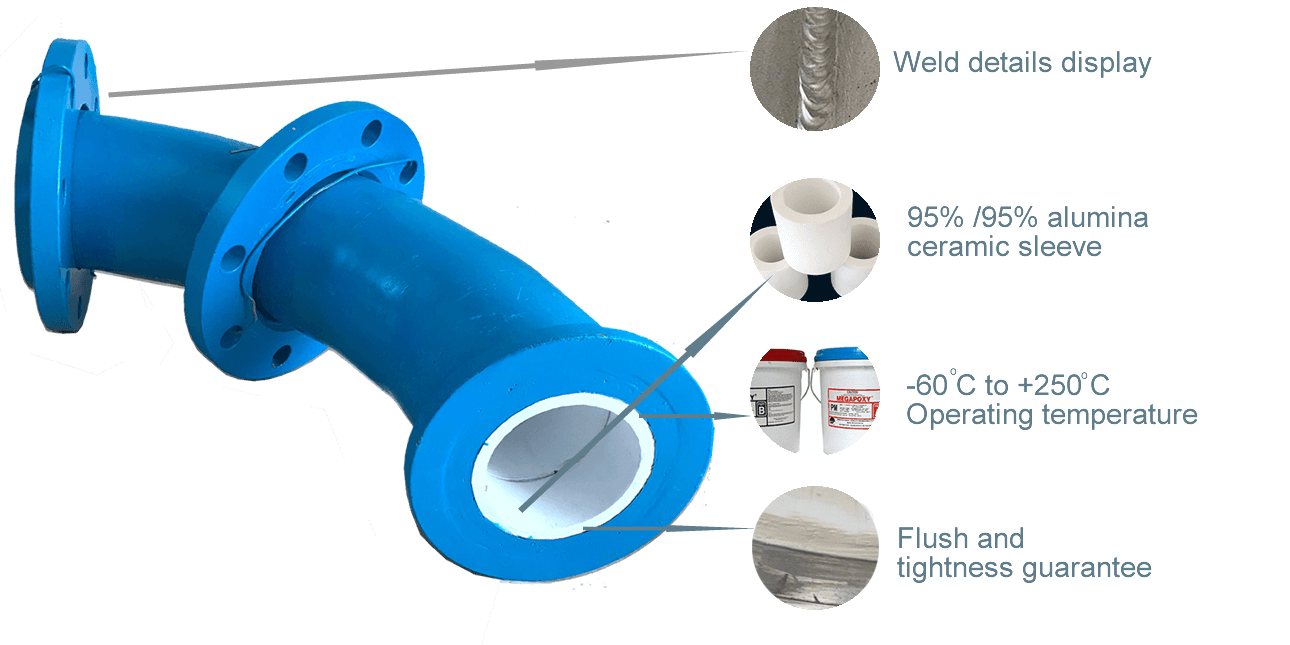

The Alumina ceramic sleeve lined pipe with flange as a whole part, and then assemble it into the steel pipe with our high-strength-temperature-resistant epoxy adhesive.

Download PDFA ceramic sleeve lined tee is a specialized pipe fitting that allows for the junction of three pipes while providing superior protection against wear and corrosion. Featuring a steel outer layer and a ceramic lining, this fitting is engineered to withstand the harsh conditions often encountered in industrial applications.

The Alumina ceramic sleeve lined pipe with flange as a whole part, and then assemble it into the steel pipe with our high-strength-temperature-resistant epoxy adhesive. The pipe consists of three layers: smooth ceramic lining (compact corundum), ceramic and metal transition layer and the outer steel pipe.

Ceramic sleeve lined tees represent a significant advancement in piping technology, offering exceptional wear resistance, corrosion protection, and improved flow efficiency. Their unique design makes them an excellent choice for a variety of industrial applications. As industries continue to face challenges from abrasive and corrosive environments, ceramic sleeve lined tees are set to enhance operational reliability and performance.

Ceramic sleeve lined tees are versatile and can be utilized in various sectors, including:

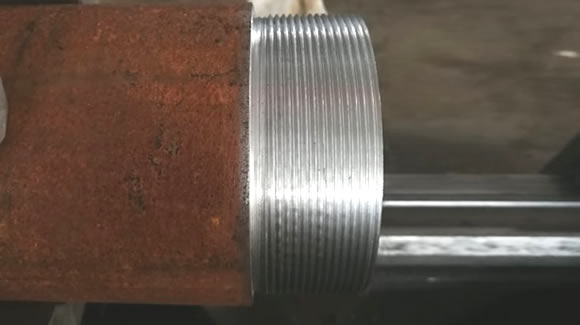

For different production environments, our company has developed a wear-resistant pipe for a variety of media, based on the temperature, wear and corrosion requirements of the field media, and for the initial application of the scene, our company to provide wear-resistant ceramic ring for the Lined composite straight pipe design to meet the on-site wear resistance, heat resistance and corrosion resistance requirements, in view of this program for the new design (formerly ceramic chip technology, there are many gaps, easy to wear).

After the ceramic ring in the pipe is installed and the thread is processed, the dirt outside the pipe is cleaned, and the outer surface of the pipe is treated with three layers of anticorrosive paint to meet the export requirements.

| Item | Data | Characteristics of binder |

|---|---|---|

| Density (g/cm3) | 1.32 | We use the Australian Megapoxy high strength structural adhesive, this structural glue is modified epoxy resin polymer, anti-aging ability, and wear-resistant ceramic bonding to form a strong and cushion of the anti-wear layer, cured water, anti-corrosion performance is excellent, toughness, displacement-resistant effect is remarkable.

|

| Compressive strength (MPa) | 40 | |

| Shear Strength MPa | 26 | |

| Impact toughness Kj/m2 | 10 | |

| Hardness HB | 9.5 | |

| Elastic Modulus GPa | 2.2 | |

| Expansion coefficient 10-6/℃ | 20.1 | |

| Softening temperature℃ | 263 | |

| Coking temperature℃ | 335 | |

| Acid resistance(24H) | Stability | Test solution : 15%H2SO4 |

| Alkali resistance(24H) | Stability | Test solution: NaOH |