Alumina Ceramic Lined Components provide a durable, long-lasting solution for industries that handle abrasive and corrosive materials.

Download PDFAlumina Ceramic Lined Components are essential for industrial applications where high levels of wear, abrasion, and corrosion are present. These components are lined with alumina ceramic, which offers outstanding hardness and wear resistance. Widely used in industries such as mining, cement, power generation, steel, and chemical processing, alumina ceramic-lined components ensure a longer service life and reduced maintenance costs, even in the harshest working conditions.

Alumina ceramic lined components coated with alumina ceramics are characterized by high abrasion resistance even in combination with high operating temperature. So we use Alumina ceramic lined components when we have to convey very hot materials that give rise to significant wear.

Among other qualities of the alumina ceramic, we can also mention the remarkable regularity of its mechanical characteristics along the section, the high geometric regularity and the possibility to obtain very smooth surfaces.

The necessary raw materials and processes for production of alumina and manufacture of the component, which require expertise and a appropriate hardware, make these products more expensive than the equivalent with basalt coatings, compared with a duration far greater even thanks to an increased regularity of wear of the surface during operation.

Their exceptional wear resistance, impact strength, and ability to withstand high temperatures make them ideal for improving the efficiency and longevity of industrial equipment, while reducing maintenance and downtime. These components are a cost-effective choice for industries requiring robust and reliable protection from harsh operational environments.

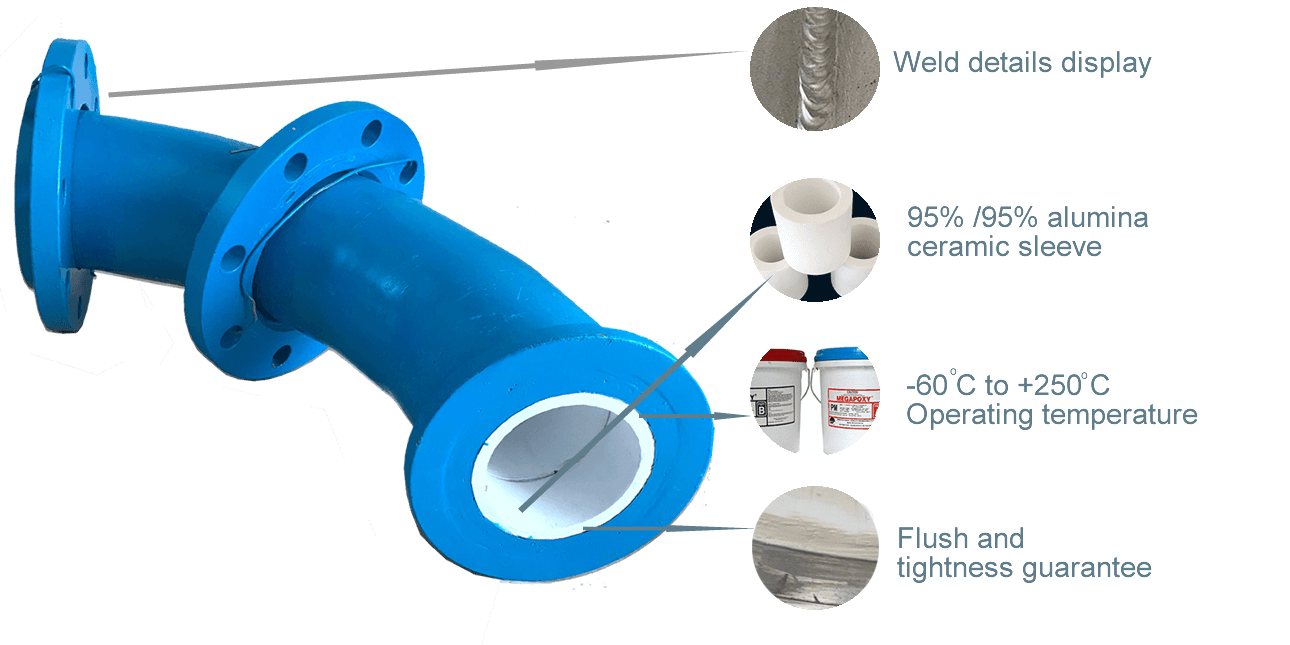

For different production environments, our company has developed a wear-resistant pipe for a variety of media, based on the temperature, wear and corrosion requirements of the field media, and for the initial application of the scene, our company to provide wear-resistant ceramic ring for the Lined composite straight pipe design to meet the on-site wear resistance, heat resistance and corrosion resistance requirements, in view of this program for the new design (formerly ceramic chip technology, there are many gaps, easy to wear).

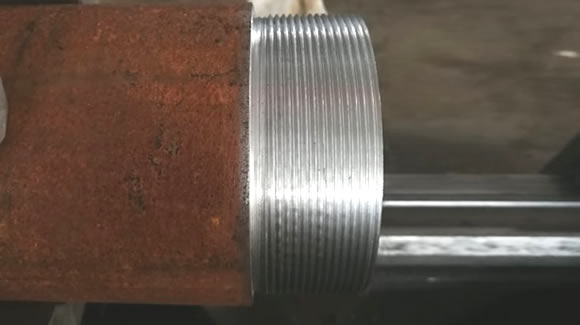

After the ceramic ring in the pipe is installed and the thread is processed, the dirt outside the pipe is cleaned, and the outer surface of the pipe is treated with three layers of anticorrosive paint to meet the export requirements.

| Item | Data | Characteristics of binder |

|---|---|---|

| Density (g/cm3) | 1.32 | We use the Australian Megapoxy high strength structural adhesive, this structural glue is modified epoxy resin polymer, anti-aging ability, and wear-resistant ceramic bonding to form a strong and cushion of the anti-wear layer, cured water, anti-corrosion performance is excellent, toughness, displacement-resistant effect is remarkable.

|

| Compressive strength (MPa) | 40 | |

| Shear Strength MPa | 26 | |

| Impact toughness Kj/m2 | 10 | |

| Hardness HB | 9.5 | |

| Elastic Modulus GPa | 2.2 | |

| Expansion coefficient 10-6/℃ | 20.1 | |

| Softening temperature℃ | 263 | |

| Coking temperature℃ | 335 | |

| Acid resistance(24H) | Stability | Test solution : 15%H2SO4 |

| Alkali resistance(24H) | Stability | Test solution: NaOH |