Stainless 304 Erosion Shield Clamp offers superior protection against erosion and corrosion for boiler tubes and industrial piping systems, ensuring extended service life.

It is crafted from 1Cr6Si2Mo, a martensitic heat-resistant steel, known for its superior oxidation resistance and mechanical strength at elevated temperatures.

The Stainless 304 Erosion Shield Clamp is a high-performance solution designed to protect boiler tubes and piping systems from erosion and corrosion. Made from durable 304 stainless steel, this clamp ensures a secure fit while providing long-lasting protection in demanding industrial environments.

There are hundreds of different grades of stainless steel on the market. Each of these unique formulations of stainless steel offer some degree of corrosion resistance above and beyond that of plain steel.

The existence of these stainless steel variants can cause some confusion—especially when the names & formulations of two stainless steel alloys are almost the same. This is the case with grade 304 and 304L stainless steel.

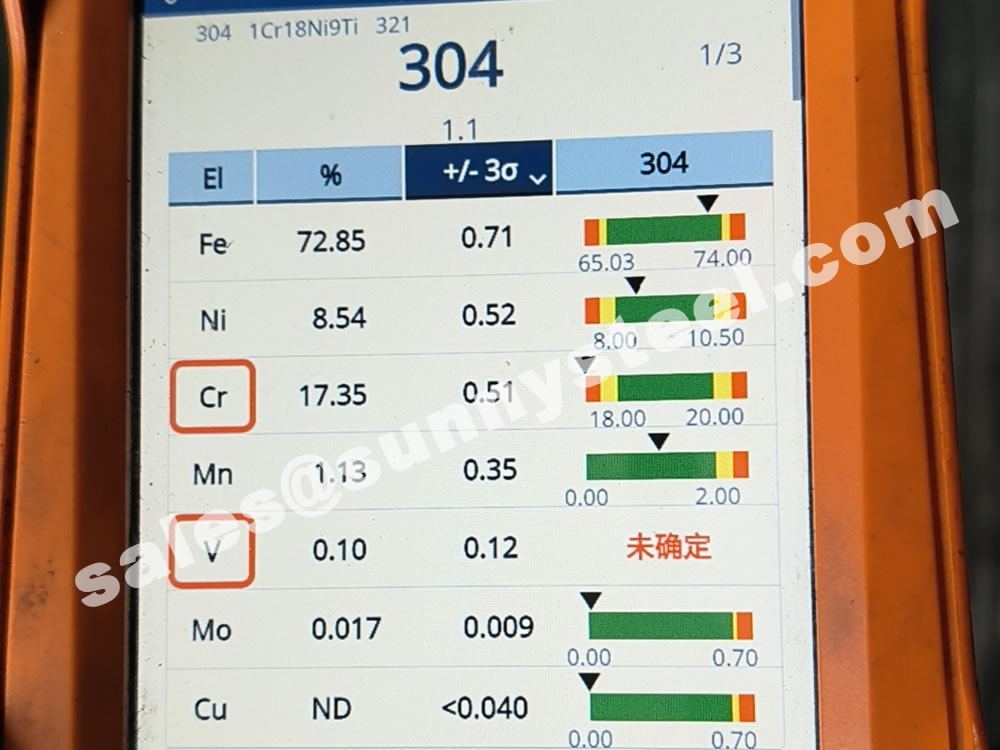

| Element | Percentage by Weight Maximum Unless Range is Specified | ||

|---|---|---|---|

| 304 | 304L | 304H | |

| Carbon | 0.08 | 0.030 | 0.04-0.10 |

| Manganese | 2.00 | 2.00 | 2.00 |

| Phosphorus | 0.045 | 0.045 | 0.045 |

| Sulfur | 0.030 | 0.030 | 0.030 |

| Silicon | 0.75 | 0.75 | 0.75 |

| Chromium | 18.00 20.00 |

18.00 20.00 |

18.00 20.00 |

| Nickel | 8.0 10.50 |

8.0 12.00 |

8.0 10.5 |

| Nitrogen | 0.10 | 0.10 | 0.10 |

These three alloys are remarkably similar—but there is one key difference. In grade 304 stainless, the maximum carbon content is set at 0.08%, whereas grade 304L stainless steel has a maximum carbon content of 0.03%. The “L” in 304L can be interpreted as meaning extra-low carbon.

This difference of 0.05% carbon content produces a slight, but marked, difference in the performances of the two alloys.

| Grade | Tensile Strength Rm N/mm² |

Yield Strength Rp 0.2, N/mm² | Elongation (%) |

|---|---|---|---|

| 304 Annealed | 500-700 | 195 | 40 |

| 304L Annealed | 460-680 | 180 | 40 |

| Data | Metric | English |

|---|---|---|

| Density | 8 g/cc | 0.289 lb/in³ |

| Hardness, Brinell | 123 | 123 | Converted from Rockwell B hardness. |

|---|---|---|---|

| Hardness, Knoop | 138 | 138 | Converted from Rockwell B hardness. |

| Hardness, Rockwell B | 70 | 70 | |

| Hardness, Vickers | 129 | 129 | Converted from Rockwell B hardness. |

| Tensile Strength, Ultimate | 505 MPa | 73200 psi | |

| Tensile Strength, Yield | 215 MPa | 31200 psi | at 0.2% offset |

| Elongation at Break | 70 % | 70 % | in 50 mm |

| Modulus of Elasticity | 193 - 200 GPa | 28000 - 29000 ksi | |

| Poissons Ratio | 0.29 | 0.29 | |

| Charpy Impact | 325 J | 240 ft-lb | |

| Shear Modulus | 86 GPa | 12500 ksi |

| Electrical Resistivity | 7.2e-005 ohm-cm | 7.2e-005 ohm-cm | at 20°C (68°F); 1.16E-04 at 650°C (1200°F) |

| Magnetic Permeability | 1.008 | 1.008 | at RT |

Grade 304L has a slight, but noticeable, reduction in key mechanical performance characteristics compared to the “standard” grade 304 stainless steel alloy.

Typical specifications for 304 Plate and 304L Stainless Steel Plate are ASTM A-240, ASME SA -240 and A666.

304 stainless steel,also known as 18/8 stainless steel, European norm 1.4301, is the most common stainless steel. The steel contains both chromium (usually 18%) and nickel (usually 8%) metals as the main non-iron constituents. It is an austenite steel. It is not very electrically or thermally conductive, and is non-magnetic. It has a higher corrosion resistance than regular steel and is widely used because of the ease in which it is formed into various shapes.

Grade 304L is the low carbon version of 304. It does not require post-weld annealing and so is extensively used in heavy gauge components.

Design Features - Stainless Steel 304/304L

Typical Applications - Stainless Steel 304/304L

Tensile Requirements - Stainless Steel 304/304L

304 Stainless Steel Plate has very good formability and can be readily welded by all common methods.

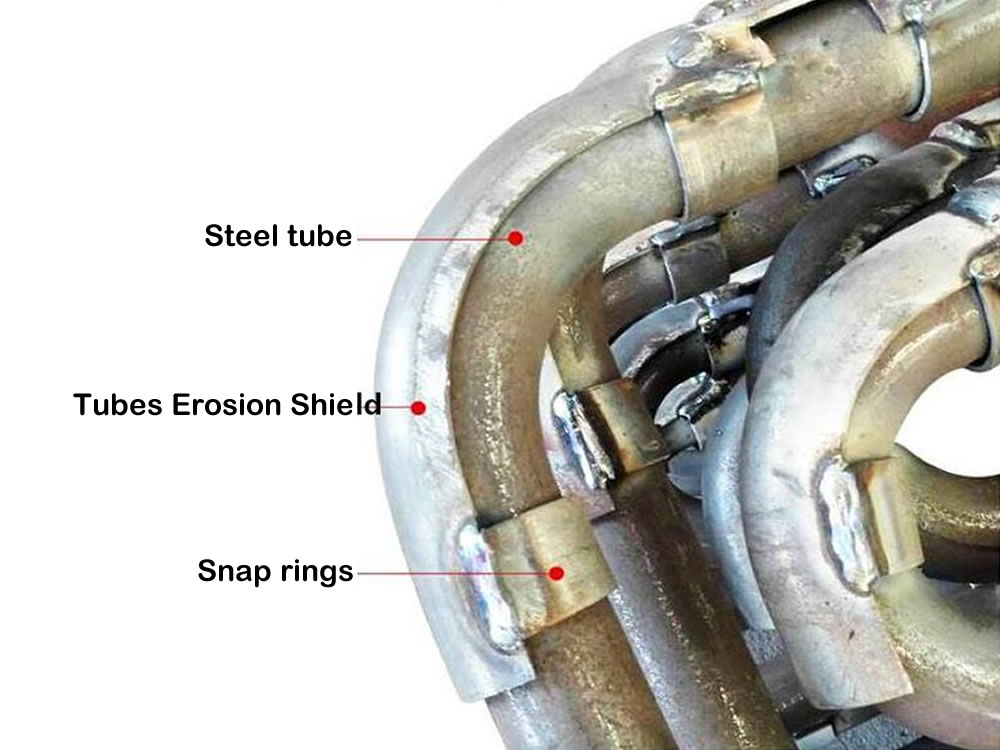

Our precision machinery and state of the art facilities enables us to produce these 304 tube shield in superior quality and precise dimensions. All these years have enhanced our capabilities and enabled us to produce all kinds of standard tube shield as well as custom snap rings as per customer’s specifications. We have numerous combinations of sizes readily available in large number of stocks and can fabricate custom sizes according to customer’s requirement.

In common with other austenitic stainless steels, 304 grade has strong work hardening characteristics. Clearly, in some cases, this can be an advantage, but generally, it is an issue to be considered carefully.

If it is likely to be an issue, discussion with the producer can be valuable as minor variations to the precise composition and process can have benefits.

Where heavy sections have to we welded, post-weld annealing may be necessary to restore corrosion resistance.

The cross-sectional shape of boiler tube erosion shields is mostly semi-circular (180 degrees), and there are also 120-160 degrees. It is mainly used on finned tubes (water-cooled walls); boiler tubes erosion shields are divided into direct wear-resistant shields, in-curve anti-wear shields, outer-curve anti-wear shields, side-curve anti-wear shields, s-curve anti-wear shields, etc. The length of the straight anti-wear shields ranges from 20mm to 3000mm, and the general length of 1000-2000mm is commonly used. The anti-wear shields with bends generally requires a processing, drawing and the following parameters should be on the drawing: outer diameter of the pipe used, bending of the pipe radius r (to the centre of the pipe), the degree of bending angle, and the length of the straight sections on both sides of the arc segment of the wear-resistant shields.

The most basic parameter of boiler tube erosion shields is the outer diameter of the tube used (that is, the inner diameter of boiler tubes erosion shields). The main specifications of the tube are: 32, 38, 42, 44.5, 48, 51, 57, 60, 63.5 , 76, 89mm, etc .; the inner diameter of the boiler tubes erosion shields is usually 1-3mm larger than the outer diameter of the tube used, depending on the actual requirements.

Alloy 304 a T-300 series stainless steel austenitic, which has a minimum of 18% chromium and 8% nickel. Type 304 has a maximum carbon of 0.07% . It is the standard “18/8 stainless” that is commonly found in pans and cooking tools. Alloy 304 is the most versatile and widely used alloy in the stainless steel family. Ideal for a wide variety of home and commercial applications, Alloy 304 exhibits excellent corrosion resistance and has a high ease of fabrication, outstanding formability. The austenitic stainless steels are also considered to be the most weldable of the high-alloy steels and can be welded by all fusion and resistance welding processes.

Specifications: UNS S30400

The 304 Erosion Shield Connector is crafted from premium-grade stainless steel, ensuring exceptional wear and corrosion resistance. It is engineered for demanding industrial environments, offering a reliable solution to extend the lifespan of critical components in power generation, chemical processing, and other heavy-duty industries.

The 304 Erosion Shield Connector is suitable for:

Tube shields are custom made to fit perfectly to straight sections, curved sections and even finned and specialised tubing.

Boiler tube erosion shields, also known as anti-corrosion shields, anti-wear plate, anti-wear protection shields, anti-wear cover plate, anti-corrosion cover plate, boiler climbing pipe, anti-wear pressure plate, etc. , which are used in combination with snap rings.

Boiler tube erosion shields are produced using a high-pressure press and professional mould pressing. The production time is short, the welding performance is good, the welding should not fall off, the surface is smooth, and the appearance is beautiful. Boiler tube erosion shields with bends are formed by pressing on a press or bending with a special abrasive on a tube bender.

Boiler tube shields are designed to eliminate major maintenance and downtime costs from boiler and condenser tube failure.

Generally, boiler tubes erosion shields are also installed to prevent further wear of the tubes and cause serious consequences such as boiler explosion.

The main role is to protect the heating surface of the boiler pipes, reduce pipeline wear, and increase the heating surface of the pipes.

The snap ring is a short section that is installed on the pipe in conjunction with the wear-resistant tile. Generally, it is welded to the wear-resistant tile by lap welding, that is, to cover the wear-resistant tile slightly, so it is larger than the wear-resistant tile. The opening arc is around 190-200 degrees, the welding position needs to be set aside to facilitate welding and fixing. The width of the snap ring must not be less than 20mm.

The installation requirements of anti-friction tiles of different shapes are slightly different. Basically, each anti-friction tile is installed with not less than 2-4 snap rings. The snap ring and the anti-friction tile are welded together to prevent expansion due to heat. The tiles fall off, and the joints are required to be fully welded.