Stainless U bend tubes

Stainless U bend tubes are made of stainless steel and are bent in a U-shape to redirect the flow of liquids or gases in a piping system.

U bent heat exchanger tubes are a type of heat exchanger tube that has been formed into a U-shape or hairpin shape.

U-bent heat exchanger tubes are used in industrial applications to transfer heat between fluids. They are designed for high temperature applications, such as steam condensing or hot oil systems. U-bent tubes are also used in boilers and condensers.

U-bent tubes are named after the "U" shape of the tube. They are made of stainless steel and transfer heat from a hot to a cold side through the tube. The width of the tubes on each end makes this possible.

U-bent tubes are used in many industries, including:

U bent heat exchanger tubes are used in various industrial applications for heat transfer between fluids, such as in boilers and condensers. U bent heat exchanger tubes are made from a variety of materials including stainless steel, titanium, and copper alloys depending on the application and environmental factors. They are typically designed to withstand high temperatures and pressures and are used in both liquid and gas applications.

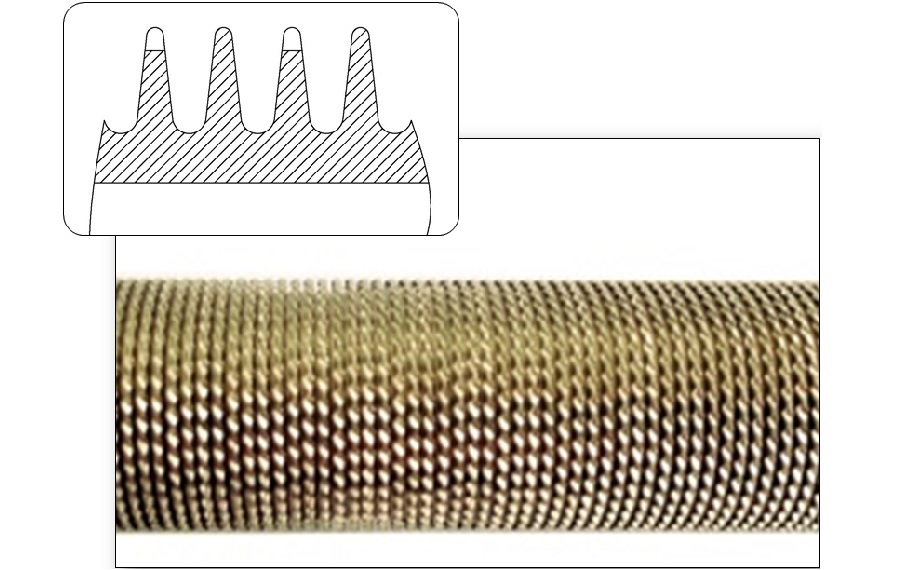

Condenser Tube "Y-fin"

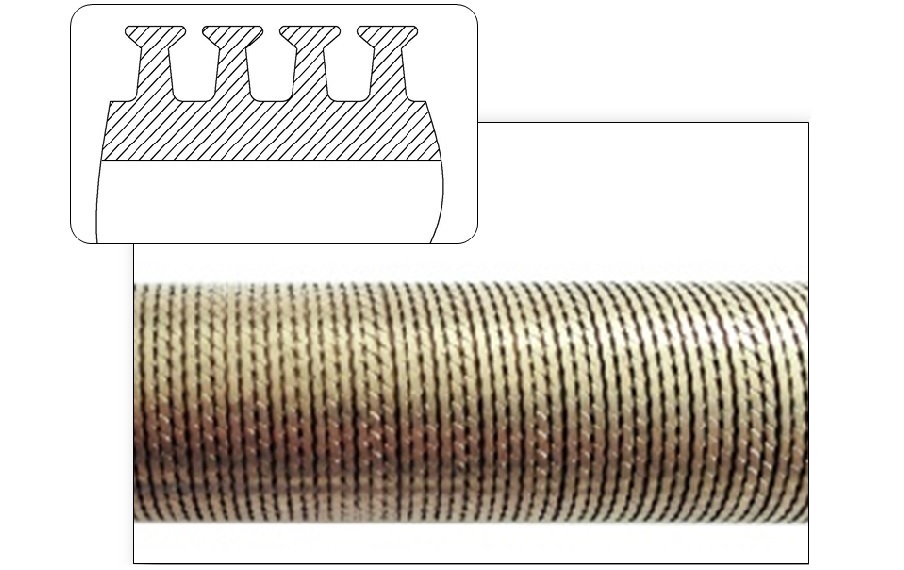

Evaporator Tube "T-fin"

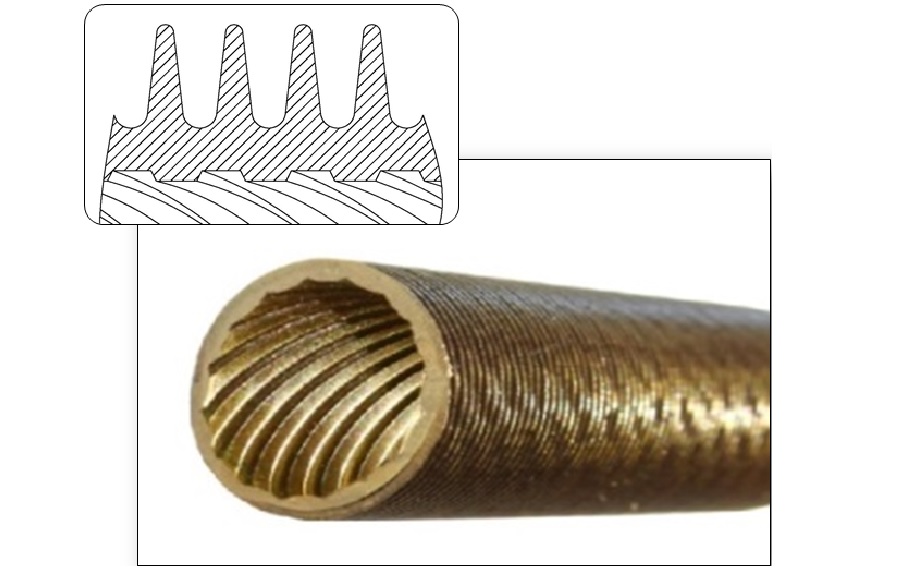

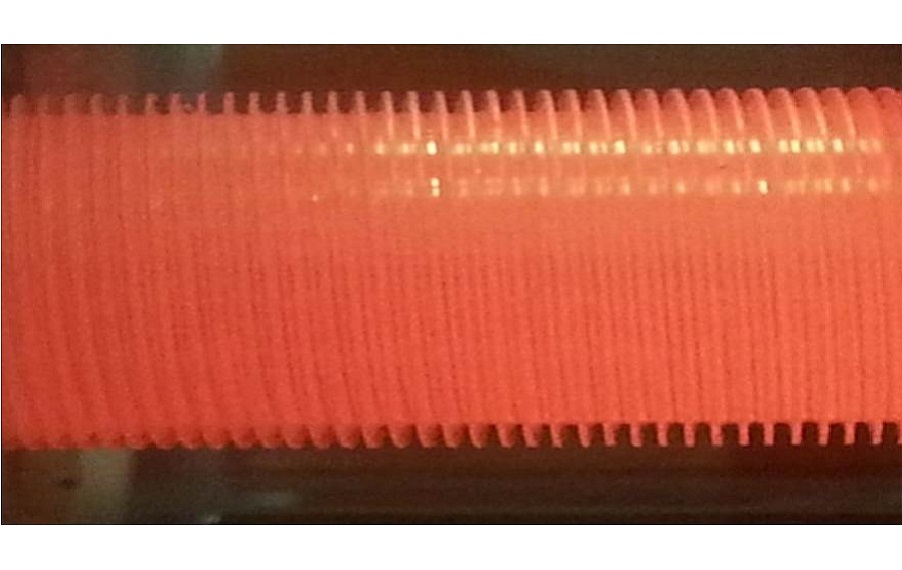

Inner Grooved (IG) Low Fin Tube

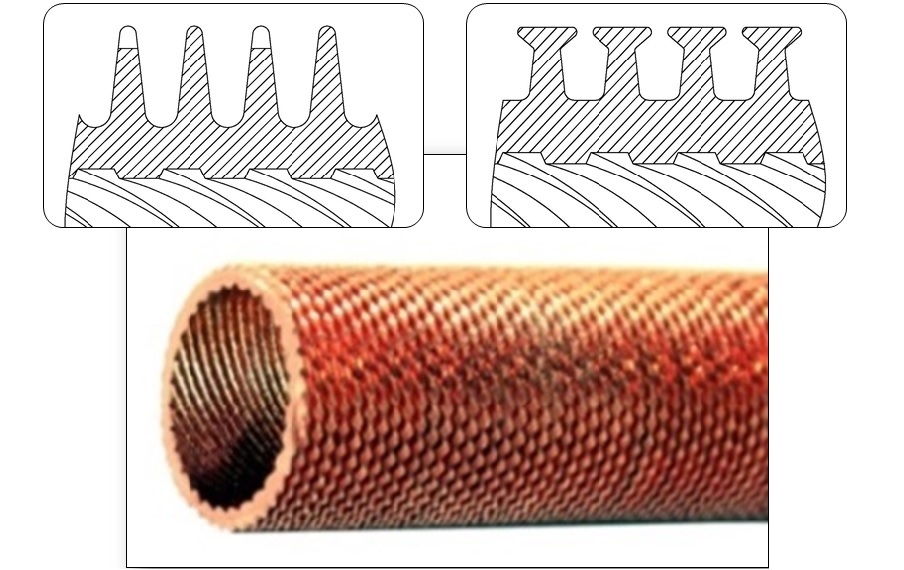

Inner Grooved (IG) Y-Fin / T-fin Tube

U-Bent Low Fin Tube

Annealed Low Fin Tube

The semi-finished product for U bend tubes are heat exchanger tubes, manufactured and supplied according to DIN 28180 and ASTM A179.

Tubes for heat exchangers are made of steel according to:

| Standard | Application |

|---|---|

| ASTM A179 | Seamless Cold-Drawn Low-Carbon Steel Heat-Exchanger and Condenser Tubes |

| ASTM A192 | Seamless Carbon Steel Boiler Tubes for High-Pressure Service |

| ASTM A210 | Seamless Medium-Carbon Steel Boiler and Superheater Tubes |

| ASTM A213 | seamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater, and Heat-Exchanger Tubes |

| ASTM A334 | Seamless Steel Pipe for Low-Temperature Service and other Applications with Required Notch Toughness |

| JIS G3461/2 | carbon steel tubes used for heat exchange in boilers, heat exchangers, condensers, and similar equipment |

| EN10216-1/2 | specified the standard of cold processed precision steel tubes in a wide range of sizes |

| DIN17175 | seamless tubes for high-pressure and high-temperature applications, specifically for boilers and heat exchangers |

| Standard | Grade | Chemical Components (%) | Mechanical Properties | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | P | S | Mo | Cr | V | T.S. (Mpa) | Y.S. (Mpa) | E.L. (%) | Hardness (HRB) | ||

| ASME SA179 | SA179 | 0.06-0.18 | / | 0.27-0.63 | ≤0.035 | ≤0.035 | / | / | / | ≥325 | ≥180 | ≥35 | ≤72 |

| ASME SA192 | SA192 | 0.06-0.18 | ≤0.25 | 0.27-0.63 | ≤0.035 | ≤0.035 | / | / | / | ≥325 | ≥180 | ≥35 | ≤77 | ASME SA210 | A1 | ≤0.27 | ≥0.10 | ≤0.93 | ≤0.035 | ≤0.035 | / | / | / | ≥415 | ≥255 | ≥30 | ≤79 |

| C | ≤0.35 | ≥0.10 | 0.29-1.06 | ≤0.035 | ≤0.035 | / | / | / | ≥485 | ≥275 | ≥30 | ≤89 | |

| ASTM A333 /A334 | GR.1 | ≤0.30 | / | 0.4-1.06 | ≤0.025 | ≤0.025 | / | / | / | ≥380 | ≥205 | ≥35 | -45° |

| GR.6 | ≤0.30 | ≥0.10 | 0.29-1.06 | ≤0.025 | ≤0.025 | / | / | / | ≥415 | ≥240 | ≥30 | -45° | |

| GR.8 | ≤0.13 | 0.13-0.32 | ≤0.90 | ≤0.025 | ≤0.025 | / | / | 8.40-9.60 | ≥690 | ≥515 | ≥22 | -195° | |

U bend tubes for heat exchangers applied mostly in oil and gas plants, chemical and petrochemical plants, refineries, power plants and renewable energy plants. Low fin tubes can be supplied in the form of U bends.

U-bend tubes are widely used in heat-exchanger systems. Heat-exchanger equipment on the basis of seamless stainless U-tubes is essential in strategically important and critical fields — nuclear and petrochemical machine building.

| Item | Condition (when) | Tolerance |

|---|---|---|

| Ovality | Nominal bend radius ≤ 2 x nominal OD | less than or equal to 12% |

| 2 x nominal OD < Nominal bend radius ≤ 4 x nominal OD | less than or equal to 10% | |

| Nominal bend radius > 4 x nominal OD | less than or equal to 5% | |

| Nominal bend radius ≤ 2 x nominal OD | 0.75 x nominal wall | |

| Mimimum wall thickness | 2 x nominal OD < Nominal bend radius ≤ 4 x nominal OD | 0.8 x nominal wall |

| Nominal bend radius > 4 x nominal OD | 0.9 x nominal wall | |

| Nominal bend radius ≤ 8" (200mm) | +/-3/64"(1mm) | |

| Bending Radius | 8" (200mm) < Nominal bend radius ≤ 16" (400mm) | +/-1/16"(1mm) |

| Nominal bend radius >16" (400mm) | +/-5/64"(1mm) | |

| Disrance between legs | Max 1/16"(1.5mm) | |

| Wall thinning of bending area | Max 17% | |

| Difference between leg lengths at the ends | Leg length ≤ 16' (4.88m) | +1/8"(3mm) |

| Leg length > 16' (4.88m) | +3/16"(5mm) | |

| Deviation from plane of bend | ≤ 3/16"(1.5mm) | |

| Flattening on bend | ≤ 10% nominal diameter | |

| Straight leg length | ≤5m | +1/8"(3mm) |

| >5m | +3/16(5mm) | |

| Total tube length including radius | ≤6m | +3/16(5mm) |

| >6m | +5/16"(8mm) |

We packs all U Tube bundles in bespoke wooden boxes and separate all U Tubes of different radii using finger pallets to facilitate easy assembly of bundles on receipt.

Any type of packing is available according to customer need to worldwide destinations.