Finned tube shields reduce excess wear of fin tubes tubes within the extreme conditions prevalent inside a fossil fuel fired boiler, we are able to manufacture and supply erosion shield solutions to protect and reduce wear in all applicable boiler related situations.

Download PDFFinned tube shields to suit any diameter tube can be manufactured from various alloy and stainless steel materials.

Finned Tube Shields are used in boilers to protect the tubes from high temperatures and pressures that can cause erosion. These shields are designed to extend the life of the tubes and reduce maintenance costs associated with tube failure. They are typically made from materials like stainless steel and are custom-made to fit various tube sizes and configurations, including straight, curved, and finned sections.

Common materials for finned tube shields include:

Finned tube shields are primarily used on the windward side of the heating surface of boilers, such as superheaters, reheaters, economizers, and water-cooled wall pipes. They protect boiler tubing from the highly erosive effects of high temperatures and pressures, thereby greatly extending tube life.

The service life of boiler tube shields varies depending on the type of boiler and the specific parts used. Typically, the service life is about 3-5 years, which coincides with the overhaul period of the boiler. During this period, shields that are severely thinned or damaged may need to be replaced.

Finned tube shields are installed to prevent further wear of the tubes and to avoid serious consequences such as boiler explosions. The shields are usually installed with snap rings, which are used in conjunction with the shields to secure them to the tubes.

Finned tube shields are an essential component in boiler systems, providing protection against erosion and extending the life of the tubes. They are available in various materials and can be customized to fit different boiler configurations. The use of these shields can lead to significant economic benefits by reducing maintenance costs and downtime.

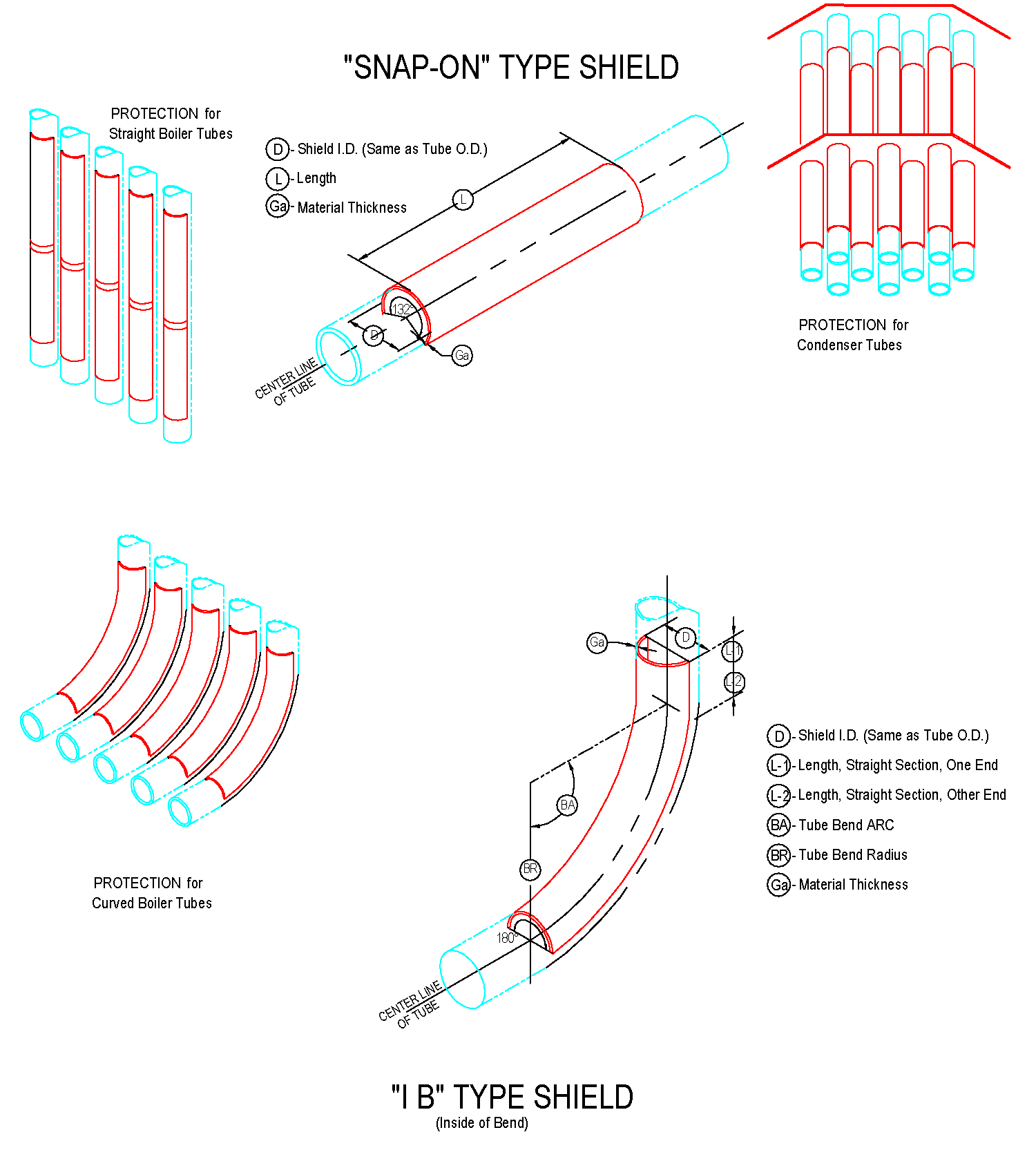

The cross-sectional shape of boiler tubes shields is mostly semi-circular (180 degrees), and there are also 120-160 degrees.

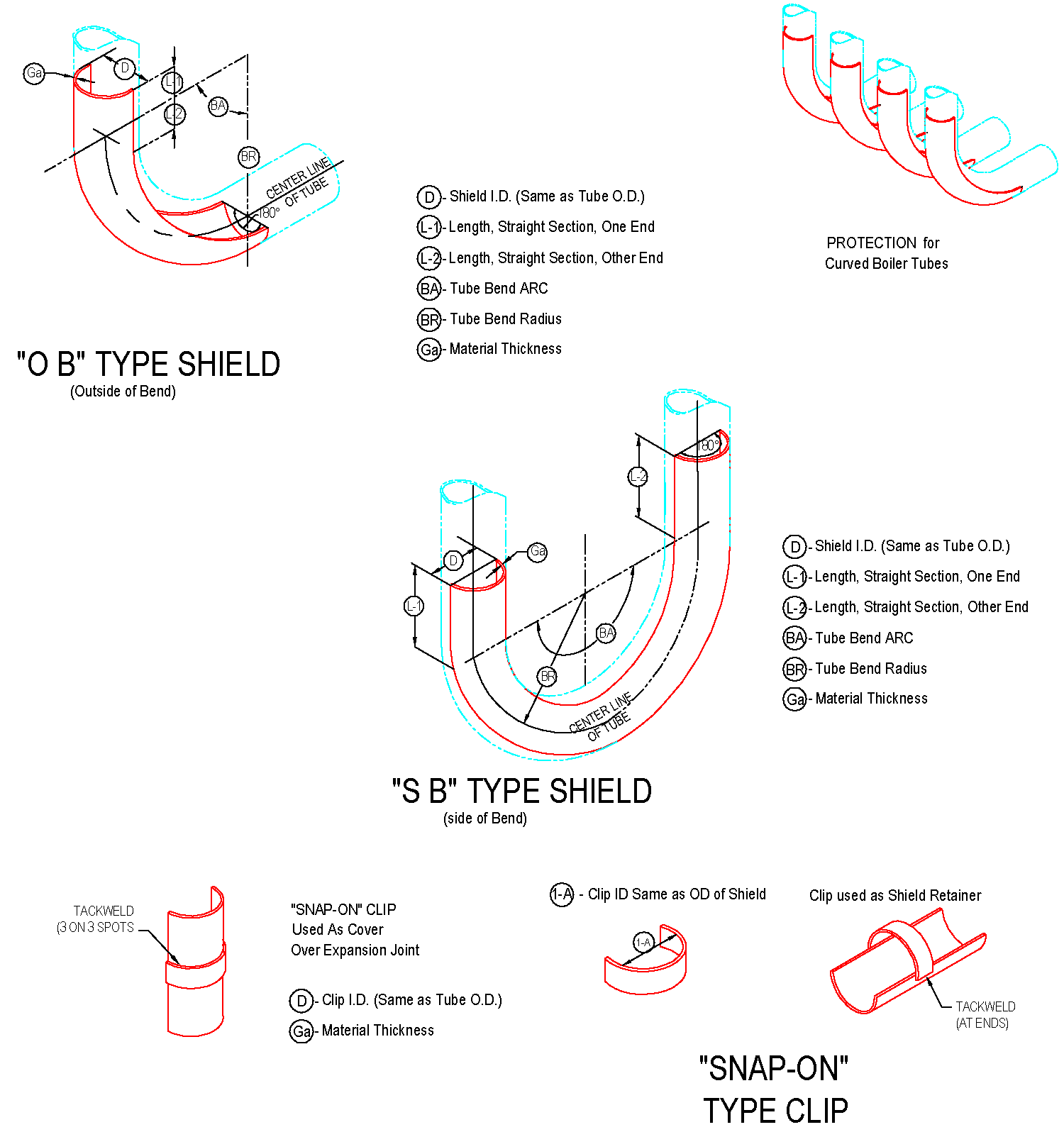

It is mainly used on finned tubes (water-cooled walls); boiler tube erosion shields are divided into direct wear-resistant shields, in-curve, anti-wear shields, outer-curve, anti-wear shields, side-curve anti-wear shields, s-curve anti-wear shields, etc.

The length of the straight anti-wear shields ranges from 20mm to 3000mm, and the general length of 1000-2000mm is commonly used. The anti-wear shields with bends generally requires a processing drawing and the following parameters should be on the drawing: outer diameter of the pipe used, bending of the pipe Radius R (to the center of the pipe), the degree of bending angle, and the length of the straight sections on both sides of the arc segment of the wear-resistant shields.

The most basic parameter of boiler tubes shields is the outer diameter of the tube used (that is, the inner diameter of boiler tubes erosion shields). The main specifications of the tube are: 32, 38, 42, 44.5, 48, 51, 57, 60, 63.5 , 76, 89mm, etc . the inner diameter of the boiler tubes erosion shields is usually 1-3mm larger than the outer diameter of the tube used, depending on the actual requirements.

Generally, boiler tubes erosion shields are also installed to prevent further wear of the tubes and cause serious consequences such as boiler explosion.

The main role is to protect the heating surface of the boiler pipes, reduce pipeline wear, and increase the heating surface of the pipes.