Alumina ceramic lined pipe is a type of pipe that is lined with alumina ceramic, which is a high-performance material known for its exceptional hardness, wear resistance, and corrosion resistance.

Download PDFAlumina ceramic lined pipe is made by bonding alumina ceramic tiles or cylinders to the inner surface of the pipe using high-temperature adhesives or mechanical fittings.

The alumina ceramic lining provides excellent protection to the pipe against abrasion, erosion, and chemical attack. It is commonly used in industries that handle abrasive materials or corrosive substances, such as mining, cement, steel, power generation, and chemical processing.

Alumina ceramic lined pipes offer several advantages over conventional pipes. They can significantly extend the service life of the pipe by reducing wear and erosion, minimizing downtime, and lowering maintenance costs. The smooth surface and high hardness of the ceramic lining also contribute to improved flow efficiency and reduced pressure drop in the system.

Alumina ceramic lined pipes come in various sizes and configurations to suit different application requirements. They can be used in straight sections, elbows, tees, reducers, and other pipe fittings. The alumina ceramic lining can be customized to different thicknesses and shapes to provide optimal protection for specific operating conditions and material handling processes.

In summary, alumina ceramic lined pipes are a durable and reliable solution for industries that require high-performance piping systems to handle abrasive or corrosive materials. Their exceptional wear resistance, hardness, and corrosion resistance make them an ideal choice for demanding applications, offering long-lasting protection and improved system performance.

Our ceramic composite wear-resistant pipe is designed according to the customer requirement of steel pipe (Q235), the thickness of ceramic lining, and the inner diameter size of the final pipe. We use a special ceramic adhesion agent to laminate 92% pure alumina ceramic products to the inner wall of the steel pipe, thus forming a hard wear-resistant layer.

Alumina Ceramic Lined pipe is designed with an inner lining of alumina ceramic tiles that are highly resistant to abrasive wear, erosion, and corrosion. The lining is typically bonded directly to the steel pipe substrate using advanced adhesives that provide a strong and durable bond. This type of pipe offers superior wear and abrasion resistance over traditional piping materials such as steel or carbon. This makes Alumina Ceramic Lined pipe ideal for applications that require prolonged exposure to harsh environments and abrasive materials.

The high alumina ceramics are installed onto the internal surface of the pipe properly by welding, pasting or inter-locking system. With the brilliant properties of resistance to wear, corrosion and heat, the pipe is widely used in materials handing of coal industry, electric power, metallurgy, mining and chemical industry and it is one ideal wear resistant pipe.

1. Good wear resistance

The lining layer of the wear-resistant pipe is alumina ceramic, with Rockwell hardness up to 90 (HRA90 or more), which has high wear resistance to abrasive media delivered by metallurgy, electric power, mining, coal mining and other industries, and its life is more than ten times that of the quenching platform.

2. Anti-corrosion and anti-scaling

Since the ceramic layer is alumina ceramic, it has acid and alkali resistance, corrosion resistance and anti-scaling properties.

3. Good resistance to high temperature and thermal shock

It can be used in the range of -50℃ to 900℃ for a long time, and the coefficient of linear expansion is 6-8×10-6/℃, which is about 1/2 of steel pipe.

4. Easy installation and construction

Because of its small weight and good welding performance, it can be easily installed by welding and flange connection.

The composite wear-resistant pipes produced by our company have long life and high quality. It is widely used in metallurgy, iron and steel, coal, mining, thermal power, cement, chemical and other industries with serious equipment wear.

Thermal power plants: Ash removal, slag discharge pipes, powder feeding, powder returning pipes, and desulfurization pipes.

Metal mines: Conveying wear-resistant elbows for concentrates and tailings;

Metallurgy: Blast furnace coal injection and slag conveying pipes for iron making in iron and steel plants; CAO, zinc and sand conveying pipes, ferroalloy conveying in steel making, out-of-furnace refining and other preferred wear-resistant elbows;

Cement plant: Raw slurry transportation, pulverized coal transportation, hoist unloading, finished cement pneumatic transportation loading and unloading of rotary kiln wet production line, concrete transportation wear-resistant elbow.

Chemical plant: Coal powder conveying pipeline, silicon powder and other raw material conveying wear-resistant elbows.

Mine: Mine filling, concentrate powder and tailings transportation have serious wear and tear on the pipeline. The service life of the ore powder transportation pipeline used in the past, such as Daye Mine, is less than one year. Changing to this pipe can increase the service life by about 5 times.

Coal: Coal preparation and long-distance pipeline coal transportation generally adopt wet transportation, which requires the transportation pipe to be both wear-resistant and corrosion-resistant.

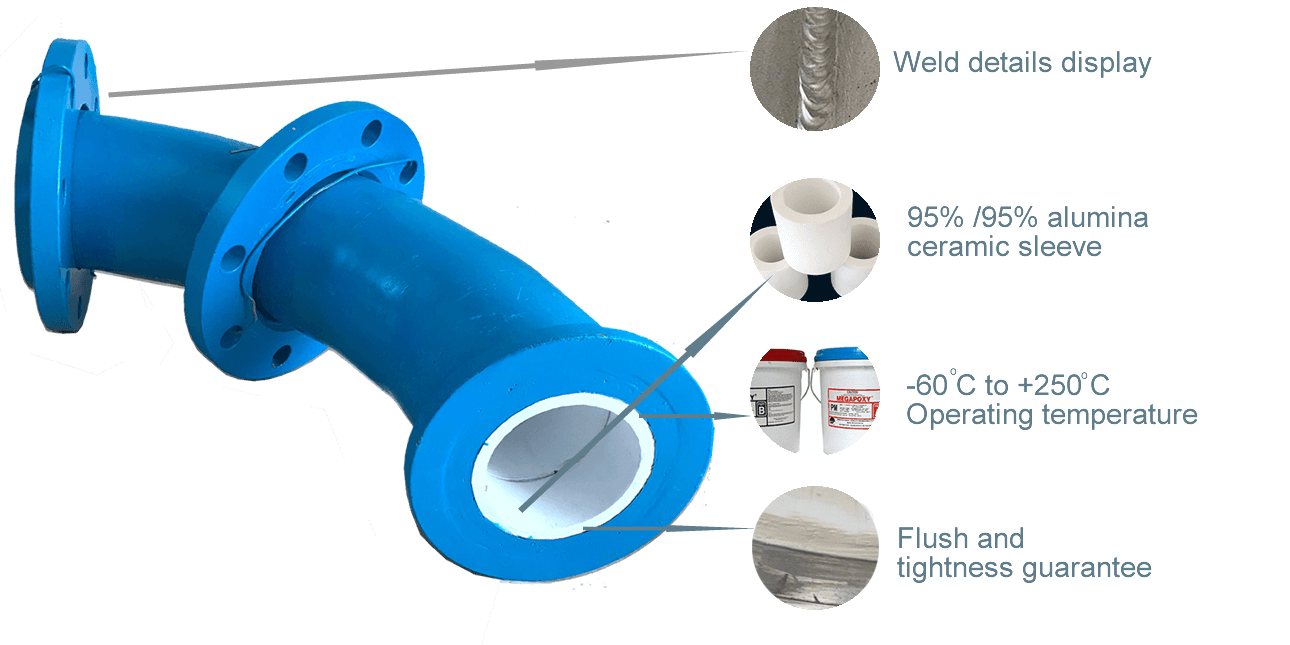

The main raw material of wear resistant ceramic ring is a special kind of ceramic with AL2O3 as the and the rare metal oxide as the flux, which is melted by high temperature at 1700 °C. The Ceramic Sleeves Lined Pipe as a whole part, and then assemble it into the steel pipe with our high-strength-temperature-resistant epoxy adhesive.

Recently 95% alumina ceramic sleeve lined pipes, elbows and T pipes have been largely applied in lithium battery material conveying system. The big diameter ceramic sleeve is always a big problem for the ceramic tube manufacturers since it’s very difficult to control the deformation rate of the ceramic sleeve after it’s sintering .Also It will also need an advanced and big isostatic pressing machine to do this .So it will not only express the company’s production capability ,but company’s technology. Right now, our factory have owned both advantages which are wear resistant ceramic pressing facilities and technologies.

Recently 95% alumina ceramic sleeve lined pipes, elbows and T pipes have been largely applied in lithium battery material conveying system.. The main raw material of wear resistant ceramic ring is a special kind of ceramic with AL2O3 as the and the rare metal oxide as the flux, which is melted by high temperature at 1700 °C. The big diameter ceramic sleeve is always a big problem for the ceramic tube manufacturers since it’s very difficult to control the deformation rate of the ceramic sleeve after it’s sintering .Also It will also need an advanced and big isostatic pressing machine to do this .So it will not only express the company’s production capability ,but company’s technology. Right now, our factory have owned both advantages which are wear resistant ceramic pressing facilities and technologies.

The wear resistant ceramic ring is a special kind of ceramic with Al2O3 as the main raw material and the rare metal oxide as the flux, which is melted by high temperature at 1700 oC.

Ceramic sleeve lined pipe has a continuous ceramic liner covering the inner surface of the pipe. The ceramic liner, or sleeve, is typically made of high-quality alumina ceramics, which provides excellent resistance to wear, abrasion and corrosion.

Ceramic sleeve lined pipes are commonly used in industrial applications where the pipeline is exposed to harsh conditions, such as in mining, power generation, oil and gas, and chemical processing. The ceramic sleeve provides superior wear resistance and protects the underlying steel pipe from premature failure due to abrasion or corrosion.

In addition to their excellent wear properties, ceramic sleeve lined pipes may also provide benefits such as improved flow rates, lower maintenance costs, and longer service life. They may also be used in applications where hygiene is important, as the ceramic sleeve lining is non-toxic and does not react with most chemicals.

Ceramic sleeve lined pipes may be manufactured in various sizes and shapes, including elbows, tees, and reducers, to meet the specific requirements of each application. The ceramic sleeve may be bonded to the steel pipe using specialized adhesives and may be installed using conventional welding or mechanical joining techniques.

While ceramic sleeve lined pipes can offer significant benefits in terms of wear resistance and longevity, they are typically more expensive than traditional steel pipes due to the cost of the ceramic liner and specialized manufacturing processes.

Ceramic pipe sleeves are a type of ceramic lining designed to protect metal, plastic or composite piping systems from wear and abrasion caused by high-velocity flows of abrasive materials. They are typically made of highly engineered ceramic materials such as alumina or silicon carbide, which provide excellent resistance to wear, corrosion, and erosion.

Ceramic pipe sleeves are widely used in industries such as mining, power generation, and chemical processing where the harsh environment can cause significant wear and damage to the piping systems.

The advantages of using ceramic pipe sleeves include:

Overall, ceramic pipe sleeves are an effective and reliable solution for protecting piping systems from the harsh effects of abrasive materials. They offer superior wear resistance, corrosion resistance, and improved efficiency compared to traditional materials, reducing maintenance costs and improving system performance.

| Items | 92% | 95% |

|---|---|---|

| Al2O3 | ≥92% | ≥95% |

| SiO2 | 0.0451 | 0.028 |

| Fe2O3 | 0.0001 | 0.0001 |

| TiO2 | 0.0005 | / |

| CaO | 0.018 | 0.0045 |

| MgO | 0.011 | 0.0051 |

| K2O | 0.0004 | 0.0003 |

| Na2O | 0.0031 | 0.0063 |

| Volume Density | 3.62 g/cm3 | 3.65 g/cm3 |

| Water Absorption (%) | ≤0.02% | ≤0.02% |

| POROSITY | ≤1 | ≤1 |

| Hardness | 9 Mohs | 9 Mohs |

| Flexural strength | ≥2000 Mpa | ≥2250 Mpa |

| Abrasion | ≤0.02 | ≤0.02 |

The combination of high rigidity of ceramic and high elasticity of steel gives the pipe unmatchable features as an abrasion resistant, heat resistant and corrosion resistant material for use in the fields of power generation, metallurgy, mining, and chemical industry etc. It has many advantages over steel pipes, cast stone pipes, and steel-plastic compound pipes.

| Data | Metric | Imperial |

|---|---|---|

| Tensile Strength, Ultimate | 655 MPa | 95 ksi |

| Tensile Strength, Yield | 290 MPa | 42 ksi |

| Elongation at Break (in 2") | 0.55 | 0.55 |

| Rockwell Hardness | B84 | B84 |

304 Stainless Steel Plate has very good formability and can be readily welded by all common methods.

Ceramic sleeve lined pipes are commonly used in industries such as mining, power generation, cement, steel, and chemical processing. They are particularly effective in applications where materials with high abrasiveness or corrosiveness need to be transported.

| Industry | Material |

|---|---|

| 1. Abrasive products | Grinding wheel granules |

| 2. Aluminium plants | Calcined alumina, bauxite, electrode, carbon, crushed bath |

| 3. Iron & Steel | Sinter dust, limestone, lime injection, coal, iron carbide, alloy additives |

| 4. Mineral wool & insulation products | Perlite, stone dust, refractory fibers, production wastes, dust from sawing operations |

| 5. Foundries | Molding sand, dust collection |

| 6. Glass plants | Batch, cullet, quartz, kaoline, feldspar |

| 7. Breweries, grain processing, feed mills | Corn, barley, soy beans, malt, cocoa beans, sunflower seeds, rice hulls, malting plants |

| 8. Cement | Clinker dust, limestone, cement, fly ash, coal, blast furnace slag |

| 9. Chemical plants | Caustic lime, fertilizers, lime dust, chrome ore, paint pigments, plastic pallets with glass fi bers |

| 10. Mineral mining plants | Kiln feed, ore concentrate, coal tailings, dust |

| 11. Coal fired power stations | Coal, fly ash, pyrites, slag, ash, limestone |

| 12. Coal mines | Coal dust, mine waste for backfi lling |

| 13. Technical carbon products | Technical carbon, dust, graphite for electrodes |

Abrasion resistant pipe using steel skeleton packaging, and the two ends of the pipe with plastic head, to prevent dust and rain into the pipeline inside, to ensure the beauty of the product.

For different production environments, our company has developed a wear-resistant pipe for a variety of media, based on the temperature, wear and corrosion requirements of the field media, and for the initial application of the scene, our company to provide wear-resistant ceramic ring for the Lined composite straight pipe design to meet the on-site wear resistance, heat resistance and corrosion resistance requirements, in view of this program for the new design (formerly ceramic chip technology, there are many gaps, easy to wear).

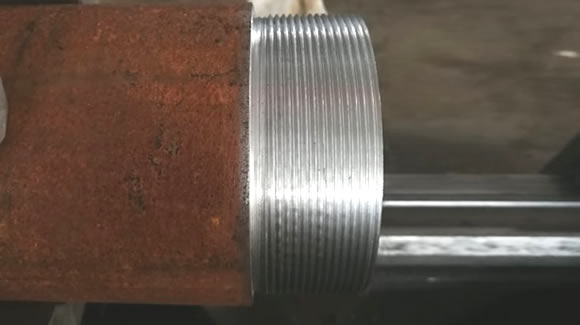

After the ceramic ring in the pipe is installed and the thread is processed, the dirt outside the pipe is cleaned, and the outer surface of the pipe is treated with three layers of anticorrosive paint to meet the export requirements.

| Item | Data | Characteristics of binder |

|---|---|---|

| Density (g/cm3) | 1.32 | We use the Australian Megapoxy high strength structural adhesive, this structural glue is modified epoxy resin polymer, anti-aging ability, and wear-resistant ceramic bonding to form a strong and cushion of the anti-wear layer, cured water, anti-corrosion performance is excellent, toughness, displacement-resistant effect is remarkable.

|

| Compressive strength (MPa) | 40 | |

| Shear Strength MPa | 26 | |

| Impact toughness Kj/m2 | 10 | |

| Hardness HB | 9.5 | |

| Elastic Modulus GPa | 2.2 | |

| Expansion coefficient 10-6/℃ | 20.1 | |

| Softening temperature℃ | 263 | |

| Coking temperature℃ | 335 | |

| Acid resistance(24H) | Stability | Test solution : 15%H2SO4 |

| Alkali resistance(24H) | Stability | Test solution: NaOH |