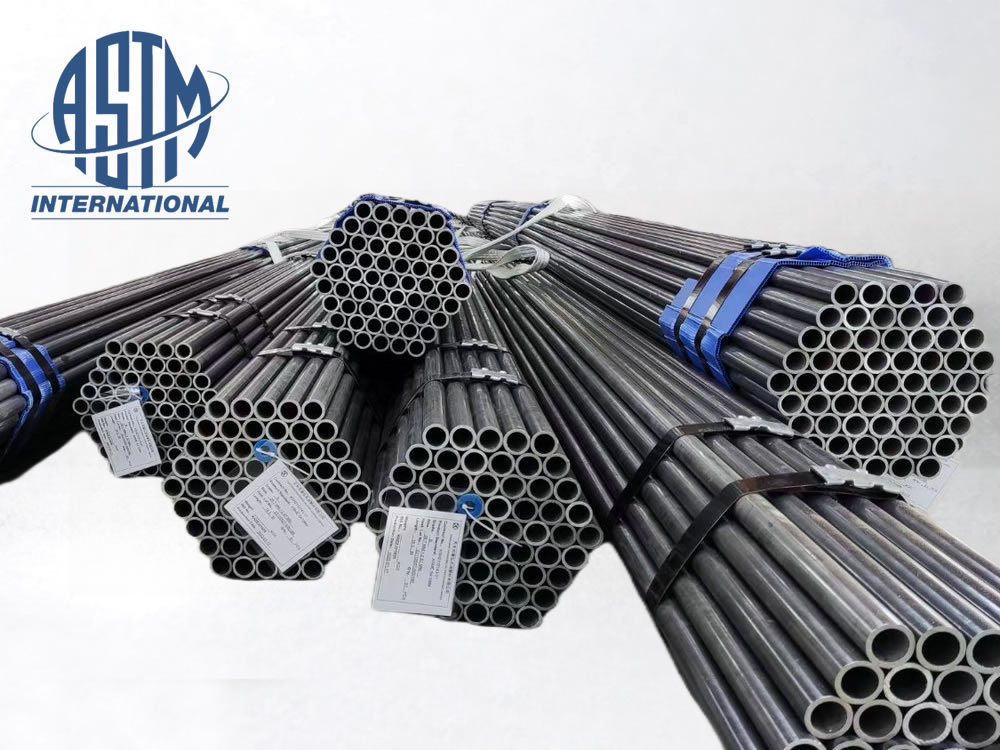

ASTM A53 Steel Pipe

ASTM A53 steel pipes are widely used for various industrial applications due to their strength and durability.

ASTM seamless pipes are high-quality pipes used extensively in industries for a variety of applications, particularly where high pressure, high temperature, and corrosion resistance are critical.

These pipes are manufactured according to the specifications set by the American Society for Testing and Materials (ASTM), which ensures their suitability for different industrial applications.

ASTM Standards can be purchased as a digital library subscription or individually from ASTM and other qualified standards providers.ASTM International has developed numerous standards for steel pipes, tubes, and fittings. These standards cover various aspects such as dimensions, materials, testing methods, and performance requirements. Some commonly referenced ASTM standards for steel pipes include ASTM A53/A53M, ASTM A106, ASTM A312/A312M, ASTM A789/A790, and ASTM A847. ASTM steel pipes are widely available from manufacturers, distributors, and suppliers worldwide. They come in different sizes, grades, and specifications to meet specific project requirements. It is important to consult with suppliers or refer to official sources to ensure the correct ASTM standard is selected for a particular application.

Our ASTM Specification pipe and tube are locally sourced, developed and produced which means our customers are assured of the highest quality standards and a local, concerned customer service presence invested in the success of your project We manufacture our tubular products at several Chinese based facilities that produce high-quality tubular products with low-residuals in a wide range of strength levels with superior toughness.

ASTM's steel standards are instrumental in classifying, evaluating, and specifying the material, chemical, mechanical, and metallurgical properties of the different types of steels, which are primarily used in the production of mechanical components, industrial parts, and construction elements, as well as other accessories related to them.

A pipe is a tubular section or hollow cylinder, usually but not necessarily of circular cross-section, used mainly to convey substances which can flow — liquids and gases (fluids), slurries, powders, masses of small solids. It can also be used for structural applications; hollow pipe is far stiffer per unit weight than solid members.

These steel standards are helpful in guiding metallurgical laboratories and refineries, product manufacturers, and other end-users of steel and its variants in their proper processing and application procedures to ensure quality towards safe use.

| Abbr. | Corresponding | Application |

|---|---|---|

| A53 | ASTM A53/A53m-99b | specification for pipe, steel, black and hot-dipped, zinc-coated, welded and seamless |

| A74 | ASTM A74-98 | specification for cast iron soil pipe and fittings |

| A106 | ASTM A106-99e1 | specification for seamless carbon steel pipe for high-temperature service |

| A126 | ASTM A126-95e1 | specification for grey iron castings for valves, flanges, and pipe fittings |

| A134 | ASTM A134-96 | specification for pipe, steel, electric-fusion (arc)-welded (sizes nps 16 and over |

| A135 | ASTM A135-97c | specification for electric-resistance-welded steel pipe |

| A139 | ASTM A139-96e1 | specification for electric-fusion (arc)-welded steel pipe (nps 4 and over) |

| A182 | ASTM A182/A182m-99 | specificationfor forged or rolled alloy-steel pipe flanges, forged fittings, and valves and parts for high-temperature service |

| A252 | ASTM A252-98 | specification for welded and seamless steel pipe piles |

| A312 | ASTM A312/a312m-00 | specification for seamless and welded austenitic stainless steel pipes |

| A333 | ASTM A333/A333m-99 | specification for seamless and welded steel pipe for low-temperature service |

| A335 | ASTM A335/A335m-99 | specification for seamless ferritic alloy-steel pipe for high-temperature service |

| A338 | ASTM A338-84(1998) | specificationfor malleable iron flanges, pipe fittings, and valve parts for railroad, marine, and other heavy duty service at temperatures up to 650°f (345°c) |

| A358 | ASTM A358/A358m-98 | specification for electric-fusion-welded austenitic chromium-nickel alloy steel pipe for high-temperature service |

| A369 | ASTM A369/A369m-92 | specification for carbon and ferritic alloy steel forged and bored pipe for high-temperature service |

| A376 | A376/A376m-98 | specification for seamless austenitic steel pipe for high-temperature central-station service |

| A377 | ASTM A377-99 | index of specifications for ductile-iron pressure pipe |

| A409 | ASTM A409/A409m-95ae1 | specification for welded large diameter austenitic steel pipe for corrosive or high-temperature service |

| A426 | ASTM A426-92(1997) | specification for centrifugally cast ferritic alloy steel pipe for high-temperature service |

| A451 | ASTM A451-93(1997) | specification for centrifugally cast austenitic steel pipe for high-temperature service |

| A523 | ASTM A523-96 | specification for plain end seamless and electric-resistance-welded steel pipe for high-pressure pipe-type cable circuits |

| A524 | ASTM A524-96 | specification for seamless carbon steel pipe for atmospheric and lower temperatures |

| A530 | ASTM A530/A530m-99 | specification for general requirements for specialized carbon and alloy steel pipe |

| A648 | ASTM A648-95e1 | specification for steel wire, hard drawn for prestressing concrete pipe |

| A674 | ASTM A674-95 | practice for polyethylene encasement for ductile iron pipe for water or other liquids |

| A691 | ASTM A691-98 | specification for carbon and alloy steel pipe, electric-fusion-welded for high-pressure service at high temperatures |

| A694 | ASTM A694/A694m-00 | specification for carbon and alloy steel forgings for pipe flanges, fittings, valves, and parts for high-pressure transmission service |

| A716 | ASTM A716-99 | specification for ductile iron culvert pipe |

| A733 | ASTM A733-99 | specification for welded and seamless carbon steel and austenitic stainless steel pipe nipples |

| A742 | ASTM A742/A742m-98 | specification for steel sheet, metallic coated and polymer precoated for corrugated steel pipe |

| A746 | ASTM A746-99 | specification for ductile iron gravity sewer pipe |

| A760 | ASTM A760/A760m-99 | specification for corrugated steel pipe, metallic-coated for sewers and drains |

| a761 | ASTM A761/A761m-98 | specification for corrugated steel structural plate, zinc-coated, for field-bolted pipe, pipe-arches, and arches |

| A762 | ASTM A762/A762m-98 | specification for corrugated steel pipe, polymer precoated for sewers and drains |

| A790 | ASTM A790/A790m-99 | specification for seamless and welded ferritic/austenitic stainless steel pipe |

| A796 | ASTM A796/A796m-99 | practice for structural design of corrugated steel pipe, pipe-arches, and arches for storm and sanitary sewers and other buried applications |

| A798 | ASTM A798/A798m-97a | practice for installing factory-made corrugated steel pipe for sewers and other applications |

| A807 | ASTM A807/A807m-97 | practice for installing corrugated steel structural plate pipe for sewers and other applications |

| A810 | ASTM A810-94 | specification for zinc-coated (galvanized) steel pipe winding mesh |

| A813 | ASTM A813/A813m-95e2 | specification for single- or double-welded austenitic stainless steel pipe |

| A814 | ASTM A814/A814m-96 (1998) | specification for cold-worked welded austenitic stainless steel pipe |

| A849 | ASTM A849-99 | specification for post-applied coatings, pavings, and linings for corrugated steel sewer and drainage pipe |

| A861 | ASTM A861-94e1 | specification for high-silicon iron pipe and fittings |

| A862 | ASTM A862/A862m-98 | practice for application of asphalt coatings to corrugated steel sewer and drainage pipe |

| A865 | ASTM A865-97 | specification for threaded couplings, steel, black or zinc-coated (galvanized) welded or seamless, for use in steel pipe joints |

| A872 | ASTM A872-91 (1997) | specification for centrifugally cast ferritic/austenitic stainless steel pipe for corrosive environments |

| A885 | ASTM A885/A885m-96 | specification for steel sheet, zinc and aramid fiber composite coated for corrugated steel sewer, culvert, and underdrain pipe |

| A888 | ASTM A888-98e1 | specification for hubless cast iron soil pipe and fittings for sanitary and storm drain, waste, and vent piping applications |

| A926 | ASTM A926-97 | test method for comparing the abrasion resistance of coating materials for corrugated metal pipe |

| A928 | ASTM A928/A928m-98 | specification for ferritic/austenitic (duplex) stainless steel pipe electric fusion welded with addition of filler metal |

| A929 | ASTM A929/A929m-97 | specification for steel sheet, metallic-coated by the hot-dip process for corrugated steel pipe |

| A930 | ASTM A930-99 | practice for life-cycle cost analysis of corrugated metal pipe used for culverts, storm sewers, and other buried conduits |

| A943 | ASTM A943/A943m-95e1 | specification for spray-formed seamless austenitic stainless steel pipes |

| A949 | ASTM A949/A949m-95e1 | specification for spray-formed seamless ferritic/austenitic stainless steel pipe |

| A954 | ASTM A954-96 | specification for austenitic chromium-nickel-silicon alloy steel seamless and welded pipe |

| A972 | ASTM A972/A972m-99 | specification for fusion bonded epoxy-coated pipe piles |

| A978 | ASTM A978/A978m-97 | specification for composite ribbed steel pipe, precoated and polyethylene lined for gravity flow sanitary sewers, storm sewers, and other special applications |

| A984 | ASTM A984/A984m-00 | specification for steel line pipe, black, plain-end, electric-resistance-welded |

| A998 | ASTM A998/A998m-98 | practice for structural design of reinforcements for fittings in factory-made corrugated steel pipe for sewers and other applications |

| A999 | A999/A999m-98 | specification for general requirements for alloy and stainless steel pipe |

| A1005 | ASTM A1005/A1005m-00 | specification for steel line pipe, black, plain end, longitudinal and helical seam, double submerged-arc welded |

| A1006 | ASTM A1006/A1006m | specification for steel line pipe, black, plain end, laser beam welded |

| Abbr. | Corresponding | Application |

| A179 | ASTM A179 / A179M | Standard Specification for Seamless Cold-Drawn Low-Carbon Steel Heat-Exchanger and Condenser Tubes |

| A213 | ASTM A213/A213M | Specification for Seamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater, and Heat-Exchanger Tubes |

| A214 | ASTM A214 / A214M | Specification for Electric-Resistance-Welded Carbon Steel Heat-Exchanger and Condenser Tubes |

| A249 | ASTM A249 / A249M | Specification for Welded Austenitic Steel Boiler, Superheater, Heat-Exchanger, and Condenser Tubes |

| A498 | ASTM A498 / A498M | Specification for Seamless and Welded Carbon, Ferritic, and Austenitic Alloy Steel Heat-Exchanger Tubes with Integral Fins |

| A851 | ASTM A851 / ASME SA851 | Specification for High-Frequency Induction Welded, Unannealed, Austenitic Steel Condenser Tubes |

| Abbr. | Corresponding | Application |

| A511 | ASTM A511 / A511M | Specification for Seamless Stainless Steel Mechanical Tubing |

| A512 | ASTM A512 / ASME SA512 | Specification for Cold-Drawn Buttweld Carbon Steel Mechanical Tubing |

| A513 | ASTM A513 / A513M | Specification for Electric-Resistance-Welded Carbon and Alloy Steel Mechanical Tubing |

| A519 | ASTM A519 / A519M | Specification for Seamless Carbon and Alloy Steel Mechanical Tubing |

| A554 | ASTM A554 | Specification for Welded Stainless Steel Mechanical Tubing |

| Abbr. | Corresponding | Application |

|---|---|---|

| A500 | ASTM A500 / A500M | Specification for Cold-Formed Welded and Seamless Carbon Steel Structural Tubing in Rounds and Shapes |

| A501 | ASTM A501 / A501M | Specification for Hot-Formed Welded and Seamless Carbon Steel Structural Tubing |

| A847 | ASTM A847 / A847M | Specification for Cold-Formed Welded and Seamless High Strength, Low Alloy Structural Tubing with Improved Atmospheric Corrosion Resistance |

| A618 | ASTM A618 / A618M | Specification for Hot-Formed Welded and Seamless High-Strength Low-Alloy Structural Tubing |

| Abbr. | Corresponding | Application |

|---|---|---|

| A234 | ASTM A234 / A234M | Specification for Piping Fittings of Wrought Carbon Steel and Alloy Steel for Moderate and High Temperature Service |

| A403 | ASTM A403/A403M | Specification for Wrought Austenitic Stainless Steel Piping Fittings |

| A420 | ASTM A420 / A420M | Specification for Piping Fittings of Wrought Carbon Steel and Alloy Steel for Low-Temperature Service |

| A774 | ASTM A774 / A774M | Specification for As-Welded Wrought Austenitic Stainless Steel Fittings for General Corrosive Service at Low and Moderate Temperatures |

| A758 | ASTM A758 / A758M | Specification for Wrought-Carbon Steel Butt-Welding Piping Fittings with Improved Notch Toughness |

Engineering specification is also a language, and standard specifications for material and processes are defined differently in each country in the world. To a new designer, steel grades might seem easy, where 316 stainless steel is one material and cast iron another, but there are variations in each of these categories of metal. Rumors abound about people receiving poor quality steels from other jurisdictions. It leaves some designers wondering if there is something intrinsic in the official standards in other countries that can lead to these complaints.

International standards do not translate, metal-for-metal, the way words might translate. When converting from one standard to another, it’s almost impossible to find identical compositions for a given type of metal. The question becomes: can you find an equivalent? This can be confusing, as each named metal grade has its own chemistry and production guidelines.

For people without a materials background, these differences can make the purchase of foreign-made metal seem iffy, like ordering an inferior knockoff. However, the quality of the grades of steel are as good, country to country. Understanding what makes a steel standard or specification can help a North American business navigate overseas production.

Metal alloys are a mixture of different proportions of elements. A standard includes the chemistry, or “recipe” for the alloy, documenting what different elements should be melted into it. Specific instructions may also be given on melting temperature, cooling, and treatment.

Published standards also record the mechanical properties of a specified metal. If it has been made correctly, a metal should not only have the correct chemical analysis, but also perform within the correct range in mechanical tests.

Steels contain iron and carbon. Standards for each grade of steel specify the proportions by weight of each of these elements, as well as any additional elements alloyed with them. These additions may create different characteristics: for example, chromium is present in stainless steel to help prevent rusting.

In most consumer metal standards, the proportions of each element are given an acceptable range, rather than a precise number. For example, the ASTM 1050 grade steel is so named because it is approximately .50% carbon by weight. However, the tolerance for carbon percentage in the ASTM 1050 standard is .48-.55%. A similar Japanese specification sets carbon between .47-.53%, and allows for silicon and other trace elements, whereas the ASTM standard does not.

Steel specifications often provide ranges for carbon, manganese, silicon, phosphorus, sulfur, chromium, nickel, and molybdenum, and none set identical ranges for each element. It is for this reason that steel standards from different organizations are not precise matches: the tolerances merely overlap. If one steel specifies less than .007% sulfur content, and another allows up to .040%, are they different steels? Small changes do not matter in many situations but may be relevant depending on the metal’s intended use.

It is not just chemistry, but also processing, that changes the behavior of a metal. Metal is crystalline and forms grain microstructures as it cools. Chemistry, melting, cooling, and heat treatment all can change the grain of the metal. This directly influences tensile strength, hardness, and brittleness. Therefore, steel specification may also include the production steps needed to create particular microstructures, including martensite, austenite, or ferrite grains.

When making a substitution between one standard and another, a skilled metallurgist or engineer will evaluate comparable grades based on mechanical properties. The engineer considers what the final product needs to do, and in what conditions. Using their understanding of chemistry, the expected working load, and knowledge of the conditions the product will work in, they can find a steel for the product’s requirements in any standard. All recognized steel standards generally have equivalent rigor, making this translation possible.

It is not a difference in published standards that are the source of poor-quality foreign metals.

With years of expertise, we provide a diverse array of steel tube processing options. From sawing and machining tube blanks to intricate bending and upsetting operations, we actively assist you throughout your projects.

Our capabilities extend to eccentricity reduction and concentricity enhancement through turning and grinding. We excel in creating complex geometries using processes like rotary swaging and axial forming. Additionally, we offer property modifications via partial heat treatment, ensuring tailored solutions for your specific needs.

Seamless steel pipe is regularly used in the transportation of fluids such as water, natural gas, waste and air. It is also regularly required in many high-pressure, high-corrosive environments such as in the oil & gas, power generation and pharmaceutical industries. Some common uses of seamless pipes include:

Commonly used alloying elements and their effects are listed in the table given below.

| Alloying Elements | Effect on the Properties |

|---|---|

| Chromium | Increases Resistance to corrosion and oxidation. Increases hardenability and wear resistance. Increases high temperature strength. |

| Nickel | Increases hardenability. Improves toughness. Increases impact strength at low temperatures. |

| Molybdenum | Increases hardenability, high temperature hardness, and wear resistance. Enhances the effects of other alloying elements. Eliminate temper brittleness in steels. Increases high temperature strength. |

| Manganese | Increases hardenability. Combines with sulfur to reduce its adverse effects. |

| Vanadium | Increases hardenability, high temperature hardness, and wear resistance. Improves fatigue resistance. |

| Titanium | Strongest carbide former. Added to stainless steel to prevent precipitation of chromium carbide. |

| Silicon | Removes oxygen in steel making. Improves toughness. Increases hardness ability |

| Boron | Increases hardenability. Produces fine grain size. |

| Aluminum | Forms nitride in nitriding steels. Produces fine grain size in casting. Removes oxygen in steel melting. |

| Cobalt | Increases heat and wear resistance. |

| Tungsten | Increases hardness at elevated temperatures. Refines grain size. |