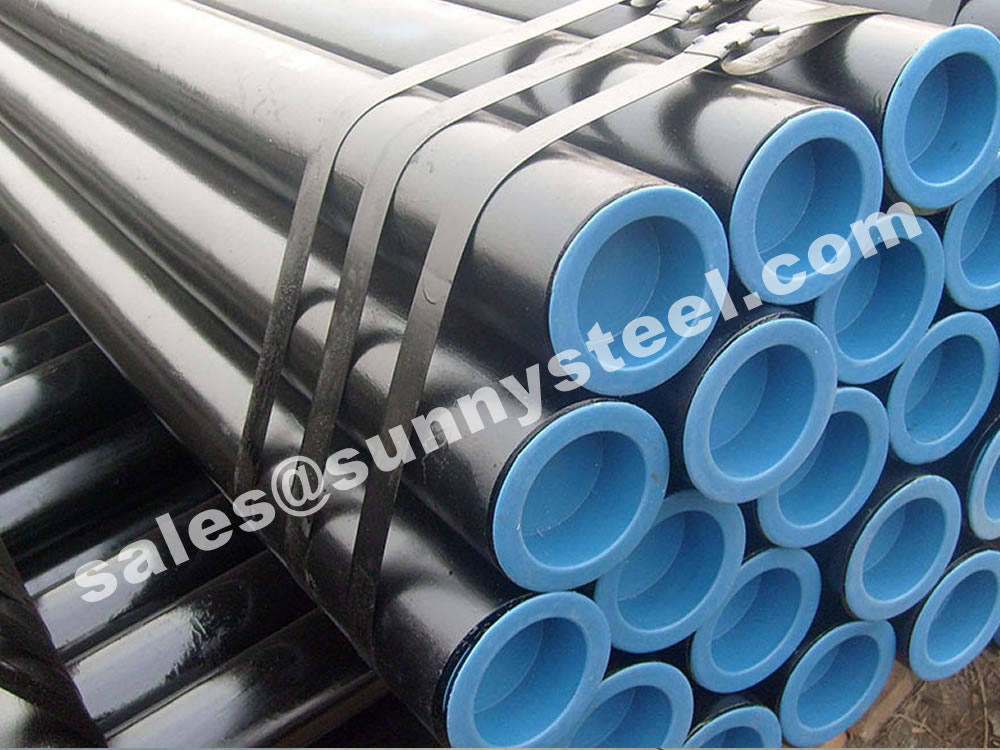

Fluid steel tubes, also known as fluid tubes are commonly used in various industries for fluid transportation purposes.

Fluid Steel Tubes are specifically designed for efficient and reliable fluid transport across a wide range of industries. Known for their strength, corrosion resistance, and adaptability, these tubes are suitable for conveying water, oil, gas, and other fluids in both low and high-pressure applications.

Outer Diameter: Φ 8mm ~ Φ 89mm

Wall Thickness: 2mm ~ 10mm

10, 20, 15CrMo, 12Cr2Mo, L245N, L360N, H40, J55, K55, N80, L80, C90, T95, P110, C110, Q125, X42, X46, X52, X56, X60, X65, etc.

GB/T 8163-2018, GB/T 9948-2013, GB 6479-2013, GB/T 19830-2011, GB/T 9711-2017, API SPEC 5CT, API SPEC 5L, ISO 11960, etc.

Liquid steel has high purity, excellent geometrical dimension and good performance for processing.

A fluid tube is a steel pipe with a hollow cross-section, from end to end, without welds. The steel pipe has a hollow section, and is widely used as a pipeline for transporting fluids to transport oil, natural gas, gas, water and certain solid materials. Compared with solid steel such as round steel, the steel pipe is lighter in weight when the bending and torsional strength is the same. and steel scaffolding used in building construction.

The fluid pipe is a pipe specially used for conveying medium with fluid properties. In addition to liquid media such as water, oil, and solution, solid media such as cement, grain, and pulverized coal can also flow under certain conditions.

Fluid pipes can be made of steel, non-ferrous metals such as copper, titanium, or even non-metallic materials such as plastics. The fluid pipe must have a hollow section, but it can also be square, triangular or any other shape. Some equipment is limited by conditions and must use a rectangular pipe, but most of them still use round pipes. The circular tube has the smallest circumference/area ratio of all geometrical sections, that is, the largest inner section can be obtained with the same amount of material.

Fluid pipes are hollow cross section, no welded joint from start to finish. Steel tube with a hollow cross-section, for a large number of pipe conveying fluid pipeline to transport oil, natural gas, coal gas, water and some solid materials.

Compared to solid steel such as steel pipes and round steel in flexural torsional strength the same, lighter, is an economic section steel, widely used in the manufacture of structural parts and mechanical parts, such as drill pipe, automotive transmission, bike frame and steel used in construction scaffolding.

Having the nature of the fluid medium, in addition to the liquid medium such as water, oil, solution, etc., cement, grain, coal and other solid media, under certain conditions, can also be mobile.

Fluid tubes made of steel, copper, titanium and other non-ferrous metals manufacturing, and even can be manufactured from plastic and other non-metallic materials. Must be fluid tube having a hollow cross-section, but can also be square, triangular or any other shape, and some of the equipment subject to conditions, it must be used a rectangular tube, but most or using round tube. Tube in all geometric cross-section having a minimum perimeter / area ratio of the maximum internal cross-section, i.e. under conditions using the same amount of materials can be obtained.

Steel pipe due to its low cost, high strength, in the modern society, the fluid delivery to be widely applied. Steel pipe into seamless steel pipe and welded pipe two categories according to their production process, which welded pipe is divided into ERW (ERW), spiral welded pipe (SSAW), submerged arc welded pipe (UOE). In the past, the fluid tubes to the traditional use of seamless steel pipe, materials science, the molding process, the development and progress of the crew and equipment, welded pipe has been a great development.

Welded pipe has the advantages of better than seamless pipe wall thickness uniformity, high precision, low energy consumption, high production efficiency, demanding oil and gas pipeline (API standard), almost one hundred percent use of seamless pipe, today in the United States, Japan, Europe and the developed countries, more than 95% have been welded pipe replaced.

With ordinary steel pipe, the welded pipe for transporting fluid tubes have different requirements:

Structural tube is a general structural steel tube, referred to as structural tube. It is suitable for seamless steel tubes for general structures and mechanical structures. The most common material is carbon steel, which can be divided into two types: ordinary carbon structural steel and high-quality carbon structural steel. There are many uses and a large amount of use. It is mainly used in railways, bridges, and various construction projects to manufacture various metal components that bear static loads, as well as unimportant mechanical parts that do not require heat treatment and general weldments.

Structural seamless tubes are steel tubes used to build various structures because they are used to build various structures that need to achieve several properties.

The fluid tube standard is suitable for general seamless steel tubes for conveying fluids. Fluid seamless tubes are steel pipes used to transport various liquids and gases such as oil, natural gas, natural gas and water. Because it is used for transportation, fluid pipelines also have their own remarkable characteristics.

1. Good air tightness, no leakage is allowed during transportation, otherwise the gas will leak, and the consequences will be disastrous.

2. Prevent corrosion, because many transported objects are corrosive, if corrosion occurs, the entire project will be affected.

3. The smoothness of the pipe is very demanding, and it needs to meet the requirements before it can be made into a fluid pipe.

First, strictly speaking, they cannot be shared. Structural tubes require good pressure bearing capacity, while fluid pipes require good sealing performance. Therefore, the uses of the two are very different. Try not to use the wrong area.

Secondly, structural pipes have high requirements on cost, otherwise some steel tubes are not up to standard in terms of corrosion resistance or pressure bearing capacity, and are easily damaged. If water and food are transported by fluid pipelines, the hygienic requirements are stricter. It can be shared under special circumstances, and some features are the same, as long as the environmental requirements are not too harsh, they can be shared.