Tube shield ET wear shield 316L are made of 316L stainless steel and can be customized to fit perfectly straight sections, curved sections and even finned and specialty tubes.

Download PDFStainless steel 316 (SS316) is an austenitic chromium-nickel stainless steel containing deliberate amount of molybdenum which increases general corrosion resistance and especially improves its pitting resistance to chloride ion solutions.

AISI 316L stainless steel is a modified ultra-low carbon Cr-Ni-Mo series austenitic stainless steel based on AISI 316. It is recommended for parts that cannot be annealed after welding in certain corrosive environments. The addition of molybdenum can provide pitting resistance in phosphoric acid and acetic acid and dilute chloride solutions and corrosion resistance in sulfurous acid. SS316L is resistant to carbide precipitation in the temperature range of 425-870 °C (800-1600 °F), so normal welding can be performed without reducing corrosion resistance. However, when it is heated and kept in the sensitization temperature range for a long time during use, a large amount of carbides will precipitate, so it is usually recommended to use it below 425 °C (800 °F).

All these years have enhanced our capabilities and enabled us to produce all kinds of standard tube shield as well as custom snap rings as per customer’s specifications. We have numerous combinations of sizes readily available in large number of stocks and can fabricate custom sizes according to customer’s requirement.

Type 316L stainless steel density is 0.289 lb/in3 (8.0 g/cm3); melting point is 1375-1400 °C (2500-2550 °F); 0.2% yield strength is minimum 25 ksi (170 MPa) in annealed and hot finished condition, minimum 45 ksi (310 MPa) in annealed and cold finished condition; Minimum tensile strength is 70 ksi (485 MPa) in annealed and hot finished condition, ≥ 90 ksi (620 MPa) in annealed and cold finished condition; Maximum Brinell hardness is 217 HB, Maximum Rockwell hardness is 90 HRBW; Thermal conductivity is 12.1 W/m·K at 20 °C (68 °F), 16.3 W/m·K at 100 °C (212 °F).

The chemical composition of ASTM A240 Grade 316/316L Stainless Steel is outlined in the following table

| Grade | Scope | C | Mn | Si | P | S | Cr | Mo | Ni | N |

|---|---|---|---|---|---|---|---|---|---|---|

| 316 | Min | - | - | - | 0 | - | 16 | 2 | 10 | - |

| Max | 0.08 | 2 | 0.75 | 0.045 | 0.03 | 18 | 3 | 14 | 0.1 | |

| 316L | Min | - | - | - | - | - | 16 | 2 | 10 | - |

| Max | 0.03 | 2 | 0.75 | 0.045 | 0.03 | 18 | 3 | 14 | 0.1 | |

| 316H | Min | 0.04 | 0.04 | 0 | - | - | 16 | 2 | 10 | - |

| max | 0.1 | 0.1 | 0.75 | 0.045 | 0.03 | 18 | 3 | 14 | - |

| Grade | Tensile Str | Yield Str 0.2% Proof |

Elong | Hardness | |

|---|---|---|---|---|---|

| (MPa) min | (MPa) min | (% in 50mm) min | Rockwell B (HR B) max | Brinell (HB) max | |

| 316 | 515 | 205 | 40 | 95 | 217 |

| 316L | 485 | 170 | 40 | 95 | 217 |

| 316H | 515 | 205 | 40 | 95 | 217 |

| Grade | Why it might be chosen instead of 316? |

|---|---|

| 316Ti | Better resistance to temperatures of around 600-900 °C is needed. |

| 316N | Higher strength than standard 316. |

| 317L | Higher resistance to chlorides than 316L, but with similar resistance to stress corrosion cracking. |

| 904L | Much higher resistance to chlorides at elevated temperatures, with good formability |

| 2205 | Much higher resistance to chlorides at elevated temperatures, and higher strength than 316 |

| 316 | 316L |

|---|---|

| ASTM A240 | ASTM A240 |

| ASTM A666 | ASTM A666 |

| ASME SA240 | ASME SA240 |

| AMS 5524 | AMS 5507 |

The main difference between 316 and 316l stainless steel is in their carbon content. The 316L stainless steel compared to the 316 variant has a lower carbon content. Therefore, in terms of use for example, use related to corrosion, 316L is more capable than 316 stainless steel.

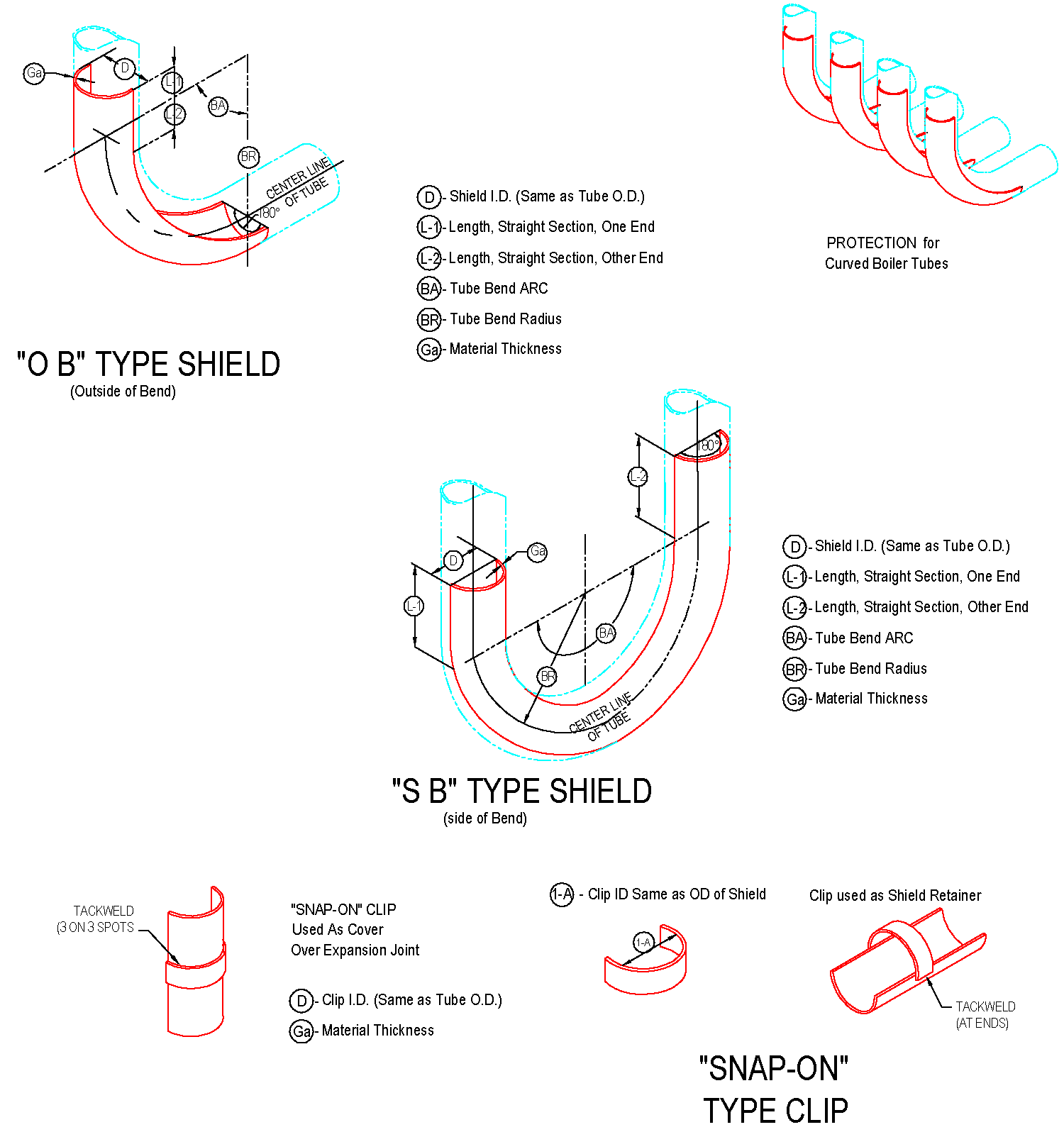

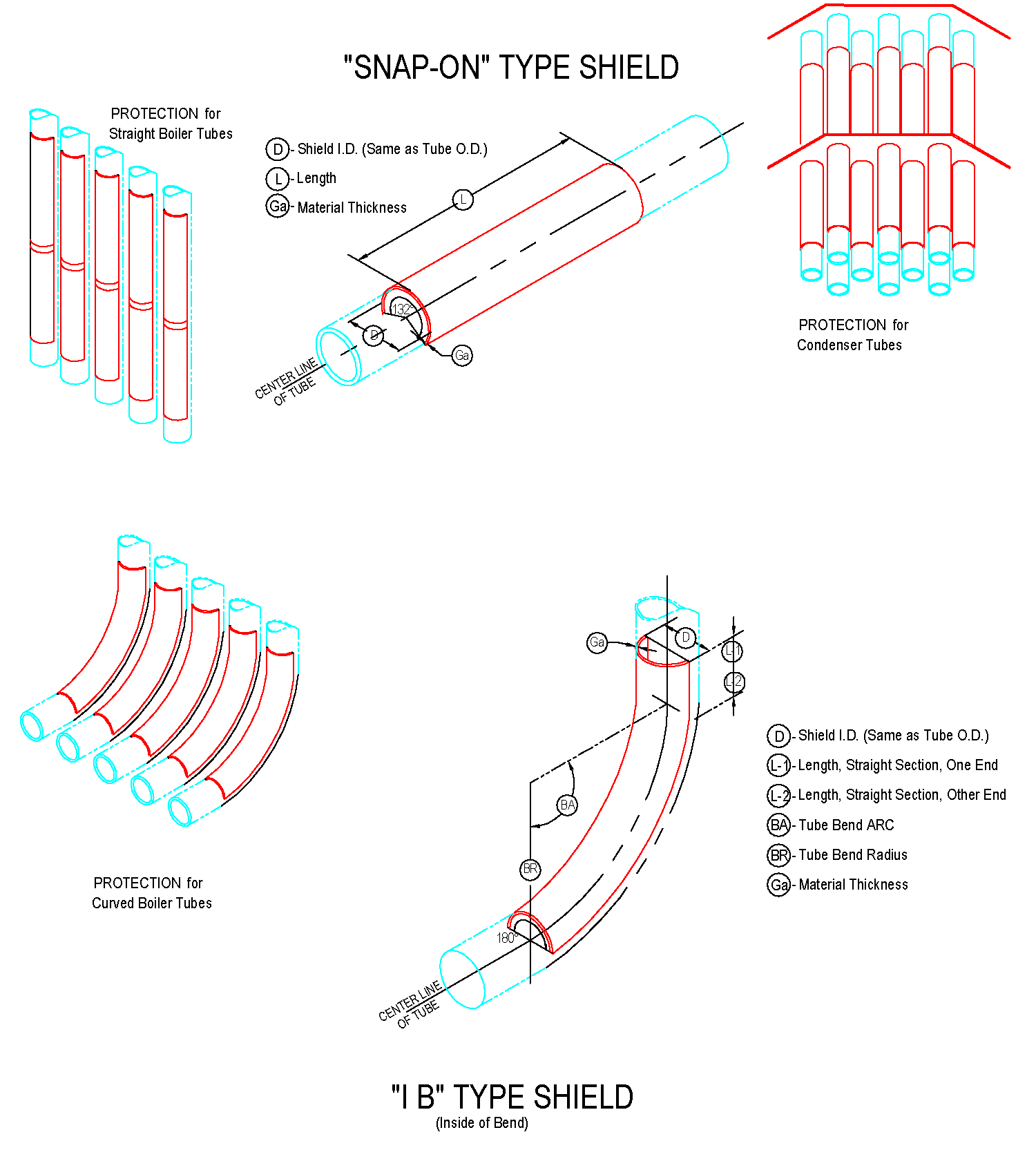

The cross-sectional shape of boiler tubes shields is mostly semi-circular (180 degrees), and there are also 120-160 degrees.

It is mainly used on finned tubes (water-cooled walls); boiler tube erosion shields are divided into direct wear-resistant shields, in-curve, anti-wear shields, outer-curve, anti-wear shields, side-curve anti-wear shields, s-curve anti-wear shields, etc.

The length of the straight anti-wear shields ranges from 20mm to 3000mm, and the general length of 1000-2000mm is commonly used. The anti-wear shields with bends generally requires a processing drawing and the following parameters should be on the drawing: outer diameter of the pipe used, bending of the pipe Radius R (to the center of the pipe), the degree of bending angle, and the length of the straight sections on both sides of the arc segment of the wear-resistant shields.

The most basic parameter of boiler tubes shields is the outer diameter of the tube used (that is, the inner diameter of boiler tubes erosion shields). The main specifications of the tube are: 32, 38, 42, 44.5, 48, 51, 57, 60, 63.5 , 76, 89mm, etc . the inner diameter of the boiler tubes erosion shields is usually 1-3mm larger than the outer diameter of the tube used, depending on the actual requirements.

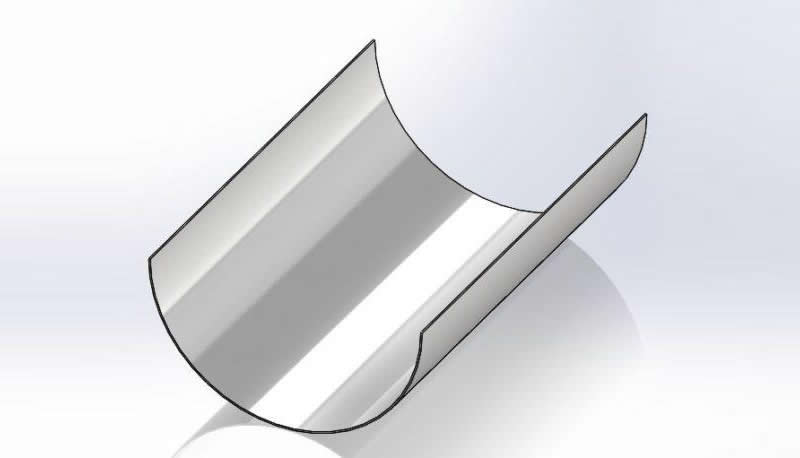

The current production process for tube shields is to use high-pressure presses and professional moulds for pressing.

Tube shields from us are manufactured to exacting standards. Advanced equipment and material handling capabilities permit us to offer the fastest turnaround times anywhere.

The current production process for tube shields is to use high-pressure presses and professional moulds for pressing.

The production time is short, the welding performance is good, the welding seam does not fall off, the surface is smooth and the appearance is beautiful. The arc-shaped wear-resistant tile is pressed on a press or bent on a pipe bender with a special mould.

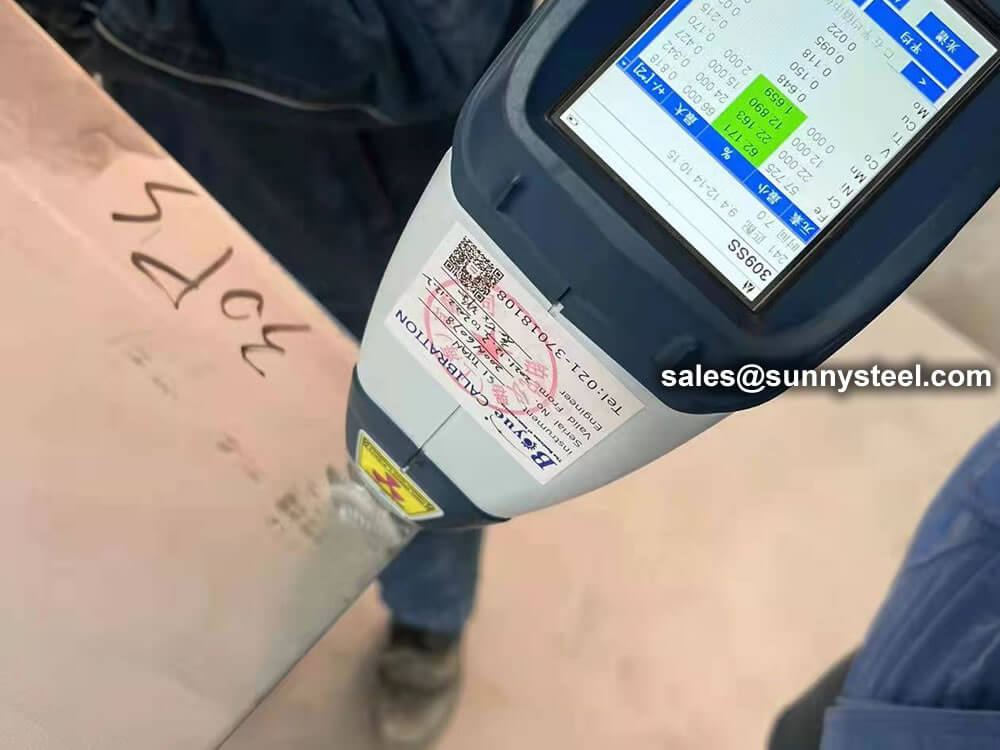

To ensure the accuracy of the material. Positive Material Identification (PMI) of stainless steel sheets for tube shields is critical to verifying the grade and composition of stainless steel before it goes into production.

The raw materials for the production of tube shields are generally purchased directly from standard steel mills, and each batch has an MTC. Due to the sharpe limitations of raw materials, it is inevitable that excess materials will be produced. We can use the excess material to make a smaller size snap ring.

Different types of stainless steel are selected according to the specific conditions of different working conditions.

Common materials are: TP321 (Cr18Ni9Ti), TP309S (Cr23Ni13), 1Cr20Ni14Si2, TP310S (Cr25Ni20), 1Cr25Ni20Si2, and some low temperature areas (such as low temperature superheater, low temperature reheater) are made of 1Cr13, 1Cr6Si2Mo and other materials.

The boiler was originally designed to be accurate. Different materials have different temperature resistance and mechanical strength. 1Cr13, 1Cr6Si2Mo generally has a temperature resistance of 600 ℃ or less.

| Material(Grade) | Temperature resistance | Yield strength | Tensile strength | Elongation | HB | HRB | HV |

|---|---|---|---|---|---|---|---|

| 1Cr18Ni9Ti | 925 ℃ | ≥205MPa | ≥520MPa | ≥40% | ≤187 | ≤90 | ≤200 |

| Cr23Ni13 | 1095 ℃ | ≥205MPa | ≥520MPa | ≥40% | ≤187 | ≤90 | ≤200 |

| 1Cr20Ni14Si2 | 1095 ℃ | --- | ≥590MPa | ≥40% | --- | --- | --- |

| Cr25Ni20 | 1150 ℃ | ≥205MPa | ≥520MPa | ≥40% | ≤187 | ≤90 | ≤200 |

| 1Cr25Ni20Si2 | 1150 ℃ | --- | ≥540MPa | ≥35% | --- | --- | --- |

We can also supply boiler tubes erosion shields of other materials.

Tube shields are custom made to fit perfectly to straight sections, curved sections and even finned and specialised tubing.

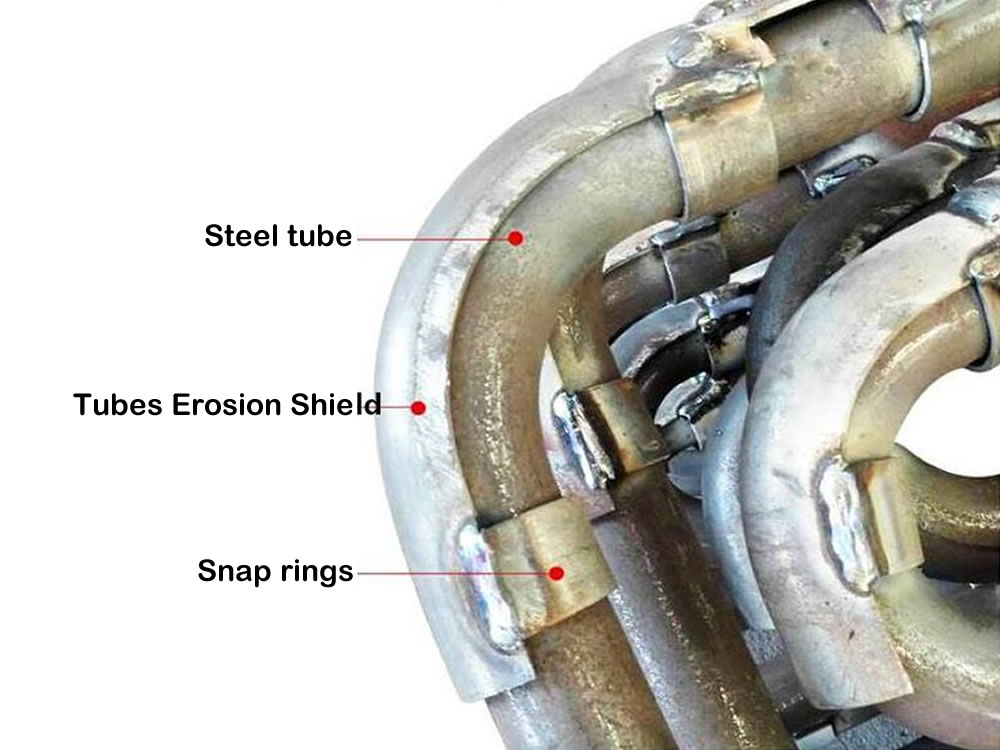

Boiler tube erosion shields, also known as anti-corrosion shields, anti-wear plate, anti-wear protection shields, anti-wear cover plate, anti-corrosion cover plate, boiler climbing pipe, anti-wear pressure plate, etc. , which are used in combination with snap rings.

Boiler tube erosion shields are produced using a high-pressure press and professional mould pressing. The production time is short, the welding performance is good, the welding should not fall off, the surface is smooth, and the appearance is beautiful. Boiler tube erosion shields with bends are formed by pressing on a press or bending with a special abrasive on a tube bender.

Boiler tube shields are designed to eliminate major maintenance and downtime costs from boiler and condenser tube failure.

The service life of boiler tubes erosion shields is different in different types of boilers and different use parts.

The normal service life is a period of overhaul (3-5 years) for the boiler. Generally, some boilers will be replaced or retrofitted every time the boiler is overhauled. The main replacements are those of the Boiler Tubes Erosion Shields that are severely thinned and exceeded the standard; those that were not firmly detached during the boiler operation during the previous installation. According to the wear of the Boiler Tubes Erosion Shields during replacement, if the thickness is severely reduced, it needs to be replaced, the deformation is severe, and those that cannot protect the tube also need to be replaced. In addition, some boiler tubes are not equipped with Boiler Tubes Erosion Shields, but during the boiler inspection, it is found that the tubes have a tendency of wear and thinning. Generally, Boiler Tubes Erosion Shields are also installed to prevent further wear of the tubes and cause serious consequences such as boiler explosion.

On the heating surface of superheater and economizer tube bundle of the boiler, in order to prevent the pipe from being worn by high temperature flue gas washing, boiler tubes erosion shields are mostly arranged on the outer side of the pipe in the direction of flue gas flow. The elbow erosion shields solves the abrasion problems of water wall tubes, superheater tubes, economizer tubes and reheater tubes in the furnace, and provides guarantee for the long-term and reliable operation of CFB boiler. With the increase of CFB boiler products, the type and quantity of The elbow erosion shields will increase.

Our understanding of and commitment to the steam and power generation business enables us to solve your boiler tube erosion or corrosion problems efficiently. Our technical staff can quickly recommend the proper material type and configuration to meet your needs…and can quote your outage delivery requirements on a month basis.

Do you accept a special order?

A: Yes, we do. We can manufacture all kinds of chemical equipments according to your technical drawings(Before you givethem to us, will sign the contract and confidentiality agreement with you. You don’t need to worry about that.)

Can you make a design for us?

A: Yes, we can. What we supply is not only product, but also solution and design. And if you make the product in our factory,the design will be free. If not, design fees will be charged accordingly.

Q: Do you provide after-sales service?

A: Yes, we do. This product is guaranteed up to one year from purchase unless manmade damage. If there is anything wrongwith product itself quality problem,we will change or repair it at our charge.If not, we will provide aftersales service at your charge.

Tube erosion shields are mainly used on the windward side of the heating surface of the boiler, such as superheaters, reheaters, economizers, and water-cooled wall pipes.

Erosion shields are used to protect boiler tubing from the highly erosive effects of high temperatures and pressures thereby greatly extending tube life.

We offer shielding for tubing, covering straight, bent and finned sections, as well as the clips that hold these in place.

In the long term, these shields more than pay for themselves, preventing the costly replacement of tubing and avoiding the downtime that results from tube breakdown and leaks.

In general, most of them are called “wear-resistant tile” and “wear-resistant cover plate”. Erosion Shields are special boiler accessories.

Generally, most of them are used in power station boilers, small boilers are used less, and some coal chemical industries will also use them.

The main role is to protect the heating surface of the boiler pipes, reduce pipeline wear, and increase the heating surface of the pipes.

Generally, boiler tubes erosion shields are also installed to prevent further wear of the tubes and cause serious consequences such as boiler explosion.

The main role is to protect the heating surface of the boiler pipes, reduce pipeline wear, and increase the heating surface of the pipes.

The snap ring is a short section that is installed on the pipe in conjunction with the wear-resistant tile. Generally, it is welded to the wear-resistant tile by lap welding, that is, to cover the wear-resistant tile slightly, so it is larger than the wear-resistant tile. The opening arc is around 190-200 degrees, the welding position needs to be set aside to facilitate welding and fixing. The width of the snap ring must not be less than 20mm.

The installation requirements of anti-friction tiles of different shapes are slightly different. Basically, each anti-friction tile is installed with not less than 2-4 snap rings. The snap ring and the anti-friction tile are welded together to prevent expansion due to heat. The tiles fall off, and the joints are required to be fully welded.

Generally, boiler tubes erosion shields are also installed to prevent further wear of the tubes and cause serious consequences such as boiler explosion.

The main role is to protect the heating surface of the boiler pipes, reduce pipeline wear, and increase the heating surface of the pipes.