Comb-shaped boiler tube shields are protective devices designed to shield boiler tubes from the harsh conditions prevalent in boiler environments.

These shields are strategically installed around the boiler tubes to create a barrier that minimizes direct exposure to intense heat and combustion byproducts.

Download PDF

1. Heat Resistance: Comb-shaped shields are engineered with materials that exhibit excellent resistance to high temperatures, ensuring that the boiler tubes remain protected during prolonged exposure to heat.

2. Corrosion Protection: The shields act as a barrier against corrosive elements, preventing corrosion-related damage to the boiler tubes and extending their lifespan.

3. Erosion Prevention: Boiler tubes are often subjected to abrasive particles and fly ash, leading to erosion. The comb-shaped design of these shields helps deflect these particles away from the tubes, reducing erosion and maintaining tube integrity.

4. Enhanced Efficiency: By safeguarding the boiler tubes, comb-shaped shields contribute to the overall efficiency of the boiler, as they help maintain a stable and uniform heat transfer process.

5. Easy Installation and Maintenance: Comb-shaped boiler tube shields are designed for easy installation and maintenance, allowing for efficient inspections and replacements, if required.

Comb-shaped boiler tube shields are widely used in various types of boilers, including:

1. Industrial Boilers: These shields are commonly employed in industrial boilers used in manufacturing, chemical processing, and food processing industries.

2. Power Generation Boilers: Comb-shaped shields play a crucial role in power plant boilers, ensuring continuous and efficient electricity generation.

3. Heating Systems: Many heating systems, such as district heating and large-scale heating applications, rely on comb-shaped boiler tube shields to maintain optimal performance.

The proper installation of comb-shaped boiler tube shields is essential to ensure comprehensive coverage and maximum protection for the boiler tubes. Regular inspections and maintenance are crucial to monitor the condition of the shields and address any signs of wear or damage promptly.

Comb-shaped boiler tube shields offer a cost-effective and efficient solution to protect boiler tubes from the harsh conditions of boiler environments. With their ability to resist high temperatures, corrosion, and erosion, these shields significantly contribute to enhancing boiler efficiency and extending the lifespan of boiler tubes. Proper installation and regular maintenance of comb-shaped shields are vital to ensure the continued reliable performance of boilers across various industries.

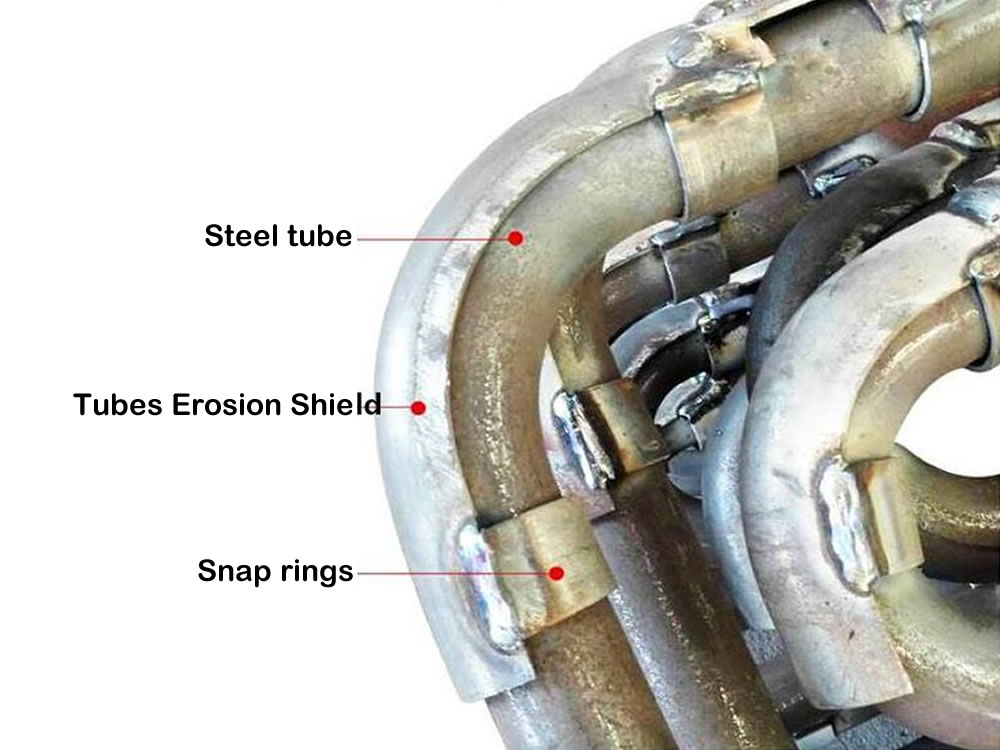

Generally, boiler tubes erosion shields are also installed to prevent further wear of the tubes and cause serious consequences such as boiler explosion.

The main role is to protect the heating surface of the boiler pipes, reduce pipeline wear, and increase the heating surface of the pipes.

The snap ring is a short section that is installed on the pipe in conjunction with the wear-resistant tile. Generally, it is welded to the wear-resistant tile by lap welding, that is, to cover the wear-resistant tile slightly, so it is larger than the wear-resistant tile. The opening arc is around 190-200 degrees, the welding position needs to be set aside to facilitate welding and fixing. The width of the snap ring must not be less than 20mm.

The installation requirements of anti-friction tiles of different shapes are slightly different. Basically, each anti-friction tile is installed with not less than 2-4 snap rings. The snap ring and the anti-friction tile are welded together to prevent expansion due to heat. The tiles fall off, and the joints are required to be fully welded.

Generally, boiler tubes erosion shields are also installed to prevent further wear of the tubes and cause serious consequences such as boiler explosion.

The main role is to protect the heating surface of the boiler pipes, reduce pipeline wear, and increase the heating surface of the pipes.