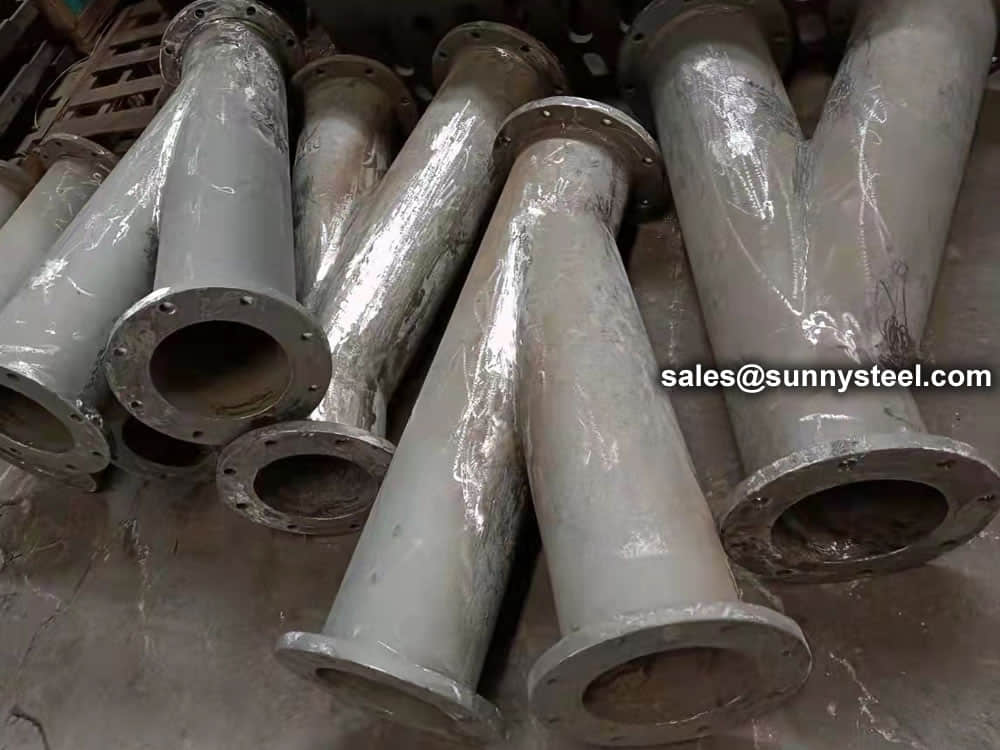

Barred Tee

Barred tees designed for reinforced pipe connections in various industrial applications.

35crmo Steel Pipe Tee is an alloy structural steel with high static strength, impact toughness and high fatigue limit.

35CrMo steel material belongs to alloy structural steel. 35 refers to the carbon content of about 35%, Cr is chromium, and Mo is molybdenum.

35CrMo steel material has high static strength, high impact toughness, high fatigue limit, higher hardenability than 40Cr steel, high temperature resistance, long-term working temperature can reach 500 ℃, poor welding performance.

The main applications of 35CrMo steel material are: it can be processed into important structural parts working under high load, such as the transmission parts of vehicles and engines; the rotor, main shaft, transmission shaft of heavy load and large section parts of turbogenerator.

35CrMo is an alloy structural steel that is commonly used in various applications. It has high static strength, impact toughness, and a high fatigue limit. The hardenability of 35CrMo is higher than that of 40Cr, another commonly used alloy steel. The carbon content of 35CrMo is around 35%, and it contains chromium (Cr) as well.

The hardenability of 35CrMo is higher than that of 40Cr, another commonly used alloy steel. The carbon content of 35CrMo is around 35%, and it contains chromium (Cr) as well.

Delivery condition: annealing / tempering.

Hardness: ≦229 HBW

Characteristic:35CrMo has high static strength, impact toughness and high fatigue limit, harden ability is higher than 40Cr , higher creep strength and lasting strength under high temperature , long-term working temperature up to 500 ℃.

Application: 35CrMo alloy pipe is used to manufacture important parts of various machines that bear the impact, twist and high

The pipe tee is currently the most frequently used pipe fitting or connector in the industry.

Its functionality is analogous to that of elbows, enabling the creation of branch connections for linear pipelines. As indicated by the name TEE, the shape is T-shaped with two outlets at 90° to the connection to the main line. The pipe piece is of a short length and features an integrated outlet. This is used to connect and take taps with a pipe at a right angle to the linear line. These can be fabricated with various materials, including stainless steel, carbon steel, cast iron, nickel, aluminum, copper, brass, bronze, plastic, rubber, and polypropylene. They are available in a variety of sizes and finishes, such as galvanized, nickel-plated, black cast steel, white coating, gold finish electroplated, and more. These options can be selected based on the end user's requirements. Pipe tees are a common solution in pipeline networks for transporting two-phase fluid mixtures. They can also be used as an alternative to o-rings.

The standard construction of T-shaped elbows (TEs) comprises three openings on the sides of the pipe tees, with two openings being narrower than the other. In some instances, the third opening may be at a 90-degree angle, subject to user requirements. In the case of straight pipe tees with identical opening sizes on all sides, these are referred to as equal tees. Alternatively, they may be classified as reducing tees, which feature one opening of a different size and two openings of the same size. Sanitary pipe tees are a type of pipe tee with a curved branch designed for a clean-out plug, and are used in waste lines. One advantage of this is that it prevents blockages in waste lines. Additionally, a cross pipe tee is available, featuring four equal-sized female openings. It should be noted that this type of pipe tee is not typically used in high-pressure systems and is not a common feature. The opening is threaded and used in conjunction with a threaded plug for a clean-out opening on a drain pipe. The ASME standards for tee design are ASME/ANSI B16.9 or ASME/ANSI B16.11, and the pipe tees are constructed by forging or casting.

A tee fitting is a static component of a piping system, designed to connect two or three different pipelines at a single point. These pipelines, which need to be joined via the tee fitting, may have the same diameter, schedule/pressure class, or may vary according to specific requirements. The primary function of a tee fitting is to redirect fluid flow in different directions.

There are several types of tee fittings:

Further classifications of tee fittings are based on end connection types, which include:

Equal tees are used when all openings of the tee fitting are equal in diameter. The branch connection may be angled, such as 90° or 45°, or any other angle as needed. Equal tees are selected when all branch pipes have the same diameter, ensuring consistent design and dimensions for easy fabrication.

Unequal tees are utilized when the branch pipes have different diameters. The branch connection can be set at angles like 90°, 45°, or any other angle. This type of tee fitting is also used when one or both outlets of the tee are smaller than the main pipeline diameter. However, the design and dimensions used to fabricate unequal tees remain similar to those of equal tees.

The branch of a tee refers to the connection that diverts flow from the main pipeline at a specific angle, such as 90° or 45°. This branch can either match the main pipeline’s diameter (equal branch) or have a smaller diameter (reducing branch) based on the system requirements.

Sanitary tees are used in T-shaped sanitary pipe fittings, which connect a branch line to a vertical drain line or vent line. Sanitary tees can be manufactured with an existing pipeline diameter or with different diameters to connect to other pipes or valves with different fitting sizes. Sanitary tees are available in a wide range of capacities, classes, shapes and sizes, but can be broadly classified into two main types, which are the most frequently used in industrial and plumbing applications.

In the behavior, we make beveling after shot blasting, bevel ends are fully machined by advanced equipment Double Beveling Machine ensure the height, length, thickness, O.D. and I.D. are all qualified.

Welding Bevel acc. to

The ends of all buttweld fittings are bevelled, exceeding wall thickness 4 mm for austenitic stainless steel, or 5 mm for ferritic stainless steel. The shape of the bevel depending upon the actual wall thickness. This bevelled ends are needed to be able to make a “Butt weld”.

ASME B16.25 covers the preparation of buttwelding ends of piping components to be joined into a piping system by welding. It includes requirements for welding bevels, for external and internal shaping of heavy-wall components, and for preparation of internal ends (including dimensions and dimensional tolerances).

Our in-hourse R&D team developed bevel ends equipment are good using in thickness 2mm to 20mm pipe fittings, guarantee high efficiency and high quality.

| Nominal wall Thickness : t | End Preparation |

|---|---|

| t<5mm (for austenitic alloy steel | Cut square or slightly chamfer |

| t<4mm) | at manufacturer ' s option |

| 5<22mm (4<22mm)< td="" style="box-sizing: border-box;"><22mm)<><22mm |

Plain Bevel as in sketch ( a ) above |

| t>22mm | Compound Bevel as in sketch ( b ) above |

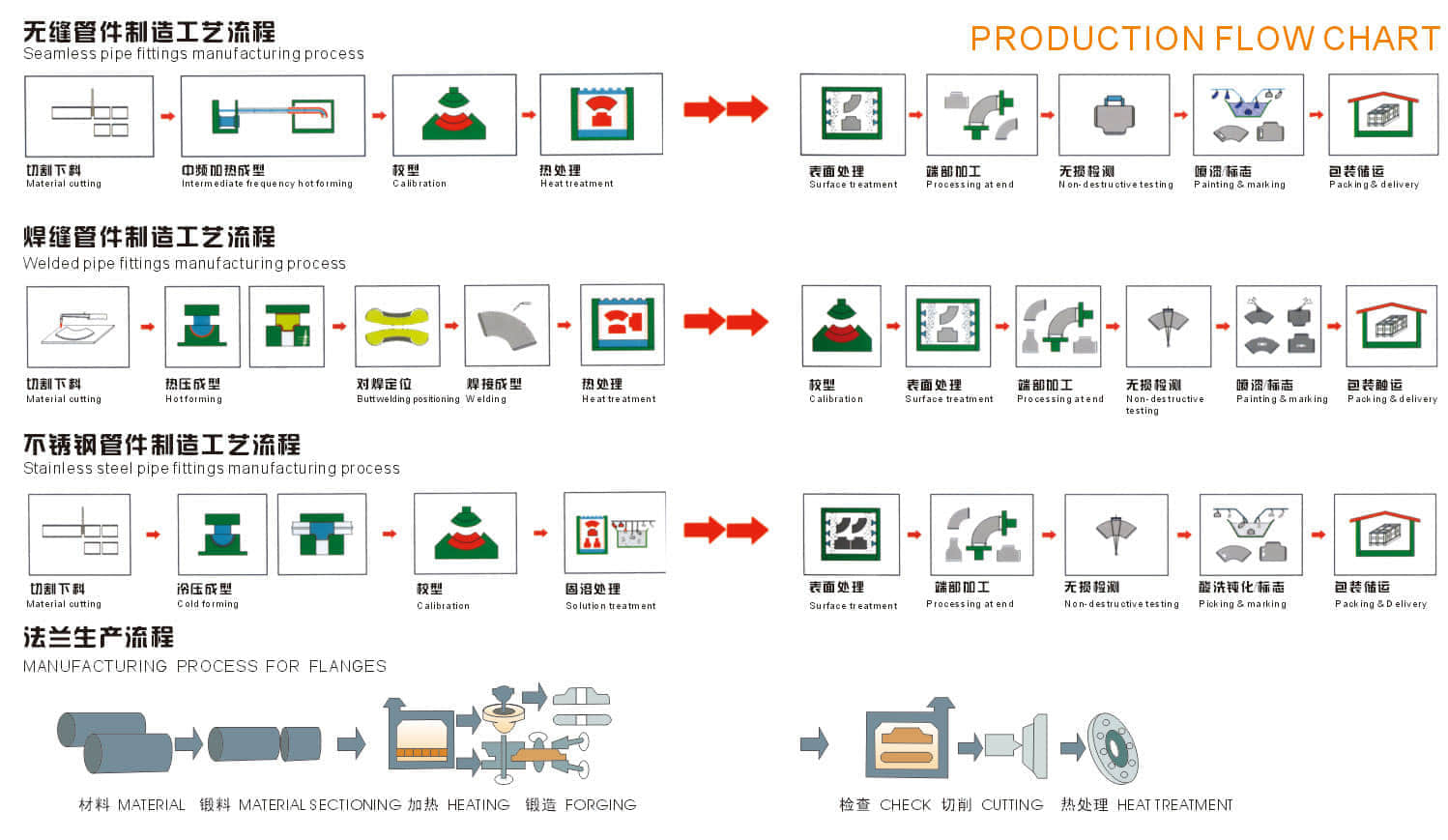

For the manufacturing process of all pipe fittings, forming is an indispensable process. Because the forming process of different products is different, it needs a long time.

Heating

In order to meet the requirements of material deformation in the forming process, it is necessary to heat the blank when the tube is manufactured by hot forming method. The temperature usually depends on the material and heating process.

During the forming of hot pushing elbow or hot bending elbow, the medium frequency or high frequency induction heating method is usually used, and the flame heating method is also used. This kind of heating mode is continuous heating which is synchronous with the forming process of elbow or elbow. The tube blank is heated in motion and the forming process is completed.

When hot pressing elbow, hot pressing tee or forging are formed, the heating method of reverberatory furnace, flame heating, induction heating or electric furnace heating are usually adopted. This kind of heating is to first heat the tube blank to the required temperature, and then put it into the die for pressing or forging.

Welding

There are two kinds of pipe fittings with welding seam. One is the pipe fittings made of welded pipe. For the pipe fitting manufacturer, the forming process of welded pipe is basically the same as that of seamless pipe, and the forming process of pipe fitting does not include welding process; the other is that the pipe fitting manufacturer completes the welding process required for pipe fitting forming, such as the elbow formed by assembling and welding after single piece pressing The tee pipe is welded into tube blank after being rolled by steel plate drum, etc.

The commonly used welding methods of pipe fittings are manual arc welding, gas shielded welding and automatic welding.

Our factory guides the welding work according to the preparation of the welding procedure specification, and carries out the welding procedure qualification according to the corresponding specification requirements, so as to verify the correctness of the welding procedure specification and evaluate the welding ability of the welder.

One of the most common manufacturing methods for caps, where plate is cut out in a circle and formed by deep drawing.

Deep drawing is the manufacturing process of forming sheet metal stock, called blanks, into geometrical or irregular shapes that are more than half their diameters in depth. Deep drawing involves stretching the metal blank around a plug and then moving it into a moulding cutter called a die.

A drawing press can be used for forming sheet metal into different shapes and the finished shape depends on the final position that the blanks are pushed down in. The metal used in deep drawing must be malleable as well as resistant to stress and tension damage.

Pipe Tees are widely used in various commercial and industrial applications. Industrial applications include.

We are manufacturer of Reducing tee and supply high quality Reducing tee in both large and small quantities worldwide & offer you the best prices in the market.

Visual Inspection is conducted on fittings to check any surface imperfections. Both fittings body and weld are checked for any visible surface imperfections such as dents, die marks, porosity, undercuts, etc. Acceptance as per applicable standard.

For packing of carbon steel flanges with painting,we would use the bubble wrap to protect the painting.For flanges without painting or oiled with long-term shipment,we would suggest client to use the anti-tarnish paper and plastic bag to prevent the rust.