White 92% high ceramic alumina lined wear resistant bend pipe is made through self-propagating high-temperature synthesis (SHS) technique.

Download PDFWear resistant alumina ceramic rings are ceramic components specifically designed to withstand wear and abrasion in various industrial applications. These rings are made from alumina ceramic, which is known for its high hardness and wear resistance.

It's important to note that the specific design and dimensions of wear resistant alumina ceramic rings can vary depending on the application and requirements. Consulting with manufacturers or suppliers specializing in ceramic components is recommended to ensure the best fit for your specific needs.

| Industry | Material |

|---|---|

| 1. Abrasive products | Grinding wheel granules |

| 2. Aluminium plants | Calcined alumina, bauxite, electrode, carbon, crushed bath |

| 3. Iron & Steel | Sinter dust, limestone, lime injection, coal, iron carbide, alloy additives |

| 4. Mineral wool & insulation products | Perlite, stone dust, refractory fibers, production wastes, dust from sawing operations |

| 5. Foundries | Molding sand, dust collection |

| 6. Glass plants | Batch, cullet, quartz, kaoline, feldspar |

| 7. Breweries, grain processing, feed mills | Corn, barley, soy beans, malt, cocoa beans, sunflower seeds, rice hulls, malting plants |

| 8. Cement | Clinker dust, limestone, cement, fly ash, coal, blast furnace slag |

| 9. Chemical plants | Caustic lime, fertilizers, lime dust, chrome ore, paint pigments, plastic pallets with glass fi bers |

| 10. Mineral mining plants | Kiln feed, ore concentrate, coal tailings, dust |

| 11. Coal fired power stations | Coal, fly ash, pyrites, slag, ash, limestone |

| 12. Coal mines | Coal dust, mine waste for backfi lling |

| 13. Technical carbon products | Technical carbon, dust, graphite for electrodes |

Abrasion resistant pipe using steel skeleton packaging, and the two ends of the pipe with plastic head, to prevent dust and rain into the pipeline inside, to ensure the beauty of the product.

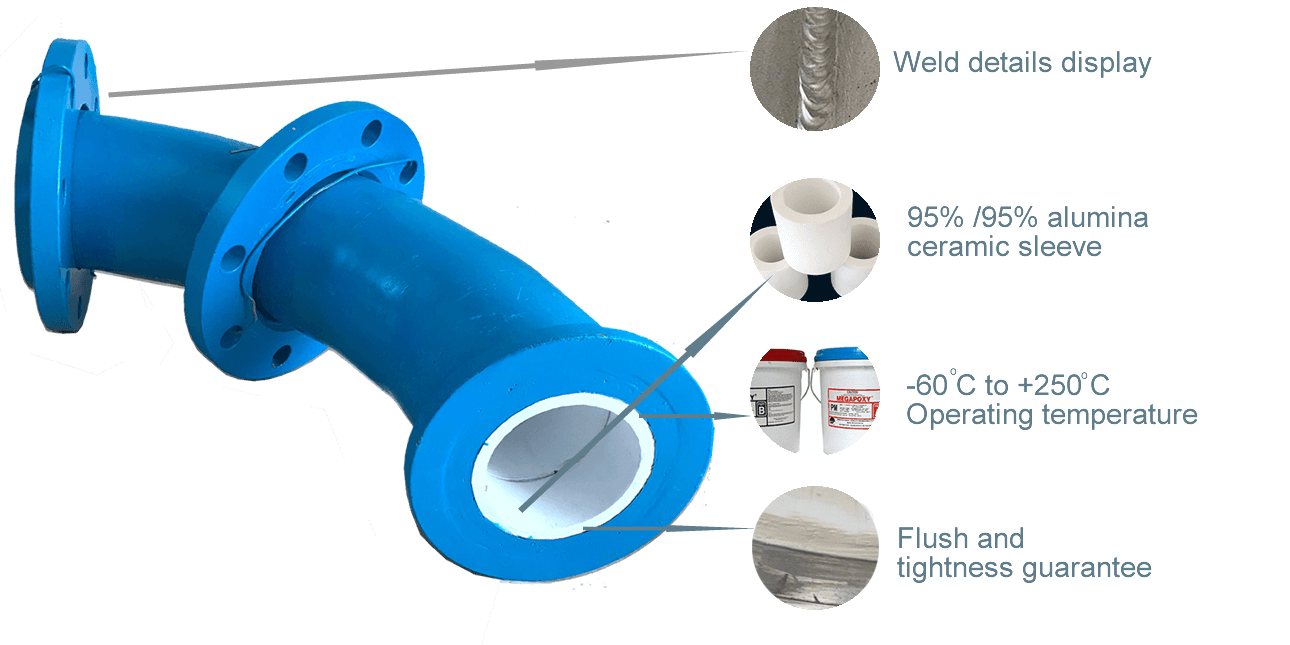

For different production environments, our company has developed a wear-resistant pipe for a variety of media, based on the temperature, wear and corrosion requirements of the field media, and for the initial application of the scene, our company to provide wear-resistant ceramic ring for the Lined composite straight pipe design to meet the on-site wear resistance, heat resistance and corrosion resistance requirements, in view of this program for the new design (formerly ceramic chip technology, there are many gaps, easy to wear).

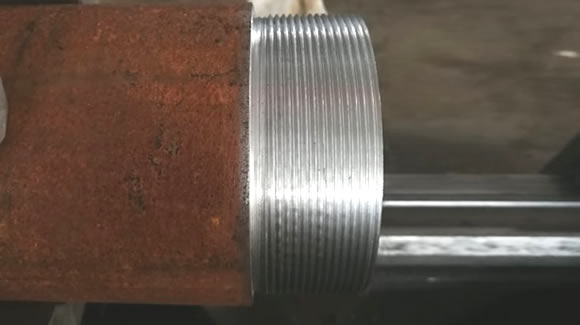

After the ceramic ring in the pipe is installed and the thread is processed, the dirt outside the pipe is cleaned, and the outer surface of the pipe is treated with three layers of anticorrosive paint to meet the export requirements.

| Item | Data | Characteristics of binder |

|---|---|---|

| Density (g/cm3) | 1.32 | We use the Australian Megapoxy high strength structural adhesive, this structural glue is modified epoxy resin polymer, anti-aging ability, and wear-resistant ceramic bonding to form a strong and cushion of the anti-wear layer, cured water, anti-corrosion performance is excellent, toughness, displacement-resistant effect is remarkable.

|

| Compressive strength (MPa) | 40 | |

| Shear Strength MPa | 26 | |

| Impact toughness Kj/m2 | 10 | |

| Hardness HB | 9.5 | |

| Elastic Modulus GPa | 2.2 | |

| Expansion coefficient 10-6/℃ | 20.1 | |

| Softening temperature℃ | 263 | |

| Coking temperature℃ | 335 | |

| Acid resistance(24H) | Stability | Test solution : 15%H2SO4 |

| Alkali resistance(24H) | Stability | Test solution: NaOH |