Bearing Pipes

Pipes designed for bearing loads, offering high strength and durability.

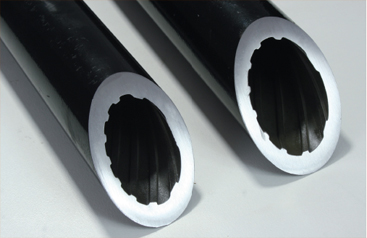

Multi-rifled seamless steel tubes are used in various applications, particularly in high-pressure boilers and heat exchangers.

Multi-rifled seamless steel tube is used as a water wall tube loaded with a highly heated flux and is also expected to find broadened other uses in the viewpoint of iits energy saving effect and higher safety against the overheating damage. This has groove on its inside surface which functions to raise thermal efficiency by distrubing the fluid within the tube, featuring and extremely high thermal conduction property.

The tubes may adhere to various standards, such as GB/T 20409, ASME SA-210M-2015, and ISO 9001. Compliance with these standards ensures the quality and performance of the tubes.

Multi-rifled seamless steel tube are produced to meet specific end use requirements, specifications, tolerances and chemistries.

| Grade | O.D.(mm) | W.T.(mm) | Number of rib |

|---|---|---|---|

| 20G 15CrMoG SA-210A1 SA-210C SA-213 T2 SA-213 T12 |

22-83 | 4.5-13 | 4-14 |

| Material (Grade) | C | Mn | Si | Cr | Mo | S | P |

|---|---|---|---|---|---|---|---|

| 20G | 0.17~0.23 | 0.35~0.65 | 0.17~0.37 | --- | --- | ≤0.020 | ≤0.025 |

| 20MnG | 0.17~0.23 | 0.70~1.00 | 0.17~0.37 | --- | --- | ≤0.020 | ≤0.025 |

| 25MnG | 0.22~0.29 | 0.70~1.00 | 0.17~0.37 | --- | --- | ≤0.020 | ≤0.025 |

| 12CrMoG | 0.08~0.15 | 0.40~0.70 | 0.17~0.37 | 0.40~0.70 | 0.40~0.55 | ≤0.020 | ≤0.025 |

| 15CrMoG | 0.12~0.18 | 0.40~0.70 | 0.17~0.37 | 0.80~1.10 | 0.40~0.55 | ≤0.020 | ≤0.025 |

| SA-210A1 | ≤0.27 | ≤0.93 | ≥0.10 | --- | --- | ≤0.035 | ≤0.035 |

| SA-210C | ≤0.35 | 0.29~1.06 | ≥0.10 | --- | --- | ≤0.035 | ≤0.035 |

| SA-213T2 | 0.10~0.20 | 0.30~0.61 | 0.10~0.30 | 0.50~0.81 | 0.44~0.65 | ≤0.025 | ≤0.025 |

| SA-213T12 | 0.05~0.15 | 0.30~0.61 | ≤0.50 | 0.80~1.25 | 0.44~0.65 | ≤0.025 | ≤0.025 |

| Material (Grade) | Tensile strength (MPa) | Yield strength (MPa) | Elongation(%) | Hardness |

|---|---|---|---|---|

| 20G | 410~550 | 245 | ≥24 | --- |

| 20MnG | ≥415 | ≥240 | ≥22 | --- |

| 25MnG | ≥485 | ≥275 | ≥20 | --- |

| 12CrMoG | 410~560 | ≥205 | ≥21 | --- |

| 15CrMoG | 440~640 | ≥235 | ≥21 | --- |

| SA-210C | ≥415 | ≥255 | ≥30 | ≤143HBW |

| SA-210A1 | ≥485 | ≥275 | ≥30 | ≤179HBW |

| SA-213T2 | ≥415 | ≥205 | ≥30 | ≤163HBW |

| SA-213T12 | ≥415 | ≥220 | ≥30 | ≤163HBW |

| Material (Grade) | Heat treatment |

|---|---|

| 20G | Normalizing at 900℃~930℃, the holding time is 1min/mm according to the wall thickness, but should not be less than 12min. |

| 20MnG | Normalizing at 900℃~930℃, the holding time is 1min/mm according to the wall thickness, but should not be less than 12min. |

| 25MnG | Normalizing at 900℃~930℃, the holding time is 1min/mm according to the wall thickness, but should not be less than 12min. |

| 12CrMoG | 900°C~930°C normalizing; 670°C~720°C tempering, holding time: Periodic furnace is more than 2h, continuous furnace is more than 1h. |

| 15CrMoG | Normalizing at 930°C~960°C; tempering at 680°C~720°C, holding time: periodic furnace greater than 2h, continuous furnace greater than 1h. |

We manufacture tubes in every possible boiler grade steels. All our steel is melted in-house through electric arc furnace route, than is ladle refined, 100% vacuum degassed, continuous cast and rolled.

Rifled tubes used in furnace power plants and other facilities with high temperature and pressure that are used to prevent film boiling.

The rifled tube is used as a water wall tube loaded with a highly heated flux and is also expected to find broadened other uses in the viewpoint of its energy-saving effect and higher safety against overheating damage.

The rifled tube has a groove on its inside surface that functions to raise thermal efficiency by disturbing the fluid within the tube, featuring an extremely high thermal conduction property.

Inside the water wall pipes of boilers in sub-critical steam power plants, water boils into steam vapor. Inside high temperature/high pressure boiler devices, a special type of boiling called film boiling occurs. The boundary between the fluid and water wall pipe forms a layer of steam. When film boiling occurs, the heat transfer efficiency is reduced due to the steam layer. Since heat cannot be effectively transferred from the pipe to the water, the pipe temperature rise can cause boiling explosions due to overheating, resulting in facility damage. A rifled tube contains multiple butterfly ribs on the inner surface of the steel pipe, whisking the water inside and causing turbulence that suppresses film boiling. Multiple ribs greatly increase the internal surface area of the pipe compared to rib-less steel pipes, resulting in increased boiler energy output efficiency. Internally ribbed tubing helps to decrease mass flow and ensures sufficient cooling for the internal surfaces of tubes.

All our steel is melted in-house through electric arc furnace route, than is ladle refined, 100% vacuum degassed, continuous cast and rolled.

Multi-Lead Rifled Seamless Tube is a seamless steel tube with thread-like channels rolled on the inner surface of the boiler evaporation heating surface.

Multi-Lead Rifled Seamless Tube is mostly used in the manufacture of boiler wall water-cooled wall tubes. It is the main heat exchange component of power station boilers. It rotates the water in the tube through the spiral ribs on the inner wall of the tube, thereby destroying the heat transfer process. Membrane effect to achieve the effect of nucleate boiling.

Multi-Lead Rifled Seamless Tube is divided into ordinary Rifled Seamless Tube and optimized Rifled Seamless Tube. Ordinary internal threaded pipe is divided into A type and B type, the helix angle is 30°, which can improve the heat transfer efficiency by 30% compared with ordinary round pipe.

As described above the heat transfer rate can be optimized by varying the rifling geometry based on operation conditions. In addition to the standard rifle tubes (covered in this brochure), SunnySteel manufactures rifled tubes to suit any customized geometry and in all boiler steel grades. We regularly manufacture and deliver such customized solutions at short notice.

Seamless steel pipe is regularly used in the transportation of fluids such as water, natural gas, waste and air. It is also regularly required in many high-pressure, high-corrosive environments such as in the oil & gas, power generation and pharmaceutical industries. Some common uses of seamless pipes include:

Chemical composition inspection, mechanical properties test(tensile strength,yield strength, elongation, flaring, flattening, bending, hardness, impact test), surface and dimension test,no-destructive test, hydrostatic test.

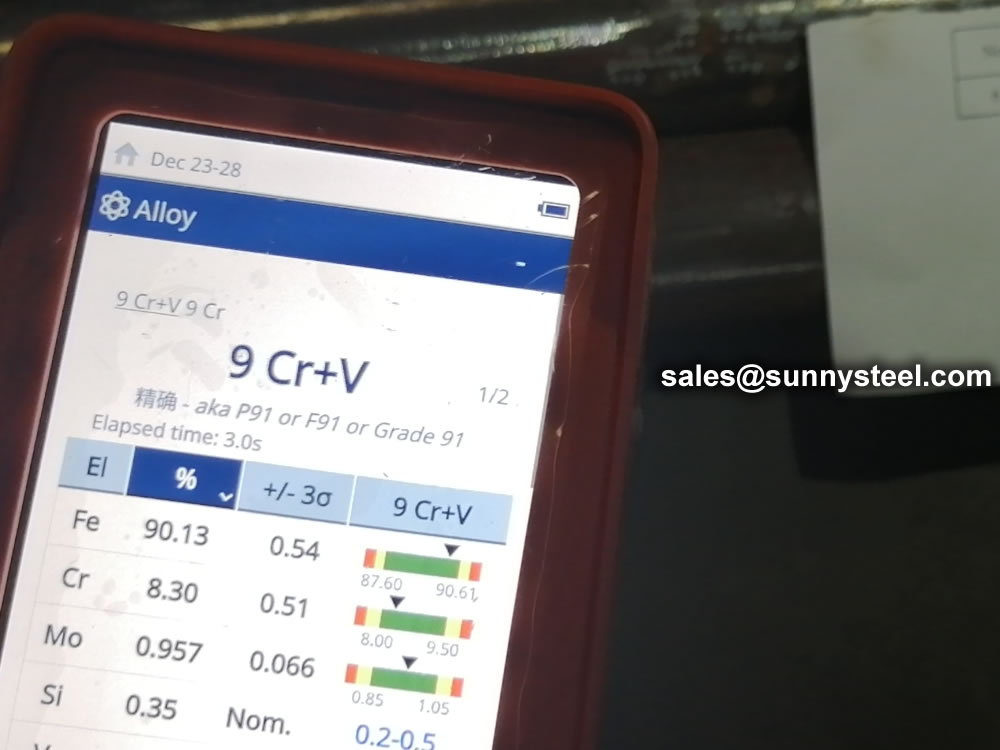

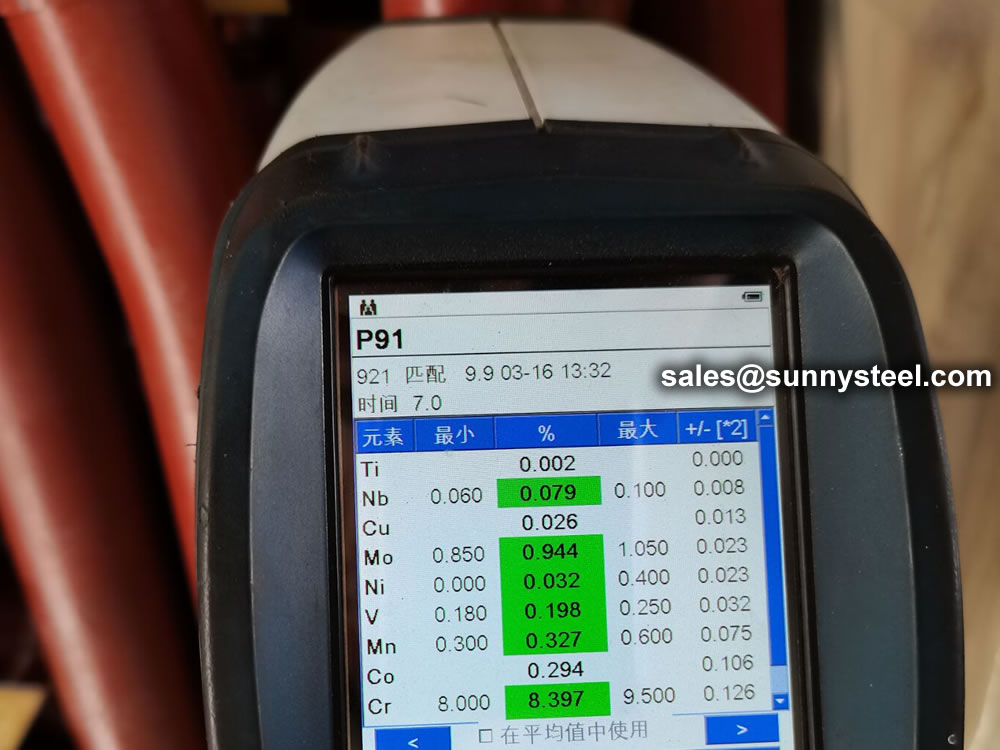

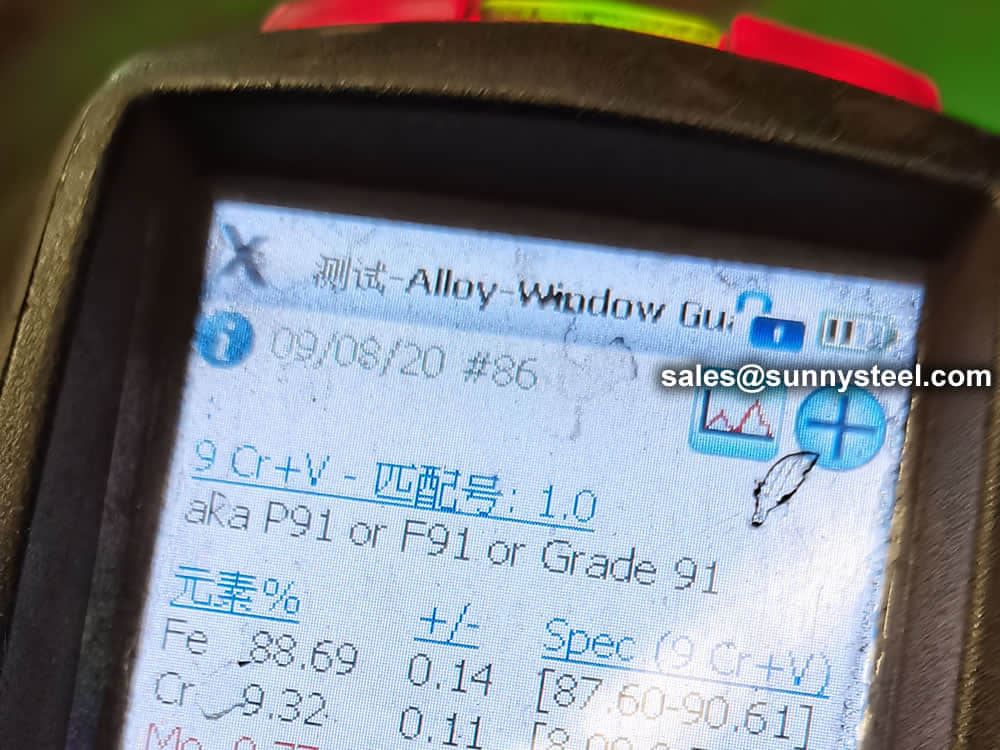

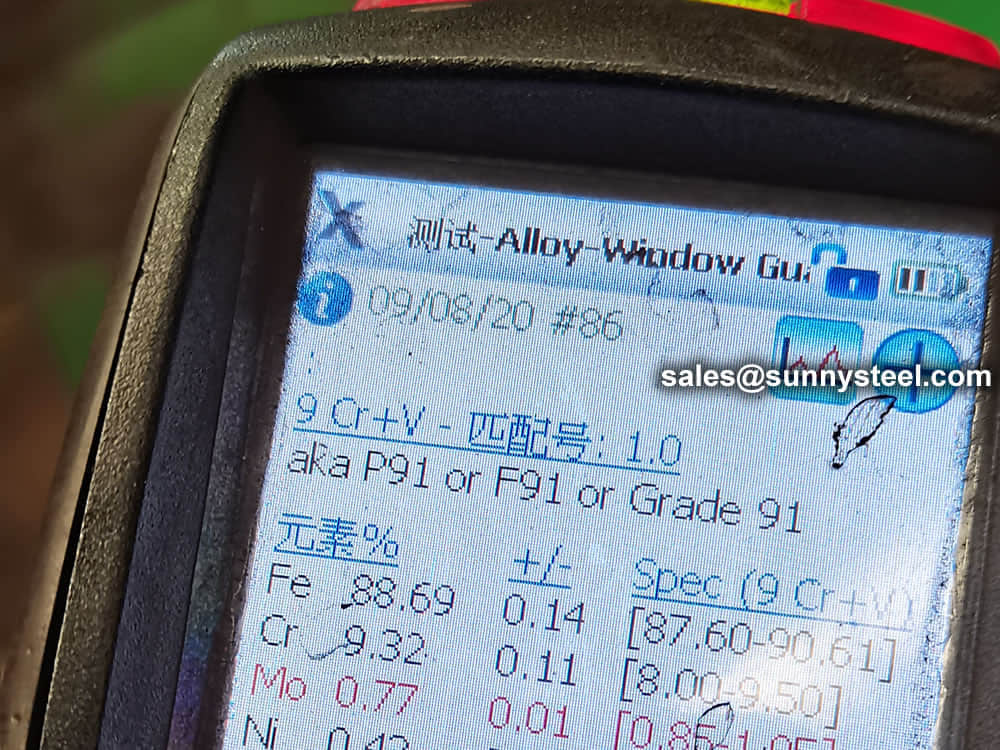

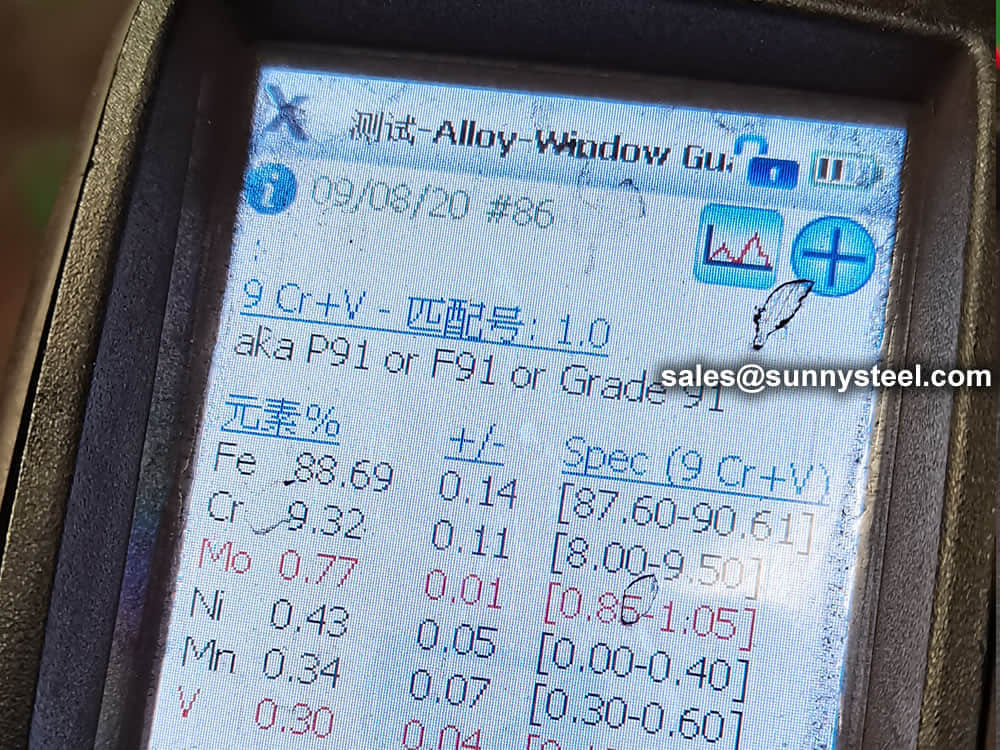

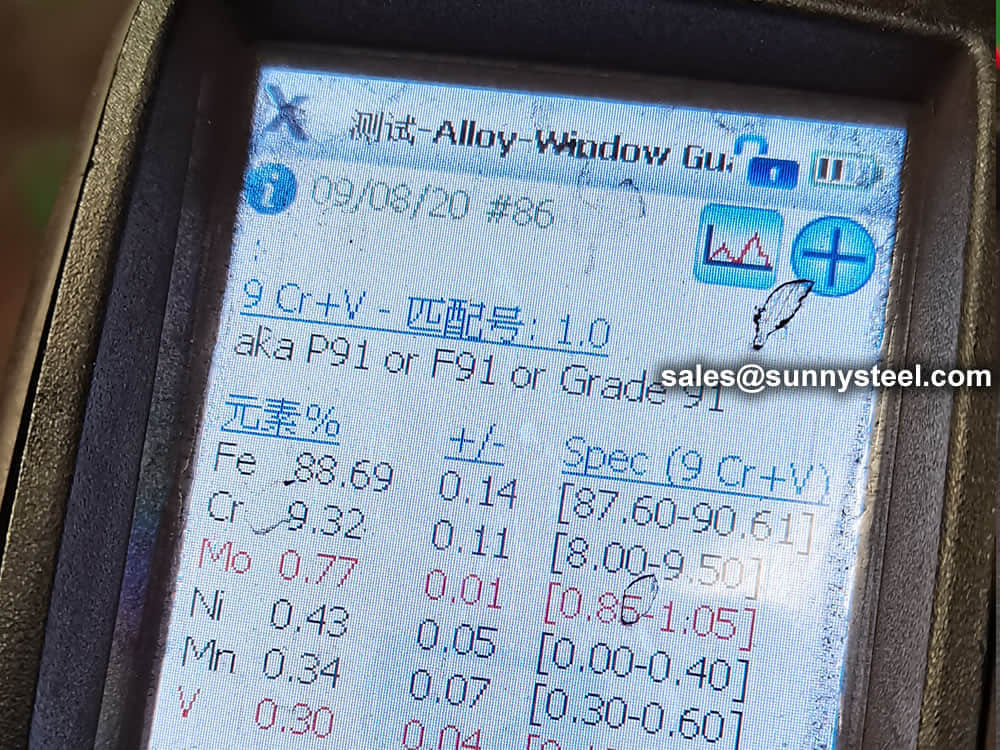

identification of the chemical composition of the metal used to manufacture the fitting. Uses PMI sensors, including X-ray fluorescence or optical emission spectrometry.

Steel pipe delivery status(condition): cold / hard (BK), cold / soft (BKW), after cold stress relief annealing (BKS), annealing (GBK), normalized (NBK).

| Term | Symbol | Explanation |

|---|---|---|

| Cold-finished/hard (cold-finished as-drawn) | BK | No heat treatment after the last cold-forming process. The tubes therefore have only low deformability. |

| Cold-finished/soft (lightly cold-worked) | BKW | After the last heat treatment there is a light finishing pass (cold drawing) With proper subsequent processing, the tube can be cold-formed (e.g. bent, expanded) within certain limits. |

| Annealed | GBK | After the final cold-forming process the tubes are annealed in a controlled atmosphere or under vacuum. |

| Normalized | NBK | The tubes are annealed above the upper transformation point in a controlled atmosphere or under vacuum. |

The general cold strip mills, volume should go through continuous annealing (CAPL unit) to eliminate cold hardening and rolling stress, or batch annealing reach the mechanical properties of the corresponding standard specifies. Cold rolled steel surface quality, appearance, dimensional accuracy better than hot-rolled plate, and right-rolled thin product thickness is about 0.18mm, so the majority of users favor.

Cold rolled steel coil substrate products deep processing of high value-added products. Such as electro-galvanized, hot dip galvanized, electro-galvanized fingerprint resistant, painted steel roll damping composite steel, PVC laminating steel plates, etc., so that the excellent quality of these products has a beautiful, high resistance to corrosion, has been widely used.

Cold rolled steel coil finishing after annealing, cut the head, tail, trimming, flattening, smooth, heavy volume, or longitudinal clipboard. Cold-rolled products are widely used in automobile manufacturing, household electrical appliances, instruments, switches, buildings, office furniture and other industries. Steel plate strapping package weight of 3 to 5 tons. Flat sub-volume typically 3 to 10 tons / volume. Coil diameter 6m.

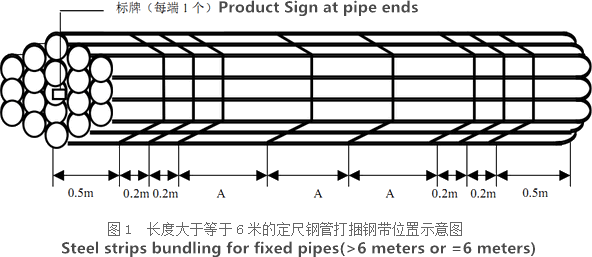

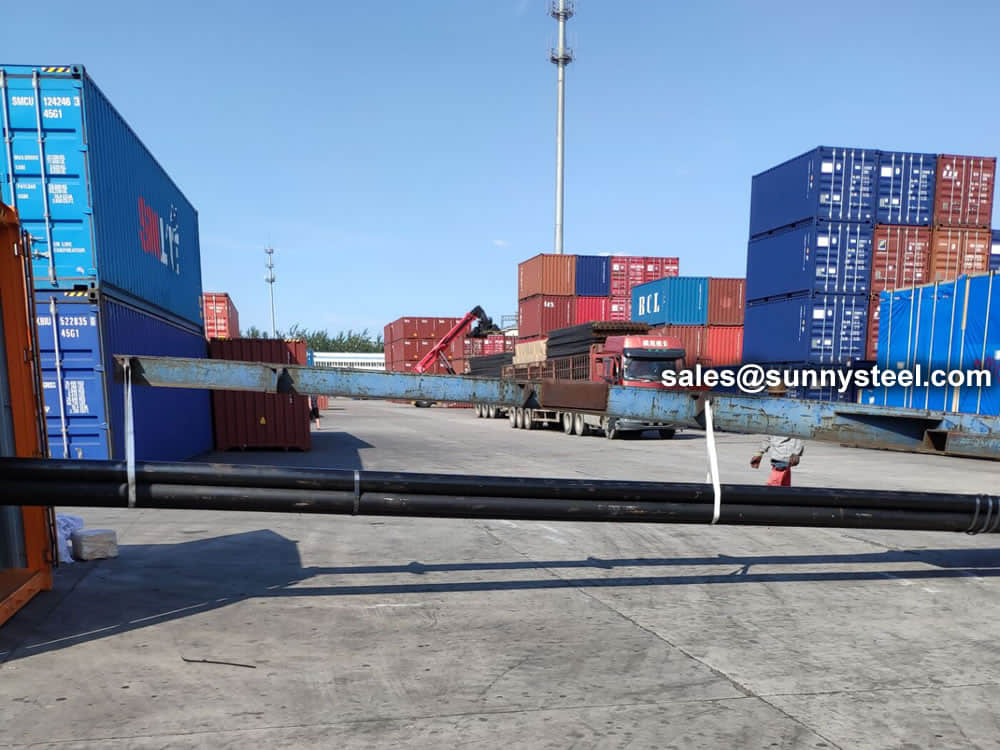

Bare packing/bundle packing/crate packing/wooden protection at the both sides of tubes and suitably protected for sea-worthly delivery or as requested.

There are probably hundreds of different methods for packing a pipe, and most of them have merit, but there are two principles that are vital for any method to work prevent rusting and Sea transportation security.

Our packing can meet any needs of the customers.

Commonly used alloying elements and their effects are listed in the table given below.

| Alloying Elements | Effect on the Properties |

|---|---|

| Chromium | Increases Resistance to corrosion and oxidation. Increases hardenability and wear resistance. Increases high temperature strength. |

| Nickel | Increases hardenability. Improves toughness. Increases impact strength at low temperatures. |

| Molybdenum | Increases hardenability, high temperature hardness, and wear resistance. Enhances the effects of other alloying elements. Eliminate temper brittleness in steels. Increases high temperature strength. |

| Manganese | Increases hardenability. Combines with sulfur to reduce its adverse effects. |

| Vanadium | Increases hardenability, high temperature hardness, and wear resistance. Improves fatigue resistance. |

| Titanium | Strongest carbide former. Added to stainless steel to prevent precipitation of chromium carbide. |

| Silicon | Removes oxygen in steel making. Improves toughness. Increases hardness ability |

| Boron | Increases hardenability. Produces fine grain size. |

| Aluminum | Forms nitride in nitriding steels. Produces fine grain size in casting. Removes oxygen in steel melting. |

| Cobalt | Increases heat and wear resistance. |

| Tungsten | Increases hardness at elevated temperatures. Refines grain size. |