Stainless U bend tubes

Stainless U bend tubes are made of stainless steel and are bent in a U-shape to redirect the flow of liquids or gases in a piping system.

U Bend Tubing 304L Stainless Steel

Stainless U bend tubes are made of stainless steel and are bent in a U-shape to redirect the flow of liquids or gases in a piping system.

They are commonly used in heat exchanger systems. When shopping for stainless U bend tubes consider the following factors:

Heat exchanger equipment on the basis of stainless steel U-tube is essential in strategically important and critical fields nuclear and petrochemical machine building.

Surface condition Finished U Bend Tube shall be free of scale, without scratches after bending

Heat exchanger tubes can also be delivered as U-bent tube / U bend pipe, manufactured according to the common heat exchanger standards. Our basic specification for u bend pipes is ASTM A213/A213M, ASTM A 312/312M, EN 10216-5, and we can also follow various specifications on customers' requests.

Stainless U bends in the tube help to change the direction of the flow of the medium being transported, which helps to reduce the need for additional piping that would otherwise be required to accomplish the same effect. These tubes are often used in industries where cleanliness and hygiene are critical, such as food and beverage processing, pharmaceuticals, and chemical processes, because stainless steel is non-corrosive and resistant to high temperatures and pressure.

316 stainless steel tubing is durable and has excellent physical properties and resistance to corrosive agents found in automotive exhaust emissions.

We can offer to customize service if customers have more stringent requirements on capillary dimensional accuracy and surface finish, including stainless steel bright annealed pipe,

Bending radius: from 1.5*OD(Outside Diameter) To 1500mm

Material: Stainless Steel, Duplex Stainless Steel

Size O.D: 12.7-38.1mm

Length: 3M-12M or Custom Cut Sizes

304L stainless steel tubing provides great durability by combining excellent physical properties with resistance to corrosive agents found in automotive exhaust emissions. This 304L tubing is made in the USA and is mandrel bent to provide smooth bends to ensure maximum flow. Burns' high standards ensure constant cross sections minimizing labor costs for fabricators.

U Bend Tubing made of 304L stainless steel is a type of tubing that is bent in the shape of a U. It is commonly used in various industries, including oil and gas plants, chemical and petrochemical plants, power generation plants, refineries, and boiler heat exchangers.

304L stainless steel is a specific grade of stainless steel known for its durability and resistance to corrosive agents. It combines excellent physical properties with a remarkable resistance to corrosion. The material is commonly used in applications where resistance to corrosion is essential, such as in harsh environments or when dealing with corrosive substances.

When buying U Bend Tubing 304L Stainless Steel, you can consider things like:

Here are some key points about U Bend Tubing 304L Stainless Steel:

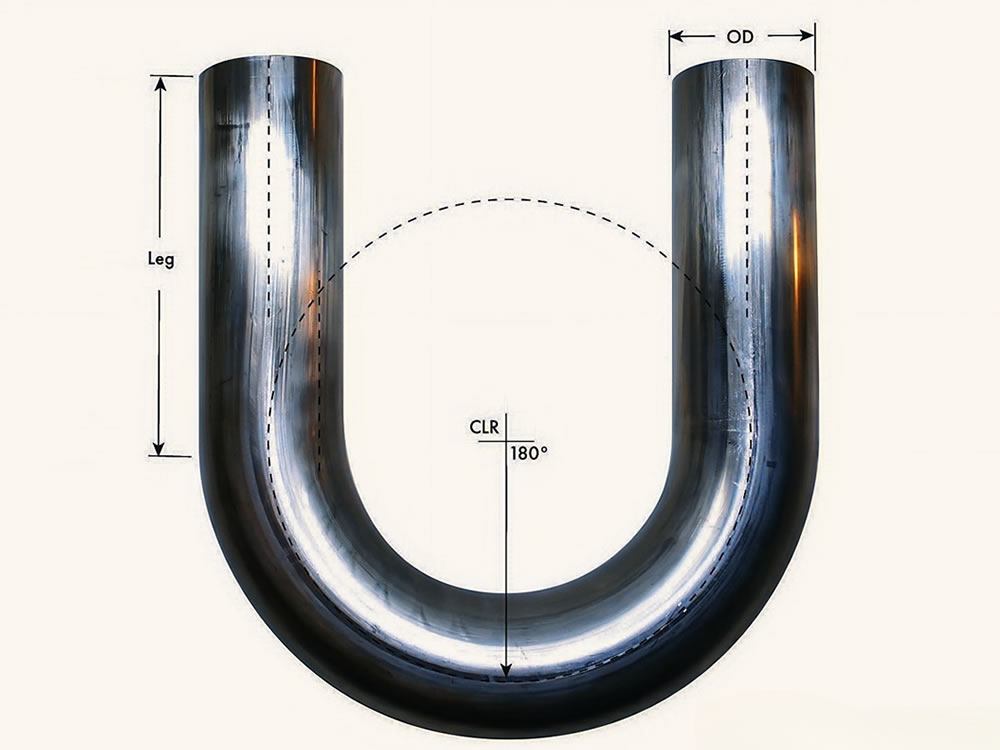

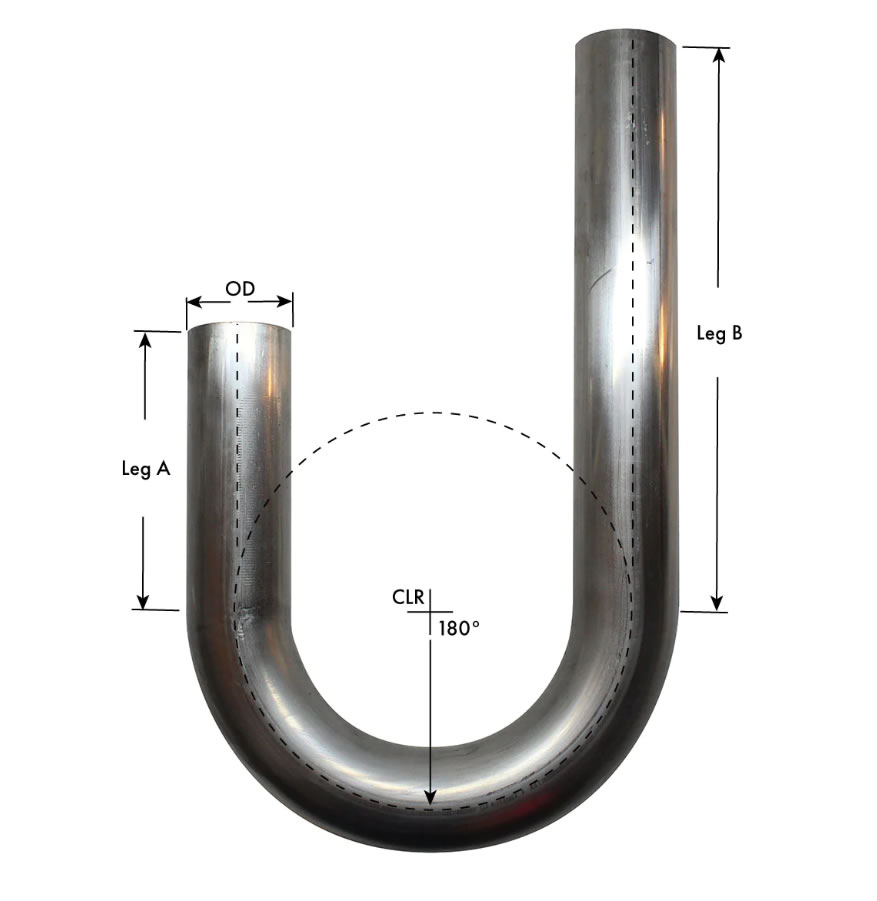

Diameter of tube in the U bent portion

At the bent portion of a U-tube for R = 2 × D or greater, neither the major nor minor diameter of the tube shall deviate from the nominal diameter prior to bending by more than 10 %.

If less than 2 × D is specified, tolerances could be greater, provided that Entropie agrees prior to order.

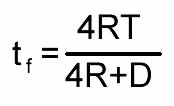

Wall thickness in U bent portion

The wall thickness of the tube in the U-bent section shall not be less than value determined by the equation:

Where:

3.3 Tube leg length

In the case of U-tubes, the length of the tube legs as measured from the point of tangency of the bend and the tube leg to the end of the tube leg, shall not be less than specified, but may exceed the specified values by the amount given here below :

Leg length [mm]

Up to and incl. 6000 mm : -0 / +3.2 mm

Over 6000 mm to 9000 (incl) : -0 / +4.0 mm

Over 9000 -0 / + 4.8 mm

3.4 Difference in leg length

Stainless Steel Tube U Bend | U Bend Heat Exchanger TubesThe difference in lengths of the tube legs of a U tube shall not be greater than 1⁄8 in. = 3.2 mm unless otherwise specified.

End of tube : squareness

The end of any tube may depart from square by not more than:

0.25 mm for tubes up to 5/8” [15.9 mm]

0.40 mm for tubes higher than 5/8” [15.9 mm]

Leg spacing

The leg spacing measured between the points of tangency of the bend to the legs shall not vary from the value (2 R − specified tube outside diameter) by more than 1⁄16 in.[1.5 mm] where R is the center-line bend radius.

Bent portion curvature

The bent portion of the U-tube shall be substantially uniform in curvature, and not to exceed 6 1⁄16 in. [1.5 mm] of the nominal center-line radius.

Deviation from the plane of bend

Permissible deviation from the plane of bend (Fig. 1) shall not exceed 1⁄16 in. [1.5 mm] as

measured from the points of tangency.

The dimensions for heat exchanger tube in special grades may differ from the above,please contact us.

The advantage of the shell and tube design cannot be ignored. Each unit comes with:

The most common grades used for stainless steel tube bending include 304 stainless steel and 316 stainless steel. The material grade you choose determines the type of bending process used along with the radius that can be achieved without damaging the tube.

U-bend tubes are used to transfer heat between fluids. They can return the flow of coolants/fluids at 180 degrees in a much smaller space.

The common application fields are: heat exchangers (condensers, evaporators, sea water desalinators) chemical and petrochemical industries. food processing and refrigeration industries.

Heat-exchanger equipment on the basis of seamless stainless U-tubes is essential in strategically important and critical fields — nuclear and petrochemical machine building.

Fin tubes are used in applications involving the transfer of heat from a hot fluid to a colder fluid through a tube wall. Furthermore, finned tubes are used when the heat transfer coefficient on the outside of the tubes is appreciably lower than that on the inside.

As the pipes warm up they expand, the bend allows this expansion to proceed without buckling the pipes. Alternatively, flexible or sliding types of expansion provision are available, and large pipes are mounted on rollers.

With strong wood structure box packing by containers loading and shipping.

| Type | Grade | Grade | Chemical Component % | ||||||||||

| C | Cr | Ni | Mn | P | S | Mo | Si | Cu | N | Other | |||

| Austenitic | 201 | SUS201 | ≤0.15 | 16.00-18.00 | 3.50-5.50 | 5.50-7.50 | ≤0.060 | ≤0.030 | - | ≤1.00 | - | ≤0.25 | - |

| 304 | 1.4301 | ≤0.07 | 17.00-19.00 | 8.00-10.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 304L | 1.4307 | ≤0.030 | 18.00-20.00 | 8.00-10.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 304H | 1.4948 | 0.04-0.10 | 18.00-20.00 | 8.00-10.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 309 | 1.4828 | ≤0.20 | 22.00-24.00 | 12.00-15.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 309S | * | ≤0.08 | 22.00-24.00 | 12.00-15.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 310 | 1.4842 | ≤0.25 | 24.00-26.00 | 19.00-22.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.50 | - | - | - | |

| 310S | * | ≤0.08 | 24.00-26.00 | 19.00-22.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.50 | - | - | - | |

| 314 | 1.4841 | ≤0.25 | 23.00-26.00 | 19.00-22.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | 1.50-3.00 | - | - | - | |

| 316 | 1.4401 | ≤0.08 | 16.00-18.50 | 10.00-14.00 | ≤2.00 | ≤0.045 | ≤0.030 | 2.00-3.00 | ≤1.00 | - | - | - | |

| 316L | 1.4404 | ≤0.030 | 16.00-18.00 | 10.00-14.00 | ≤2.00 | ≤0.045 | ≤0.030 | 2.00-3.00 | ≤1.00 | - | - | - | |

| 316Ti | 1.4571 | ≤0.08 | 16.00-18.00 | 10.00-14.00 | ≤2.00 | ≤0.045 | ≤0.030 | 2.00-3.00 | ≤1.00 | - | 0.1 | Ti5(C+N)~0.70 | |

| 317 | * | ≤0.08 | 18.00-20.00 | 11.00-15.00 | ≤2.00 | ≤0.045 | ≤0.030 | 3.00-4.00 | ≤1.00 | - | 0.1 | - | |

| 317L | 1.4438 | ≤0.03 | 18.00-20.00 | 11.00-15.00 | ≤2.00 | ≤0.045 | ≤0.030 | 3.00-4.00 | ≤1.00 | - | 0.1 | - | |

| 321 | 1.4541 | ≤0.08 | 17.00-19.00 | 9.00-12.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | Ti5(C+N)~0.70 | |

| 321H | * | 0.04-0.10 | 17.00-19.00 | 9.00-12.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | Ti5(C+N)~0.70 | |

| 347 | 1.4550 | ≤0.08 | 17.00-19.00 | 9.00-12.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | Nb≥10*C%-1.10 | |

| 347H | 1.494 | 0.04-0.10 | 17.00-19.00 | 9.00-12.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | Nb≥10*C%-1.10 | |

| xm-19 | Nitronic50 | ≤0.06 | 20.50-23.50 | 11.50-13.50 | 4.0-6.0 | ≤0.045 | ≤0.030 | 1.50-3.00 | ≤1.00 | - | 0.2-0.4 | Nb:0.10-0.30 V:0.10-0.30 | |

| 904L | N08904 | ≤0.02 | 19.0-23.0 | 23.0-28.0 | 4.0-5.0 | ≤0.045 | ≤0.035 | ≤1.00 | 0.1 | Cu:1.0-2.0 | |||

| Duplex | 2205 | S32205 | ≤0.03 | 22.0-23.0 | 4.5-6.5 | ≤2.00 | ≤0.030 | ≤0.020 | 3.0-3.5 | ≤1.00 | - | 0.14-0.20 | |

| 2507 | S32750 | ≤0.03 | 24.0-26.0 | 6.0-8.0 | ≤1.20 | ≤0.035 | ≤0.020 | 3.0-5.0 | ≤0.80 | 0.5 | 0.24-0.32 | ||

| * | S32760 | ≤0.03 | 24.0-26.0 | 6.0-8.0 | ≤1.00 | ≤0.030 | ≤0.010 | 3.0-4.0 | ≤1.00 | 0.5-1.00 | 0.2-0.3 | ||

| 2304 | S32304 | ≤0.03 | 21.5-24.5 | 3.0-5.5 | ≤2.50 | ≤0.040 | ≤0.030 | 0.05-0.6 | ≤1.00 | 0.05-0.6 | 0.05-0.2 | ||

| 329 | 1.4460 | ≤0.08 | 23.00-28.00 | 2.00-5.00 | ≤1.00 | ≤0.040 | ≤0.030 | 1.00-2.00 | ≤0.75 | - | - | ||

| Ferrite | 409 | S40900 | ≤0.03 | 10.50-11.70 | 0.5 | ≤1.00 | ≤0.040 | ≤0.020 | - | ≤1.00 | - | ≤0.030 | Ti6(C+N)~0.50 Nb:0.17 |

| 430 | 1Cr17 | ≤0.12 | 16.00-18.00 | - | ≤1.0 | ≤0.040 | ≤0.030 | - | ≤1.0 | - | - | - | |

| 446 | S44600 | ≤0.20 | 23.00-27.00 | 0.75 | ≤1.5 | ≤0.040 | ≤0.030 | 1.50-2.50 | ≤1.00 | - | ≤0.25 | - | |

| Martensite | 410 | 1Cr13 | 0.08-0.15 | 11.50-13.50 | 0.75 | ≤1.00 | ≤0.040 | ≤0.030 | - | ≤1.00 | - | - | - |

| 420 | 2Cr13 | ≥0.15 | 12.00-14.00 | - | ≤1.00 | ≤0.040 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 440C | 11Cr17 | 0.95-1.20 | 16.00-18.00 | - | ≤1.00 | ≤0.040 | ≤0.030 | 0.75 | ≤1.00 | - | - | - | |

We packs all U Tube bundles in bespoke wooden boxes and separate all U Tubes of different radii using finger pallets to facilitate easy assembly of bundles on receipt.

Any type of packing is available according to customer need to worldwide destinations.