Stainless U bend tubes

Stainless U bend tubes are made of stainless steel and are bent in a U-shape to redirect the flow of liquids or gases in a piping system.

Titanium alloy U bent tubes are a type of tubing made from titanium alloys that are bent in the shape of a U.

These tubes are commonly used in heat exchangers, condensers, and other applications where efficient heat transfer is required.

Titanium alloys are known for their excellent corrosion resistance, high strength, and lightweight properties, making them suitable for various industrial applications.

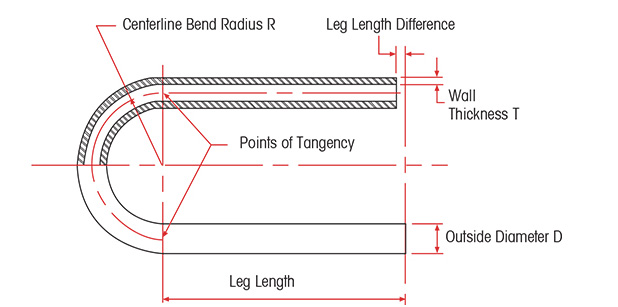

The manufacturing process for titanium alloy U bent tubes typically involves cold working methods. The tubes are bent to the necessary bend radius as per client drawings The specific titanium alloy used may vary depending on the application and the desired properties.

Titanium U Bent tube is carried out by cold working method and is being done to the necessary bend radius as per client drawings. U-bend tube/pipe can be manufactured from an extensive range of pipe materials that contain high and low yield stainless steels, alloy steels, carbon steels,Monel , Inconel, hastelloy,duplex , super duplex,titanium,copper alloy and Cr-Ni alloys. Usually U-bends manufactured from seamless tube, can further be customized in terms of thicknesses and sizes as per the specific requirements of our clients. They are easy for further assemble tube bundles.

We supply U-bend tubes used in various industries for a wide range of applications, including boilers, condensers, evaporators, tube bundles for heat exchangers, coolers, intercoolers, chillers, and more. These tubes are also utilized in different sectors such as fertilizer plants, the sugar industry, steel plants, oil and gas facilities, chemical and petrochemical plants, refineries, power plants, renewable energy installations, and more.

Titanium alloy U bent tubes offer several advantages in heat transfer applications:

Titanium alloy U bent tubes find applications in various industries where corrosion resistance, high strength, and lightweight properties are required. Some common applications include:

Titanium tubing is a type of tubing made from titanium, a metal known for its excellent corrosion resistance, high strength-to-weight ratio, and lightweight properties.

Titanium seamless tube has outstanding corrosion resistance and a combination of high strength and low density, with good ductility. It is also widely used in heat exchanger, condenser, water treatment, desalination, evaporator, and pipelines, etc. We supported the Water pressure test, UT test, X-ray test, Eddy current test, and Customer required test

Titanium welded tubes are tubes made from titanium that have been joined together using a welding process.

Titanium coil tubing

Titanium Alloy Oval Tube

Titanium tubing packing

We packs all U Tube bundles in bespoke wooden boxes and separate all U Tubes of different radii using finger pallets to facilitate easy assembly of bundles on receipt.

Any type of packing is available according to customer need to worldwide destinations.