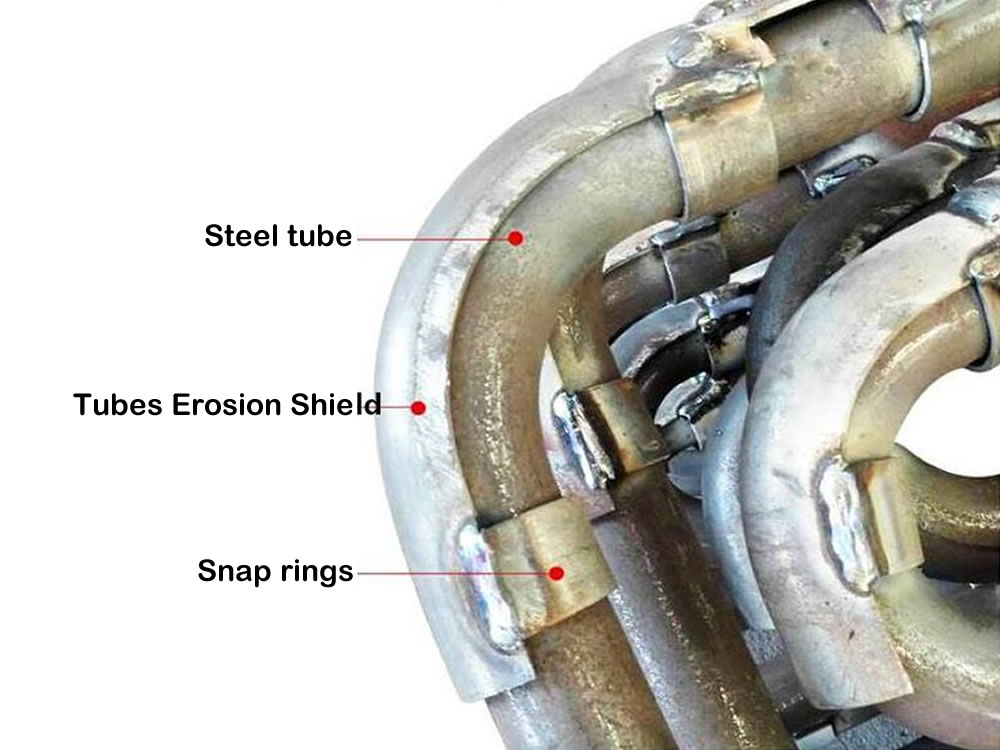

310S stainless snap rings are used in conjunction with boiler tube erosion shields, which is a clip that easily installs boiler tube erosion shields to the tube.

Download PDF310s stainless snap rings are used in conjunction with boiler tube erosion shields, which is a clip that easily installs boiler tube erosion shields to the tube.

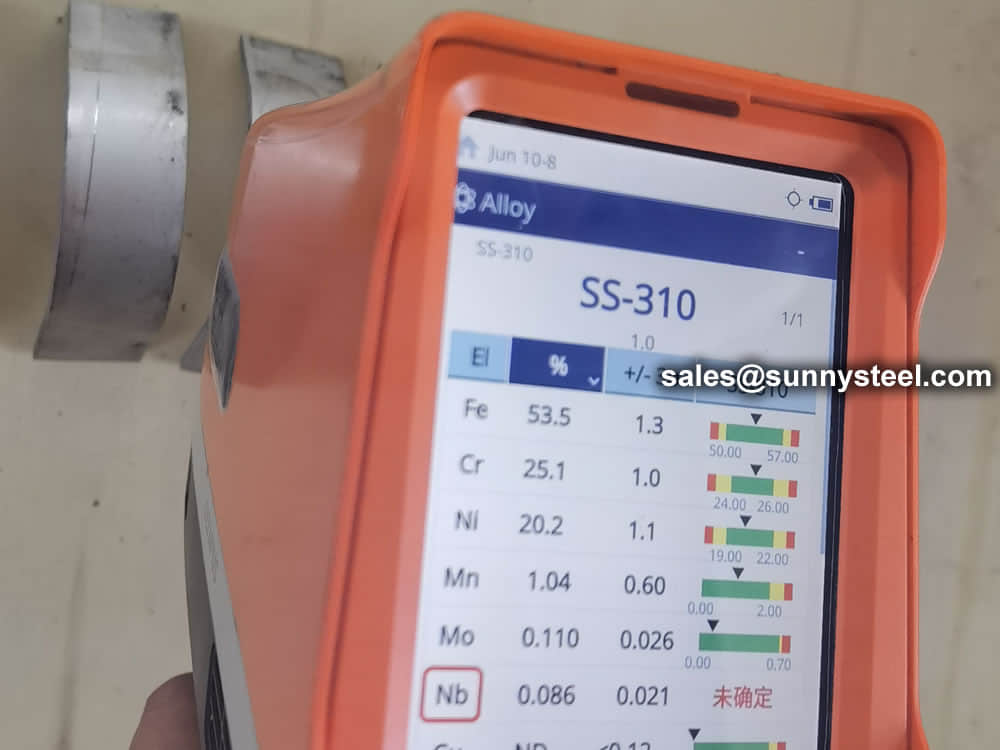

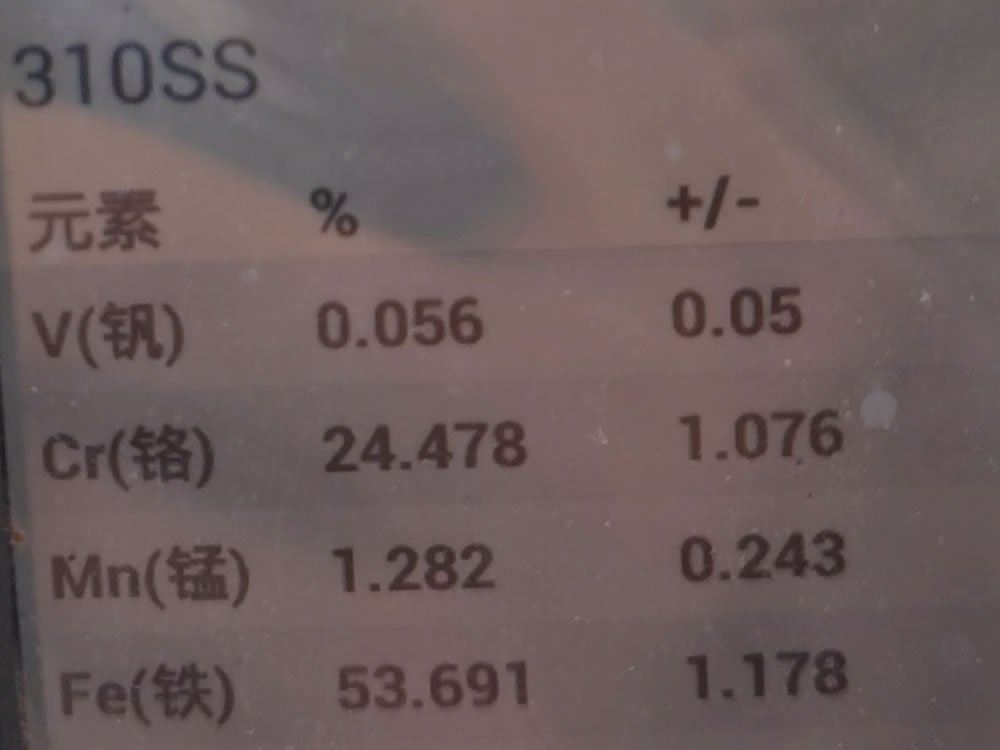

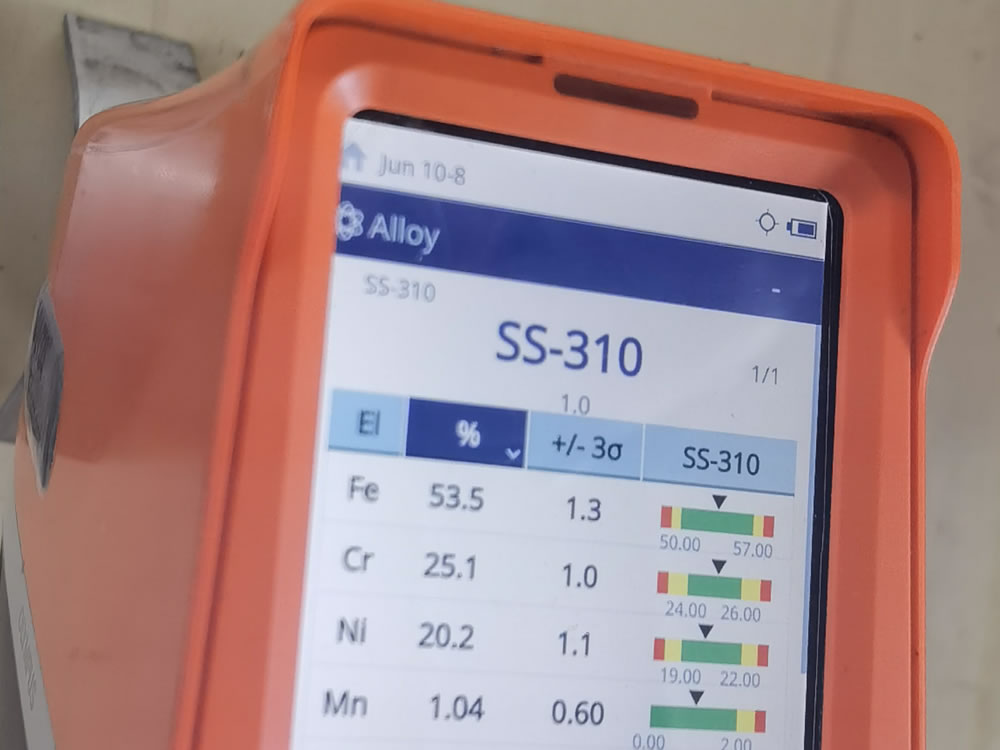

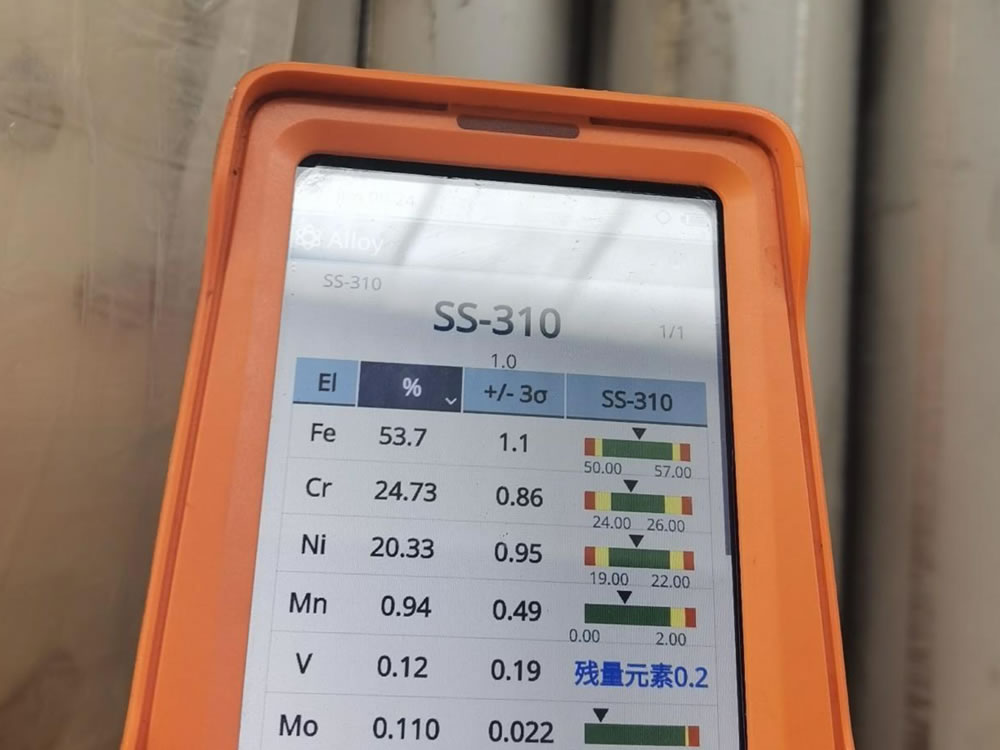

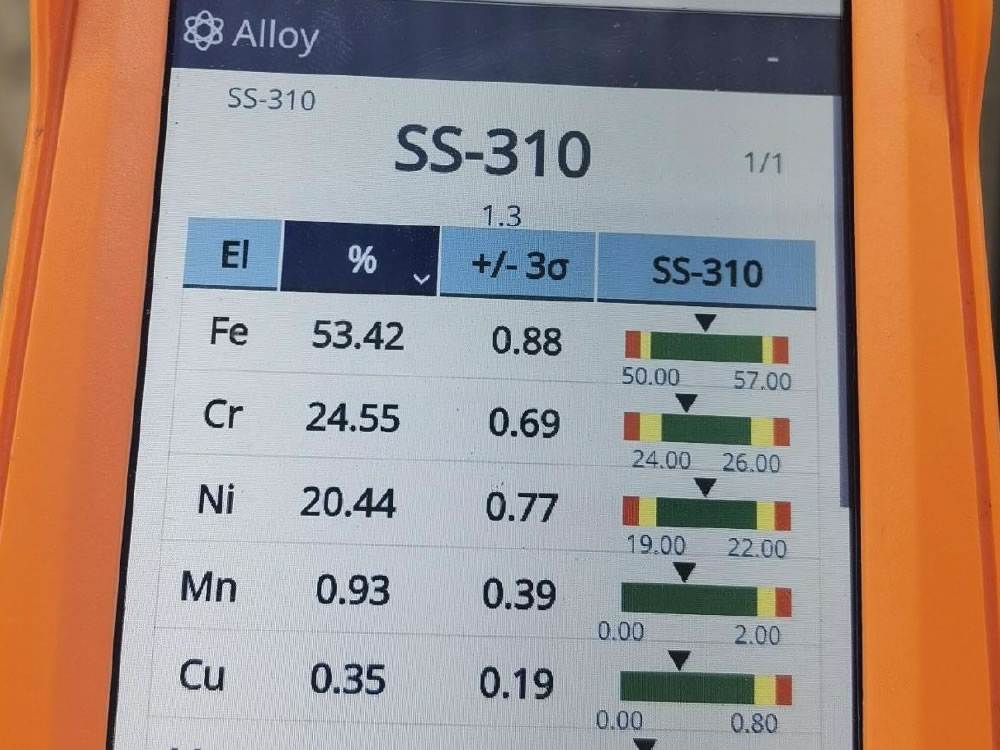

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Fe |

|---|---|---|---|---|---|---|---|---|---|

| SS 310 | 0.015 max | 2.0 max | 0.15 max | 0.020 max | 0.015 max | 24.00 – 26.00 | 0.10 max | 19.00 – 21.00 | 54.7 min |

| SS 310S | 0.08 max | 2.0 max | 1.00 max | 0.045 max | 0.030 max | 24.00 – 26.00 | 0.75 max | 19.00 – 21.00 | 53.095 min |

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

|---|---|---|---|---|---|---|---|

| SS 310 | 1.4841 | S31000 | SUS 310 | 310S24 | 20Ch25N20S2 | - | X15CrNi25-20 |

| SS 310S | 1.4845 | S31008 | SUS 310S | 310S16 | 20Ch23N18 | - | X8CrNi25-21 |

| Item | UNS | ASTM | ASME | AMS |

|---|---|---|---|---|

| 310 | UNS S31000 | ASTM A240 | ASME SA240 | AMS 5521 |

| 310S | UNS S31008 | ASTM A240 | ASME SA240 | AMS 5521 |

| 310H | UNS S31009 | ASTM A240 | ASME SA240 | AMS 5521 |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|

| 7.9 g/cm3 | 1402 °C (2555 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 0.4 |

Alloy 310 can be easily welded and processed by standard shop fabrication practices.

Type 310S Stainless Steel is identical to Type 310 except for a lower carbon content that minimizes carbide precipitation and improves weldability. They are essentially nonmagnetic as annealed and become lightly magnetic when cold worked.

The main role of the anti-wear tile snap ring: the role of fixing the anti-wear tile to avoid problems such as the anti-wear tile falling off during installation.

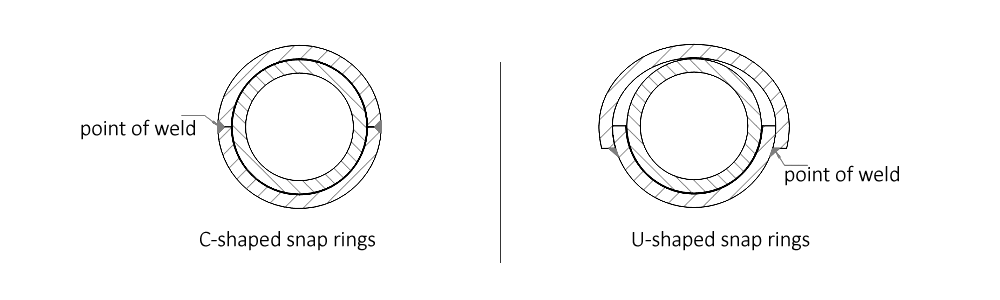

The types of common anti-wear tile rings can be divided into: u-shaped lap type snap ring, butt-type semicircular snap ring.

Typical Applications Grade 310/310S is used in fluidised bed combustors, kilns, radiant tubes, tube hangers for petroleum refining and steam boilers, coal gasifier internal components, lead pots, thermowells, refractory anchor bolts, burners and combustion chambers, retorts, muffles, annealing covers, saggers, food processing equipment, cryogenic structures.

If it is likely to be an issue, discussion with the producer can be valuable as minor variations to the precise composition and process can have benefits.

Grade 310/310S is used in fluidised bed combustors, kilns, radiant tubes, tube hangers for petroleum refining and steam boilers, coal gasifier internal components, lead pots, thermowells, refractory anchor bolts, burners and combustion chambers, retorts, muffles, annealing covers, saggers, food processing equipment, cryogenic structures.

Alloy 310 can be easily welded and processed by standard shop fabrication practices.

Alloy 310 is an austenitic stainless steel that combines excellent high temperature properties with good ductility and weldability. It is typically used for elevated temperature applications as its high chromium and nickel content provide solid corrosion resistance, excellent resistance to oxidation, and superior strength in temperatures up to 2100°F. Due to its high chromium and nickel content, it is superior to 304 or 309 stainless in most environments.

The higher alloyed stainless steels generally have excellent strength at elevated temperatures along with outstanding resistance to creep deformation and environmental attack. Therefore, Alloy 310 is used widely in industries such as heat treatment and chemical processing. Some examples include:

Where heavy sections have to we welded, post-weld annealing may be necessary to restore corrosion resistance.

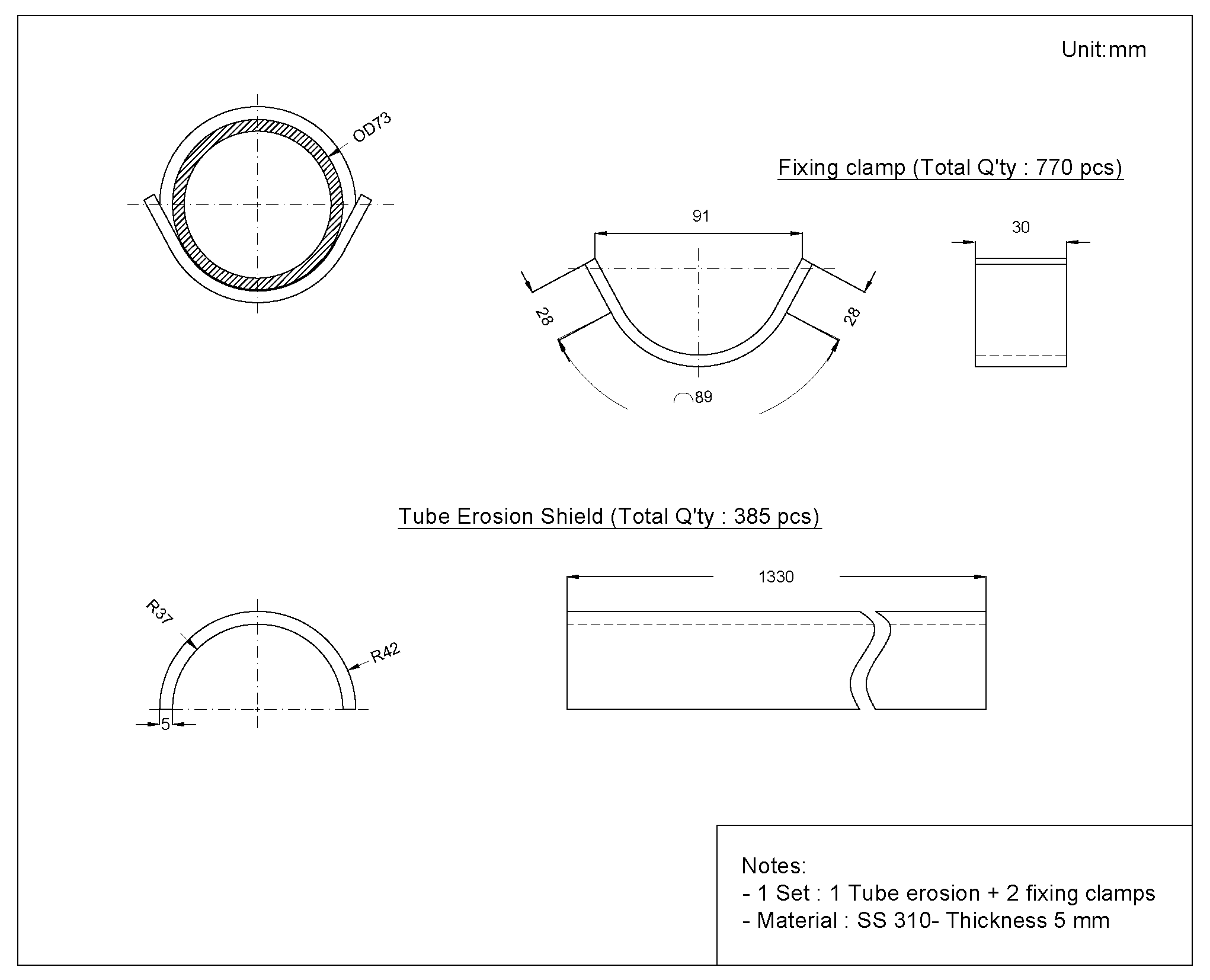

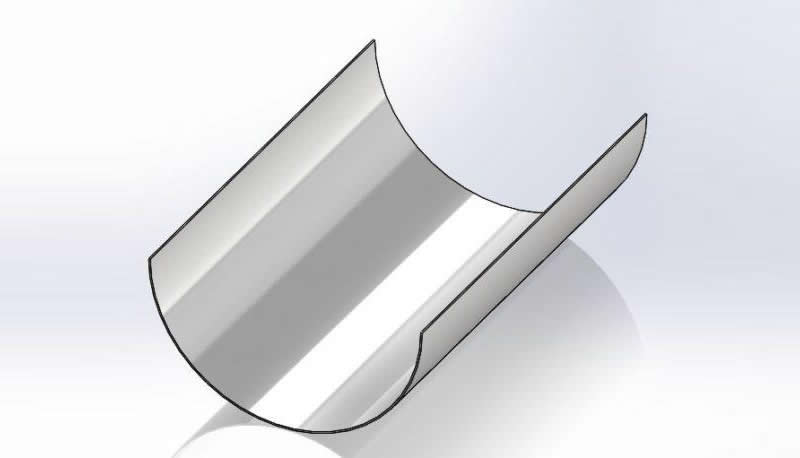

The cross-sectional shape of boiler tube erosion shields is mostly semi-circular (180 degrees), and there are also 120-160 degrees. It is mainly used on finned tubes (water-cooled walls); boiler tubes erosion shields are divided into direct wear-resistant shields, in-curve anti-wear shields, outer-curve anti-wear shields, side-curve anti-wear shields, s-curve anti-wear shields, etc. The length of the straight anti-wear shields ranges from 20mm to 3000mm, and the general length of 1000-2000mm is commonly used. The anti-wear shields with bends generally requires a processing, drawing and the following parameters should be on the drawing: outer diameter of the pipe used, bending of the pipe radius r (to the centre of the pipe), the degree of bending angle, and the length of the straight sections on both sides of the arc segment of the wear-resistant shields.

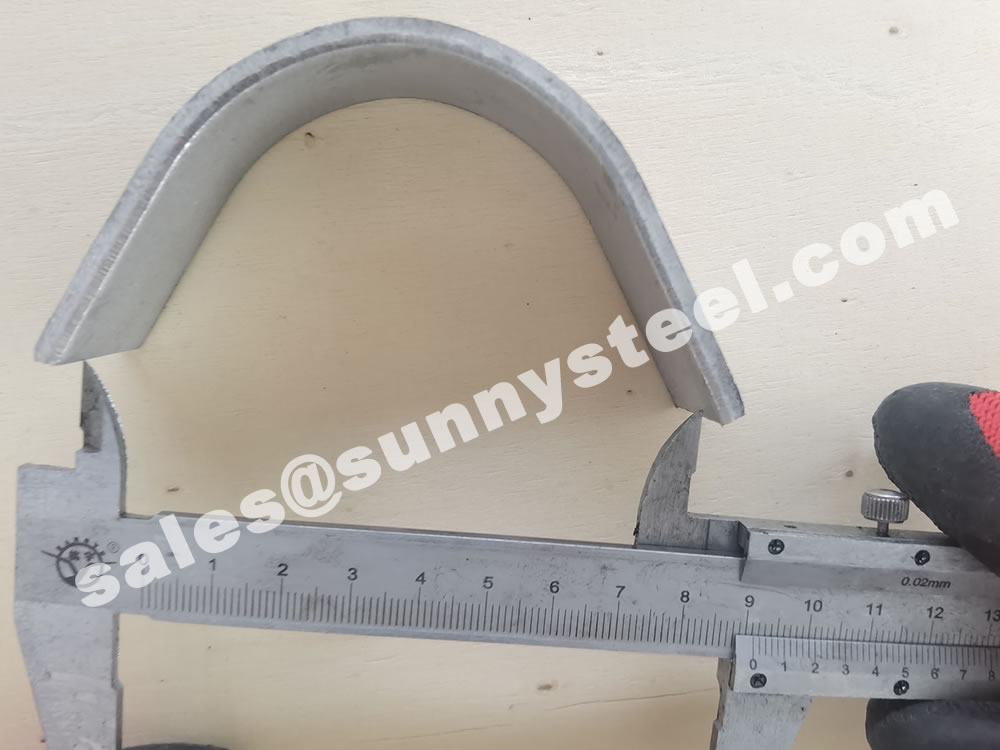

The most basic parameter of boiler tube erosion shields is the outer diameter of the tube used (that is, the inner diameter of boiler tubes erosion shields). The main specifications of the tube are: 32, 38, 42, 44.5, 48, 51, 57, 60, 63.5 , 76, 89mm, etc .; the inner diameter of the boiler tubes erosion shields is usually 1-3mm larger than the outer diameter of the tube used, depending on the actual requirements.

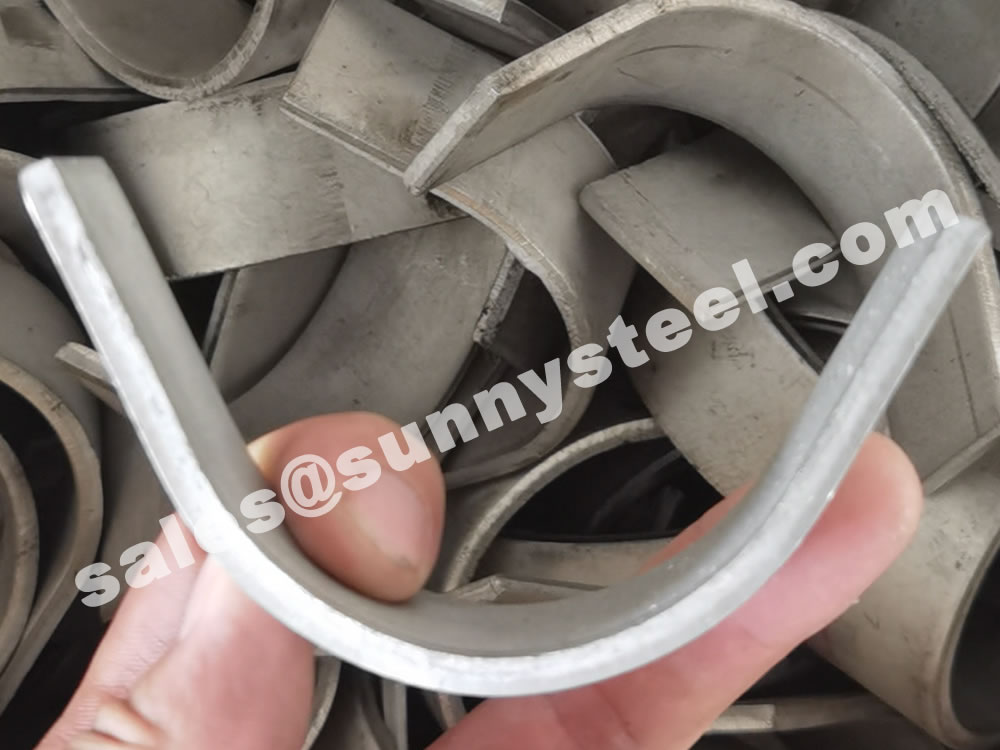

Snap rings are used in conjunction with boiler tubes erosion shields, which is a clip that easily installs boiler tubes erosion shields to the tube.

The snap ring and Boiler Tubes Erosion Shields are overlapped and welded, generally about 190-200 degrees Erosion Shields is a 180-degree semicircle), but also leave a welding position for easy welding and fixing. Generally, each piece of Boiler Tubes Erosion Shields needs to be equipped with 2-4 snap rings with a pitch of 200-500mm.

The anti-wear snap ring is also called clamp, buckle, tube clamp, etc.

The main role of the anti-wear tile snap ring: the role of fixing the anti-wear tile to avoid problems such as the anti-wear tile falling off during installation.

The types of common anti-wear tile rings can be divided into: U-shaped lap type snap ring, butt-type semicircular snap ring.

The inner diameter of the U-shaped snap ring is the outer diameter of the wear-resistant tile plus the thickness of the wear-resistant tile, and the length varies from 20mm to 70mm. It will be 5mm more in semicircle. The extra part during installation will hold the wear-resistant tile and then spot weld. Compared with the butt-type semicircular snap ring, it is stronger after holding the wear-resistant tile and welding.

C-shaped snap ring is the most common snap ring. Mainly based on the size of anti-friction tile, the diameter and thickness are similar to the matching anti-friction tile, and the length varies from 20mm to 70mm. It is mainly connected to the wear-resistant tile by spot welding when installing the wear-resistant tile, so as to fix and prevent the wear-resistant tile from falling off.

Custom snap rings are the recommended method for tube shield attachment.

All products are purchased to proprietary customized specifications as well as normal industry standards with supporting documentation.

Different types of stainless steel are selected according to the specific conditions of different working conditions.

Common materials are: TP321 (Cr18Ni9Ti), TP309S (Cr23Ni13), 1Cr20Ni14Si2, TP310S (Cr25Ni20), 1Cr25Ni20Si2, and some low temperature areas (such as low temperature superheater, low temperature reheater) are made of 1Cr13, 1Cr6Si2Mo and other materials.

The boiler was originally designed to be accurate. Different materials have different temperature resistance and mechanical strength. 1Cr13, 1Cr6Si2Mo generally has a temperature resistance of 600 ℃ or less.

| Material(Grade) | Temperature resistance | Yield strength | Tensile strength | Elongation | HB | HRB | HV |

|---|---|---|---|---|---|---|---|

| 1Cr18Ni9Ti | 925 ℃ | ≥205MPa | ≥520MPa | ≥40% | ≤187 | ≤90 | ≤200 |

| Cr23Ni13 | 1095 ℃ | ≥205MPa | ≥520MPa | ≥40% | ≤187 | ≤90 | ≤200 |

| 1Cr20Ni14Si2 | 1095 ℃ | --- | ≥590MPa | ≥40% | --- | --- | --- |

| Cr25Ni20 | 1150 ℃ | ≥205MPa | ≥520MPa | ≥40% | ≤187 | ≤90 | ≤200 |

| 1Cr25Ni20Si2 | 1150 ℃ | --- | ≥540MPa | ≥35% | --- | --- | --- |

We can also supply boiler tubes erosion shields of other materials.

Generally, boiler tubes erosion shields are also installed to prevent further wear of the tubes and cause serious consequences such as boiler explosion.

The main role is to protect the heating surface of the boiler pipes, reduce pipeline wear, and increase the heating surface of the pipes.

The snap ring is a short section that is installed on the pipe in conjunction with the wear-resistant tile. Generally, it is welded to the wear-resistant tile by lap welding, that is, to cover the wear-resistant tile slightly, so it is larger than the wear-resistant tile. The opening arc is around 190-200 degrees, the welding position needs to be set aside to facilitate welding and fixing. The width of the snap ring must not be less than 20mm.

The installation requirements of anti-friction tiles of different shapes are slightly different. Basically, each anti-friction tile is installed with not less than 2-4 snap rings. The snap ring and the anti-friction tile are welded together to prevent expansion due to heat. The tiles fall off, and the joints are required to be fully welded.

Generally, boiler tubes erosion shields are also installed to prevent further wear of the tubes and cause serious consequences such as boiler explosion.

The main role is to protect the heating surface of the boiler pipes, reduce pipeline wear, and increase the heating surface of the pipes.