Bearing Pipes

Pipes designed for bearing loads, offering high strength and durability.

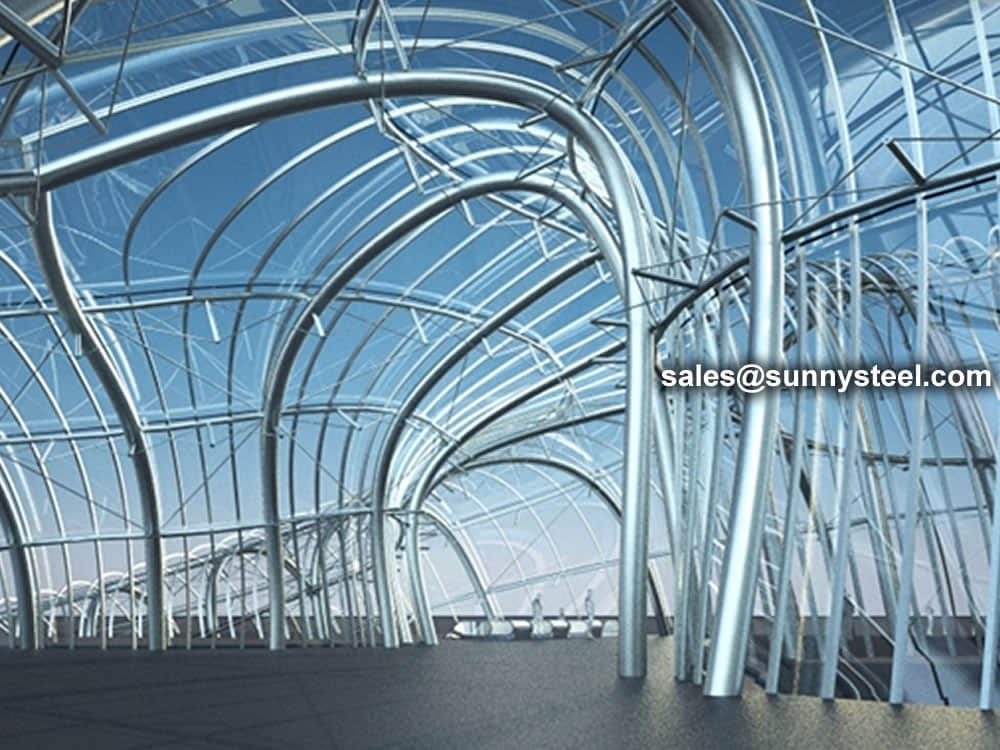

Structural steel pipes are commonly used in various construction and infrastructure projects due to their strength, durability, and versatility.

Structure Steel pipes are intended for mechanical and pressure applications and is also acceptable for ordinary uses in steam, water, gas, and air lines. With its enhanced cross-sectional efficiency, it makes a major contribution to lightweight, economic structural design. In addition, its attractive round appearance facilitates elegant and beautiful structures.

In general, structural pipe is a type of steel construction pipe that meets certain standards of chemical composition and mechanical properties. This pipe can be used for a wide variety of structural applications and there are variety of types of structural pipe available.

Structural steel pipes are an essential component in the construction and engineering industry. Known for their strength and durability, these pipes are used in a variety of applications, from building frameworks to supporting heavy machinery. This comprehensive guide will explore the various aspects of structural steel pipes, including their manufacturing process, material properties, applications, and the importance of quality control in ensuring their reliability.

The production of structural steel pipes involves several critical steps that ensure the final product meets the highest standards of quality and performance. The process begins with the selection of raw materials, which are typically high-quality steel billets. These billets undergo a series of heat treatments to improve their malleability and structural integrity.

Structural steel pipes are chosen for their superior material properties, which include high tensile strength, yield strength, and impact resistance. The chemical composition of these pipes is carefully controlled to achieve the desired balance of properties.

The versatility of structural steel pipes makes them suitable for a wide range of applications. In the construction industry, they are used as columns, beams, and purlins in building structures. In the oil and gas industry, they are used for pipelines and drilling equipment. They are also used in bridge construction, heavy machinery, and various engineering projects that require high-strength support structures.

Quality control is paramount in the production of structural steel pipes. Rigorous testing, including non-destructive testing (NDT) methods such as ultrasonic testing, radiographic testing, and magnetic particle inspection, ensures that the pipes are free from defects. Additionally, hydrostatic testing and pressure testing are conducted to verify the pipes' ability to withstand the stresses they will encounter in service.

Structural steel pipes are a critical component in many construction and engineering applications due to their strength, durability, and reliability. Understanding their manufacturing process, material properties, and the importance of quality control is essential for specifying the correct pipe for any given project. As the industry continues to evolve, the demand for high-quality structural steel pipes will remain a priority for ensuring the safety and longevity of infrastructure projects around the world.

Structural steel pipes are manufactured according to various standards and specifications, such as ASTM A500 and ASTM A513. These standards ensure the pipes' quality, dimensional accuracy, and mechanical properties.

ASTM A53 Standard Spec. for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and Seamless

ASTM A53 / A53M Standard covers seamless and welded black and hot-dipped galvanized steel pipe in NPS 1/8 to NPS 26.

Steel grade:

Application: for the manufacture of pipelines, containers, equipment, fittings and mechanical structures.

Steel pipe application in structure engineering is generated in the carbon steel smelting defect smelting and casting process, such as segregation, non-metallic inclusions, porosity, shrinkage and cracks.

| Product name | Manufacturing method | Main features and applications |

|---|---|---|

| Carbon Steel Pipe for Machine Structures | These products normally conform to JIS G 3445 Carbon Steel Tubes for Machine Structural Purposes. We also manufacture such carbon steel pipe products using materials that conform to JIS G 4051 Steel for Machine Structural Purposes, as well as to other standards and specifications. | These steel pipe products are used in machines, automobiles, bicycles, furniture, tools and utensils, and other machine parts. |

| Alloy Steel Pipe for Machine Structures | These products normally conform to JIS G 3441 Alloy Steel Tubes for Machine Structure Purposes, but we also manufacture such alloy steel pipe products using materials that conform to JIS G 4053 Low-Alloyed Steels for Machine Structural Use, as well as to other standards and specifications. | These steel pipe products are used in machines, automobiles, and other machine parts. |

| ERW Carbon Steel Pipe for Machine Structures | These products are manufactured based on JIS G 3472 Electric Resistance Welded Carbon Steel Tubes for Automobile Structural Purposes. | They are used mainly in automotive machine parts. |

| High-Strength Steel Pipe for Machine Structures | These steel pipe products, include seamless steel pipe, ERW steel pipe, and hot finished ERW steel pipe. | They are used in marine structures and cylinders for their excellent weldability and low-temperature properties, and in machine parts for reduced weight and increased strength. |

Tubes for structure are used for the manufacture of pipelines, vessels, equipment, pipe fittings, and steel structures.

Standard

| Usage | OD(mm) | WT(mm) | Steel Grade | Standard/ Specification | Aplication Fields |

|---|---|---|---|---|---|

| Structural Pipe | 42-760 | 4-120 | 20#,35#,45#,Q345A/B/C/D,Q390, Q420,25Mn,27SiMn etc. | GB/T 8162 | General structural and mechanical pipe |

| Vehicle Pipe | 45-245 | 4-35 | 20Mn2,SAE1527,MZ410R, MZ530R,30Mn2,40Cr,45Mn2 etc. | Technical agreement, YB/T5035 | Pipe used for automobile axle and automobile semi-shaft |

| Mold Pipe &Tube | DN200-DN1200 | 21CrMo10,21CrMo10-2 etc. | Q/OHAD030, technical agreement | Centrifugal graphite casting-iron pipe mold | |

| Military Pipe | 42-760 | 4-120 | 30Cr,40Cr,35CrNi1MoA etc. | National military standard, agreement | Pipe for military use |

| Geology Drilling Pipe &Tube | 42-133 | DZ40,DZ55,STM-R780,DZ60 etc. | Q/OHAD006, GB/T 9808, agreement | Drilling pipe | |

| Hydraulic Support Pipe | 42-760 | 4-120 | 20#,35#,45#,27SiMn,30MnNbRE, 30CrMnSi,30CrMnSiA etc. | GB/T 17396, technical agreement | Making hydraulic equipment for coal mine exploitation and hydraulic cylinder and piston for truck crane |

| Fluid Transmission Pipe & Tube | 42-760 | 4-120 | 20#,Q345,Q390 etc. | GB/T 8163, technical agreement | Pipe & tube used for fluid transmission |

| Abbr. | Corresponding | Application |

|---|---|---|

| A500 | ASTM A500 / A500M | Specification for Cold-Formed Welded and Seamless Carbon Steel Structural Tubing in Rounds and Shapes |

| A501 | ASTM A501 / A501M | Specification for Hot-Formed Welded and Seamless Carbon Steel Structural Tubing |

| A847 | ASTM A847 / A847M | Specification for Cold-Formed Welded and Seamless High Strength, Low Alloy Structural Tubing with Improved Atmospheric Corrosion Resistance |

| A618 | ASTM A618 / A618M | Specification for Hot-Formed Welded and Seamless High-Strength Low-Alloy Structural Tubing |

Nowadays, structural steel pipes are used in almost every sector. This material became immensely popular due to its durability, resistance power and load-bearing capacity. Experts use steel pipes in various fields such as manufacturing, structural and transportation.

The structural steel fabrication process involves combining various shapes to manufacture predefined sizes and shapes to assemble industrial tools, equipment and other products.

The different types of pipes used in building construction all have specific uses.

For example, some pipes may be practical for plumbing, while some kinds are more ideal for structural applications. When it comes to using these pipes for many installations, it’s important to consider the purpose, since this can be affected by the main piping material. Furthermore, the benefits of each type of pipe can bring about many advantages like cost-efficiency, versatility, environmental-friendliness, and the like.

One of the strongest and most durable pipe materials is carbon steel. As the name suggests, this type of pipe is characterised by a high carbon content. Carbon steel pipe can be further categorised according to how it is manufactured - i.e. seamless, ERW or welded (seamed).

Carbon steel pipe is an excellent choice for plumbing and other processes that require the transfer and conveyance of various types of fluids. It can be found in petrochemical plants, scaffolding, boiler systems, sewage and a wide range of industrial applications.

These pipes are fully capable of withstanding extreme temperature and pressure conditions. So if you're looking for high quality carbon steel tubing, make sure you only get it from Metal Exponents. Our carbon steel tubes come in a wide range of sizes and dimensions to suit any construction project or industrial application.

Cast iron pipe is probably one of the oldest types of pipe on the market. Given their toughness and durability, it's not surprising that many centuries-old waterways and sewers in European countries still use them today. In fact, a well-installed cast iron pipe system can last up to 100 years, provided it's properly maintained.

As well as sewerage and drainage systems, you'll also find cast iron pipes in high-rise buildings and other low-rise and residential buildings. They're particularly useful for storm drains, which can help prevent flooding and reduce water pollution for plumbing systems.

Despite their benefits, cast iron pipes are considered antiquated - you may not find these pipe materials in common use today as they tend to corrode and rust over time.

Steel pipes are also sometimes strengthened by a process called galvanisation. This technique adds anti-rust and anti-corrosion properties to the surface of the steel. This makes the steel last longer and more durable over time.

Although there are various galvanising techniques, hot-dip galvanising is the most commonly used method for steel pipes. The material must first undergo surface preparation before being immersed in a hot bath of molten zinc - at a temperature of around 500 degrees Celsius.

Once the galvanised steel pipe is ready for distribution and marketing, it can be used in a wide range of construction applications such as fencing, domestic water supplies, railings, drainage systems, bollards and even scaffolding. Although the initial cost of these pipes can be high, they're cost-effective in the long run because you can minimise maintenance and replacement costs.

And there's more! Galvanised iron pipes are also a great option for those looking for corrosion-resistant pipes. They can be found in both indoor and outdoor pipe installations, as they can withstand many forms of corrosion like rusting and pitting.

However, it's worth noting that they may not be the best choice for areas with high dissolved salt content, such as magnesium, iron, or calcium. While this may be expensive in the long run, the pipe will be worth it! All you have to do is make sure you keep it maintained to make sure it doesn't have these problems.

You'll find galvanised iron pipes everywhere! They're used in automotive, aerospace, architectural, agricultural, and telecommunications installations. They're affordable, yet incredibly sturdy.

Another fantastic option is the concrete pipe, which has been manufactured by crushing aggregates. While they may be more difficult to install than some of the other pipes on the list, they are well worth the effort! This type of pipe is extremely versatile and can be used in a wide range of applications. They are also extremely durable and can withstand a lot of wear and tear. Transporting them from one site to another is easy, and they are very easy to install.

Concrete pipes are extremely flexible and versatile despite their rigidity. They are suitable for use in drainage and sewage systems, and more commonly as culverts. And there’s more! These pipes are reinforced with other materials like steel to make them stronger and more protected against environmental damage.

PVC pipes are an excellent choice for many applications that require fluid transmission. They're lightweight, flexible, and versatile in design, making them ideal for a wide range of projects. You'll often find PVC pipes in electrical wiring systems, specifically as electrical conduit pipes. They provide a watertight and waterproof housing for electrical wires that may be exposed to external elements like high/low heat, pressure, and debris, which is great for keeping your wires safe!

However, they also have their disadvantages. To give an example: Their structuring can be easily warped and distorted in high-temperature environments, which can be difficult to avoid at times.