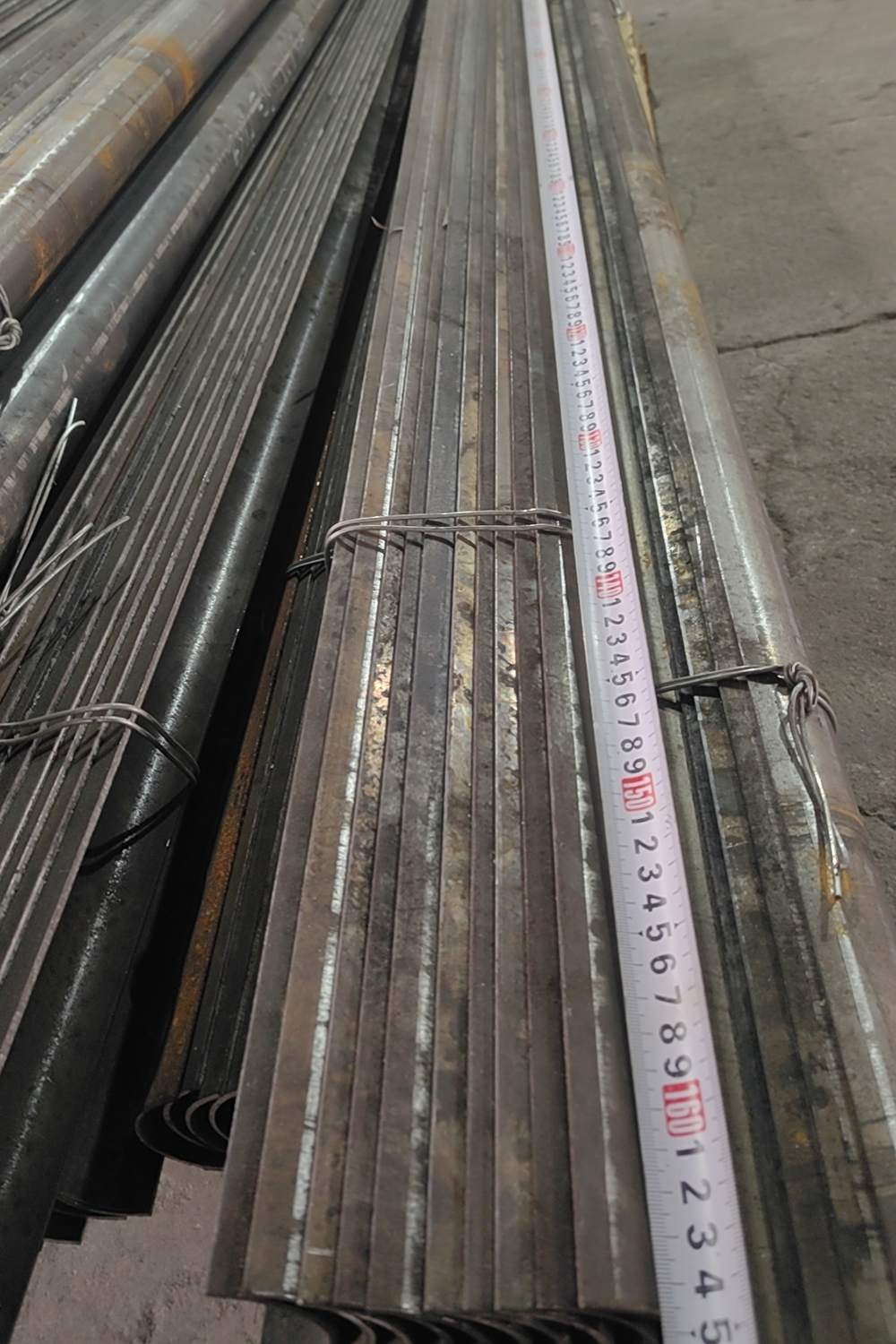

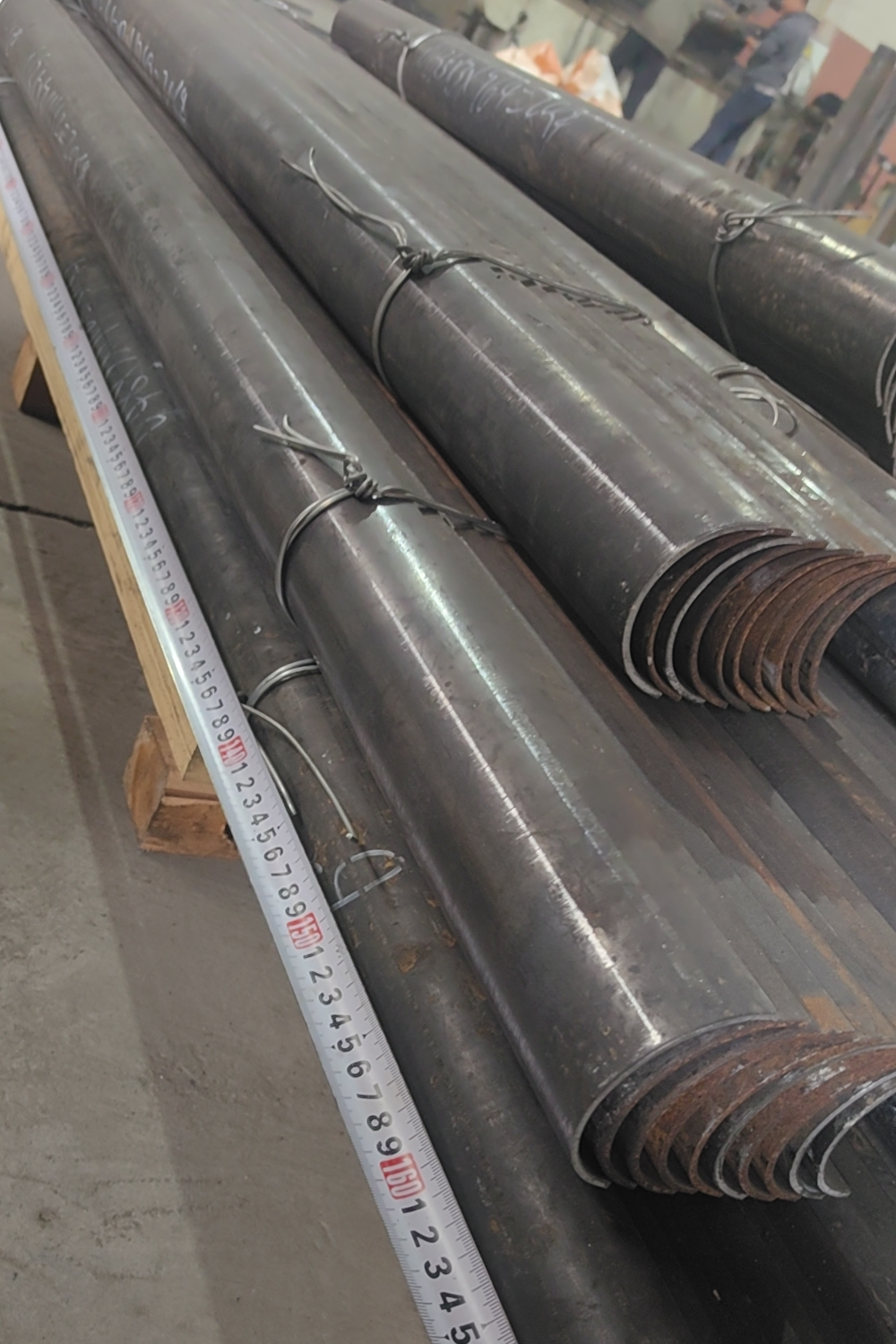

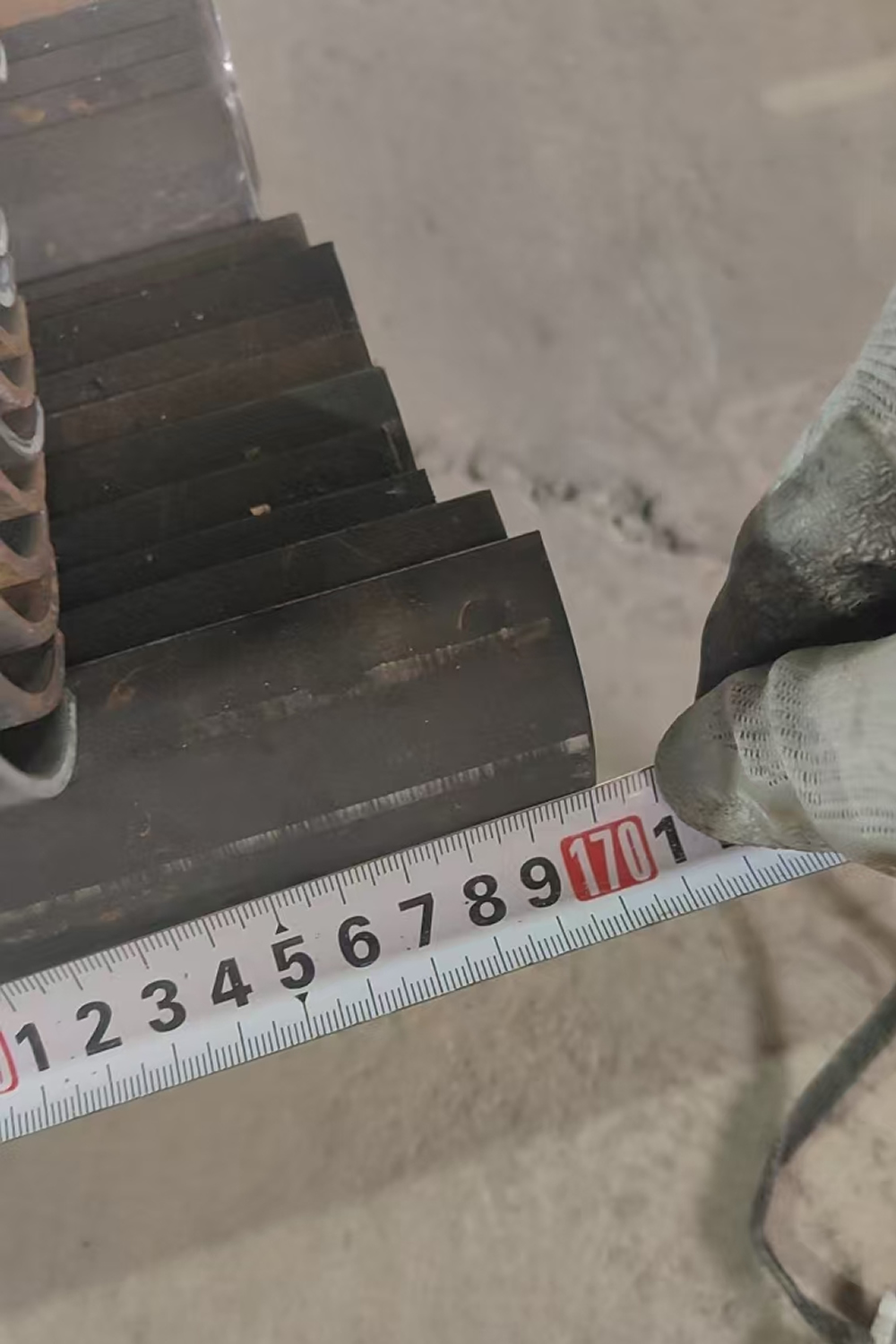

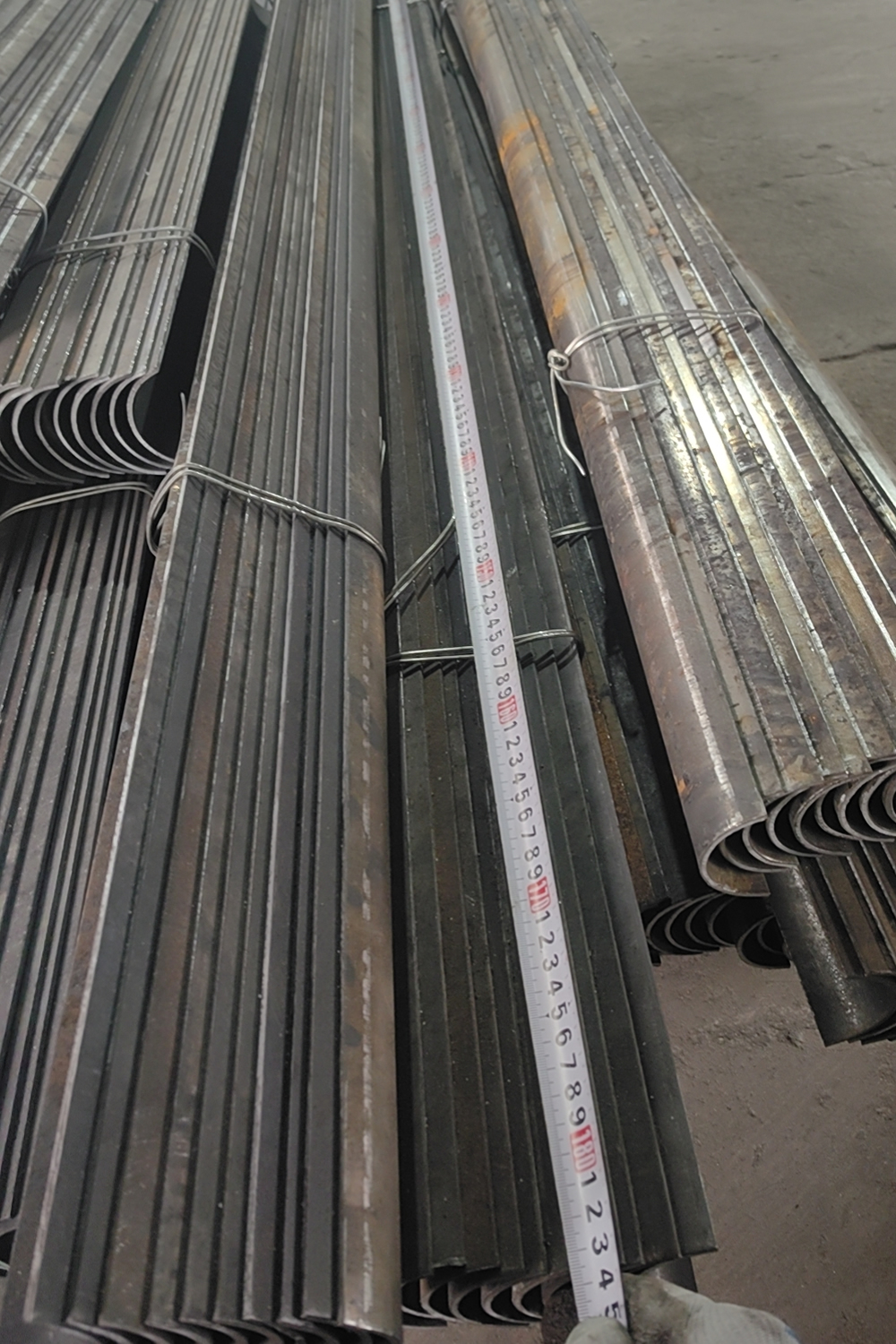

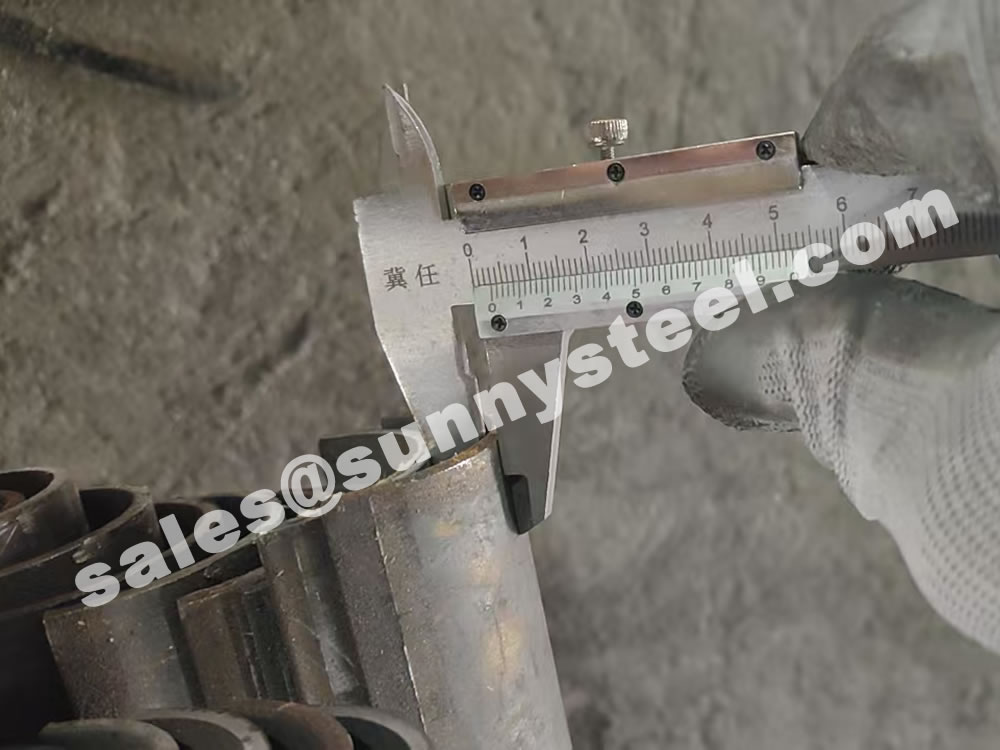

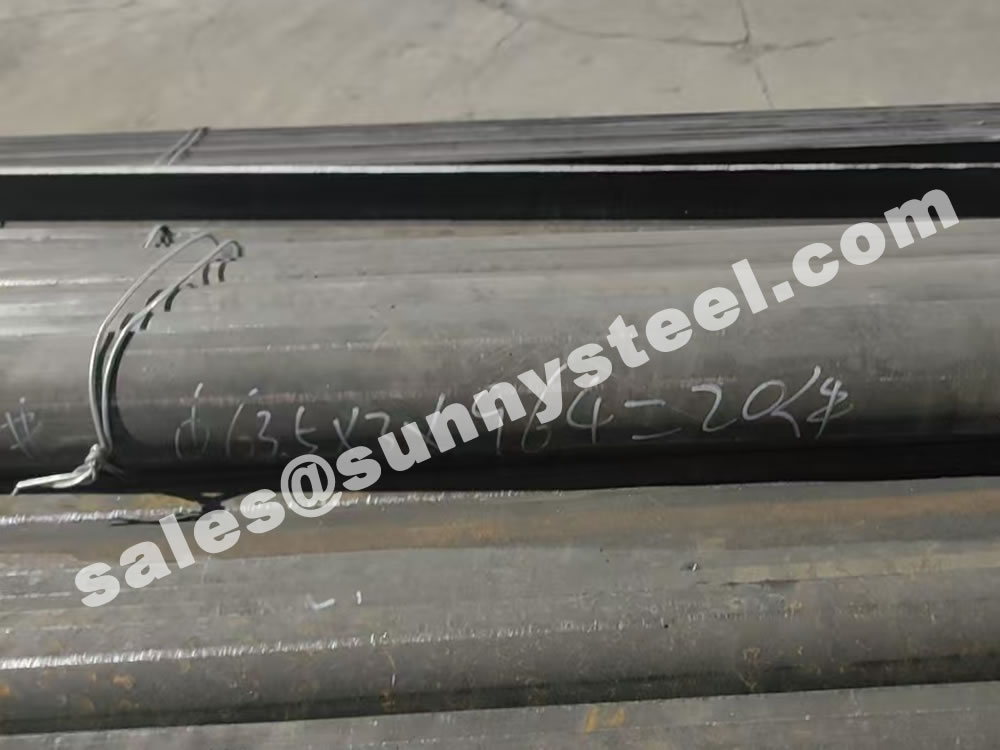

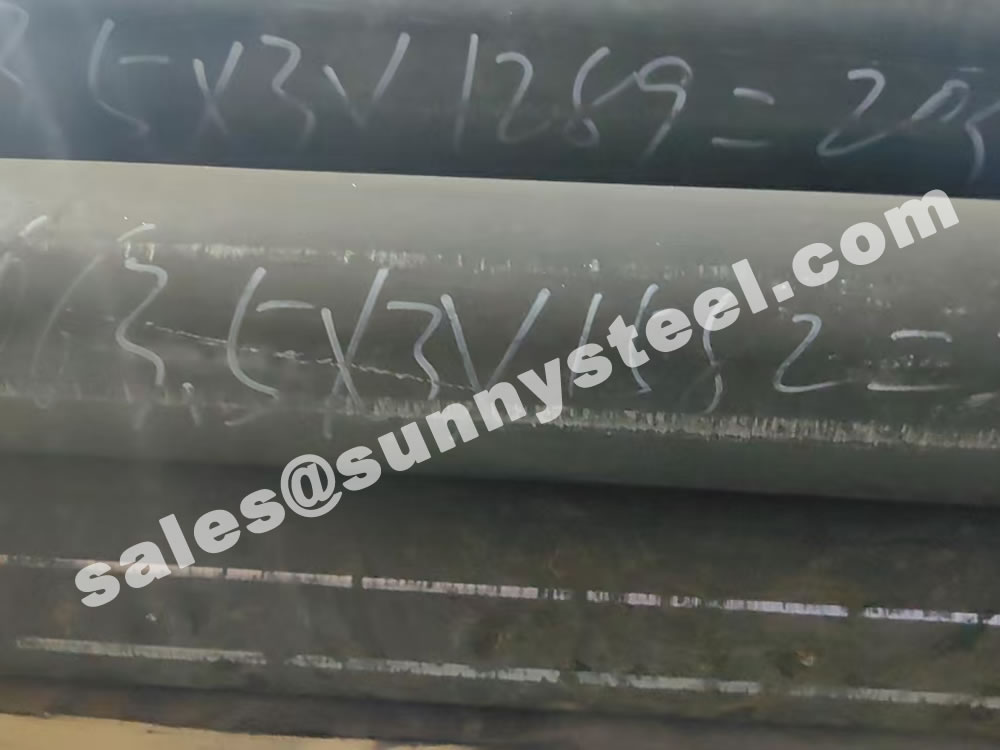

1Cr6Si2Mo straight erosion shield protector offers exceptional wear and erosion resistance in high-temperature industrial applications.

Made from high-performance alloy steel, it is widely used in industrial applications where reliability and durability are paramount.

The 1Cr6Si2Mo erosion shield clamp is specifically engineered to provide exceptional resistance to erosion and wear under high-temperature conditions. Made from high-performance alloy steel, it is widely used in industrial applications where reliability and durability are paramount.

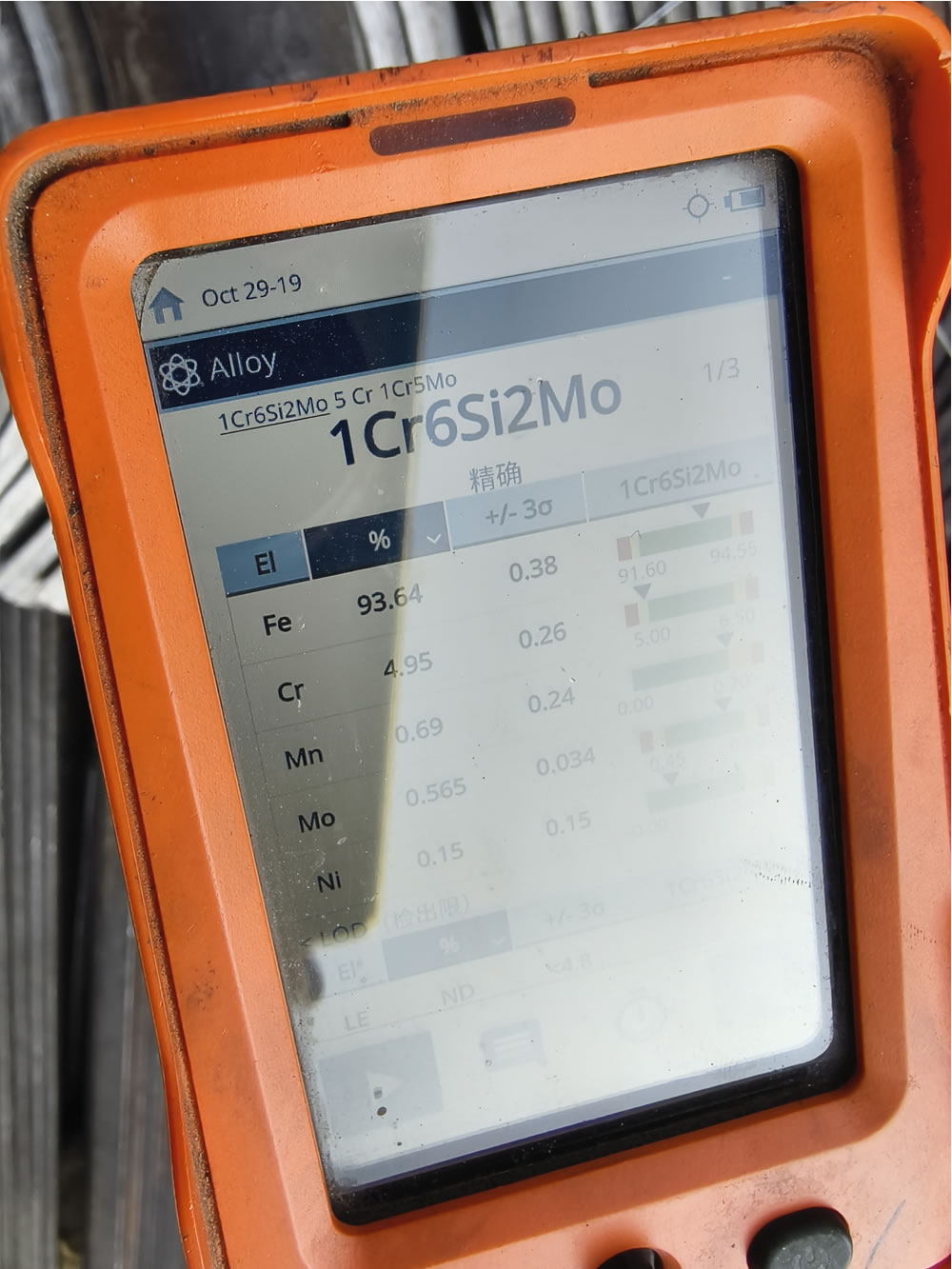

| Element | Content (%) |

|---|---|

| Carbon (C) | ≤ 0.15 |

| Silicon (Si) | 1.5 - 2.0 |

| Manganese (Mn) | ≤ 0.7 |

| Phosphorus (P) | ≤ 0.035 |

| Sulfur (S) | ≤ 0.030 |

| Chromium (Cr) | 5.2 - 6.0 |

| Molybdenum (Mo) | 0.45 - 0.6 |

1Cr6Si2Mo is a martensitic heat-resistant steel with good oxidation resistance at 800°C. Compared with 1Cr5Mo steel, since it contains 1.5% silicon (Si), the temper brittleness tendency of 1Cr6Si2Mo increases, and brittle fracture may occur when working at high temperatures for a long time. This material shows good corrosion resistance in sulfur-containing oxidizing atmospheres and hot petroleum media.

After normalizing and tempering heat treatment, 1Cr6Si2Mo has high creep strength and durability. In addition, 1Cr6Si2Mo has an air quenching phenomenon. If it cools too quickly after hot processing, cracks may occur, so slow cooling is required.

Its weldability is poor. Electric welding is recommended instead of gas welding. It needs to be preheated to 300°C - 400°C before welding and tempered at 750°C after welding.

| Property | Value |

|---|---|

| Tensile Strength | ≥ 547 MPa |

| Yield Strength | ≥ 401 MPa |

| Elongation | ≥ 31.5% |

The 1Cr6Si2Mo erosion shield clamp is widely used in various industries, including: