Stainless U bend tubes

Stainless U bend tubes are made of stainless steel and are bent in a U-shape to redirect the flow of liquids or gases in a piping system.

SA 213 TP347H U bend tubes are seamless stainless steel boiler tubes.

SA213 TP347 / 347H is a seamless ferritic and austenitic alloy SS (Stainless Steel) boiler tube used in superheaters, and heat exchanger tubes.

SA 213 TP347H tubes are available in many shapes, including round, square, hollow, rectangular, hydraulic, coiled, straight, and "U" shape. The tubing sizes and thicknesses are usually 1/8 in. or 3.2 mm and inside diameter of 5 inch. The minimum wall thickness is 0.015 to 0.500 inch.

We can offer to customize service if customers have more stringent requirements on capillary dimensional accuracy and surface finish, including stainless steel bright annealed pipe,

SA 213 TP347H is a seamless, ferritic and austenitic alloy stainless steel tube. It is used in superheaters and heat exchanger tubes. It can be used in high temperature and high pressure environments.

ASTM A213 ASME SA-213 TP347H Seamless Steel Tubes contains NB-Cr-Ni austenitic stainless steel. Because of the stable element Nb, it has good intergranular corrosion resistance, high endurance strength and oxidation resistance, as well as good technological properties such as bending and welding. Its comprehensive performance is better than ASTM A213 ASME SA-213 TP304H

SA213 TP347 / 347H is a seamless ferritic and austenitic alloy SS (Stainless Steel) boiler tube used in superheaters, and heat exchanger tubes.

TP347H is a stabilized austenitic stainless steel that is used in reheaters, heat exchangers, and superheaters. It is a corrosion-resistant material with a high creep strength. The high carbon content of TP347H gives it extra toughness. The chemical composition of TP347H includes: Silicon, Chromium, Nickel, Columbium +Tantalum.

TP347H has been used as the material of tubes in 600°C USC power plants in China. It can be easily elongated by 40%.

347H is the higher carbon version of 347 plate. Due to the additional carbon present in 347H plate, it is tougher and generally more durable than 347 plate. These grades of stainless steel plate is available in a wide range of sizes at Penn Stainless Products.

This grade of stainless steel has an elongation of 40%. On the Brinell hardness scale 347 and 347H stainless steel plate has hardness of 201 and on the Rockwell B scale, both 347 and 347H have a hardness of 95.

Both contain between 17.0% and 20.0% chromium, and no more than 2.0% manganese. They are made of between 9.0% and 13.0% nickel. 347 stainless steel plate contains at most 0.04% phosphorous while 347H stainless steel can only contain up to 0.03% phosphorous.

| Grade | UNS | Composition, % | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Design | C | Mn | P | S | Si | Cr | Ni | Mb | Ti | Nb | N | Cu | Ce | B | Al | |

| TP347 | S34700 | 0.08 | 2 | 0.045 | 0.03 | 1 | 17.0–19 | 9.0–13 | . . . | . . . | See Spec | . | . | |||

| TP347H | S34709 | 0.04 – 0.1 | 2 | 0.045 | 0.03 | 1 | 17.0–19 | 9.0–13 | . . . | . . . | See Spec | . | . | . . | ||

| Grade | UNS | Heat Treat Type | Austenitizing/ Solutioning Temperature, min or range °F [°C] | Cooling Media | ASTM Grain Size No. B |

|---|---|---|---|---|---|

| Designation | |||||

| TP347 | S34700 | Solution treatment | 1900 °F [1040 °C] | water or another rapid cool | . . . |

| TP347H | S34709 | Solution treatment | cold worked:2000 | water or another rapid cool | 7 |

| [1100] hot rolled: 1925 [1050]H |

| Grade | UNS | Tensile Strength, Min ksi [MPa] | Yield strength, min ksi [MPa] | Elongation in 2 in. or 50 mm, min, %A, B | Hardness, Max | |

|---|---|---|---|---|---|---|

| Designation | Brinell/Vickers | Rockwell | ||||

| TP347 | S34700 | 75 [515] | 30 [205] | 35 | 192HBW/200Hv | 90HB |

| TP347H | S34709 | 75 [515] | 30 [205] | 35 | 192HBW/200Hv | 90HB |

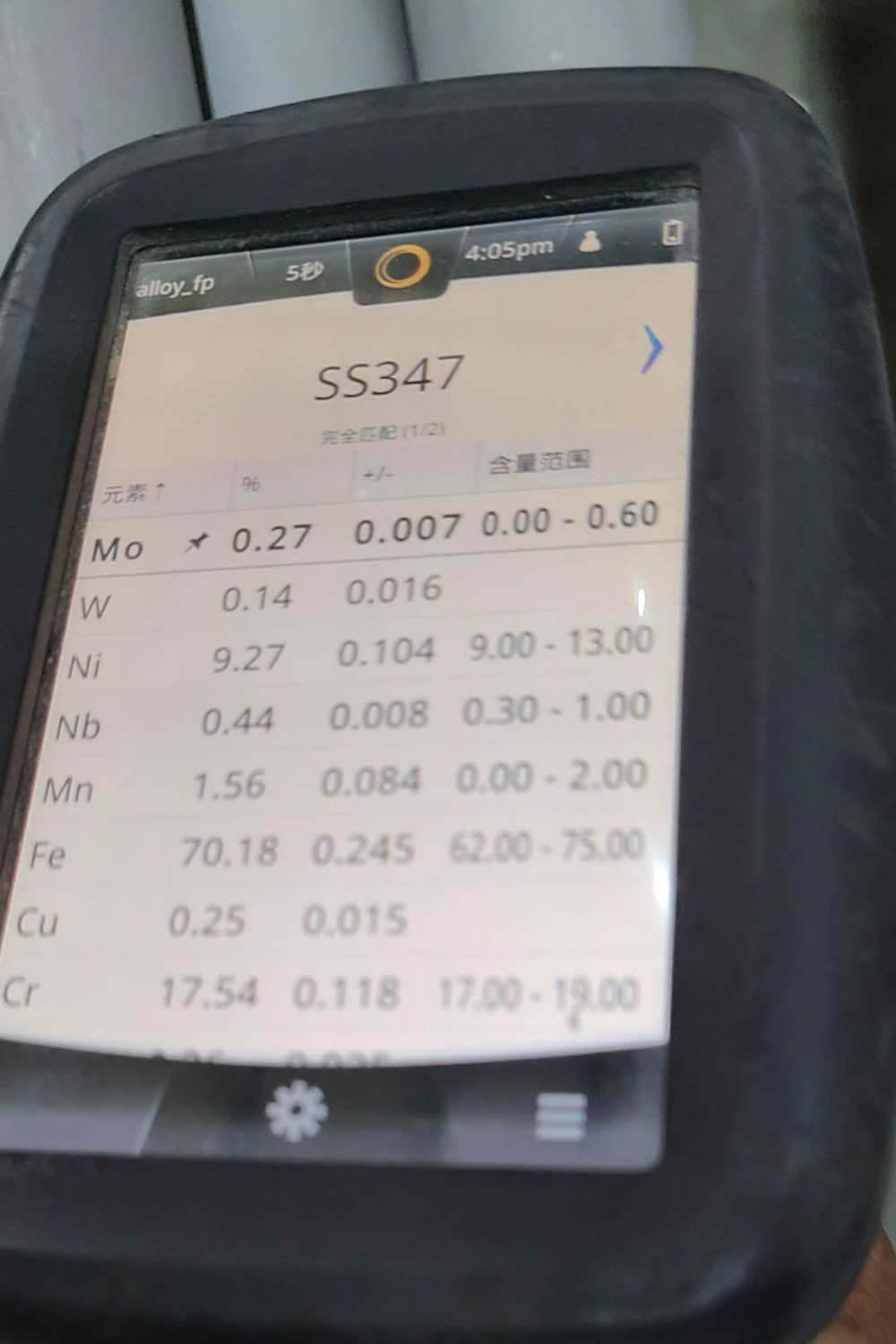

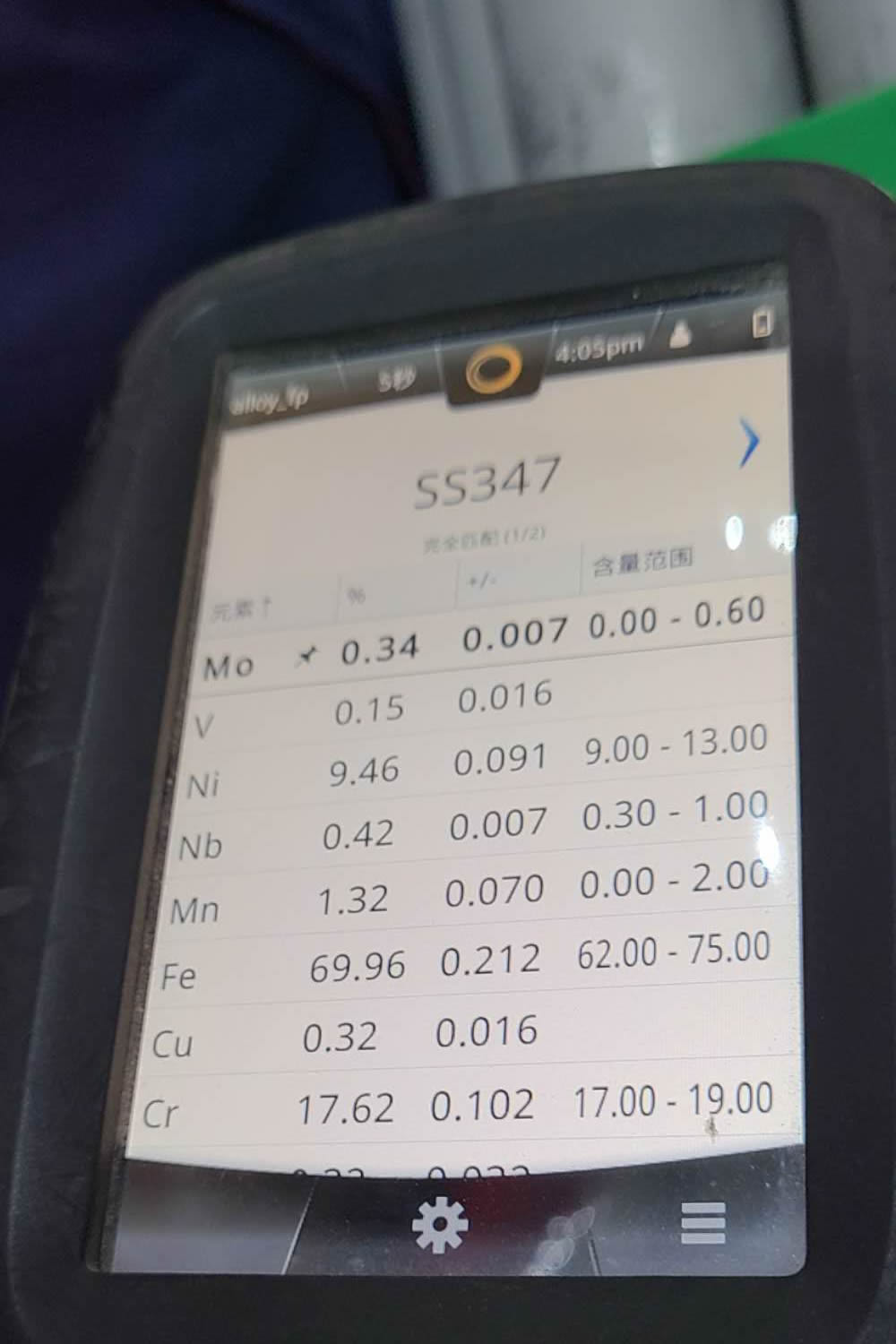

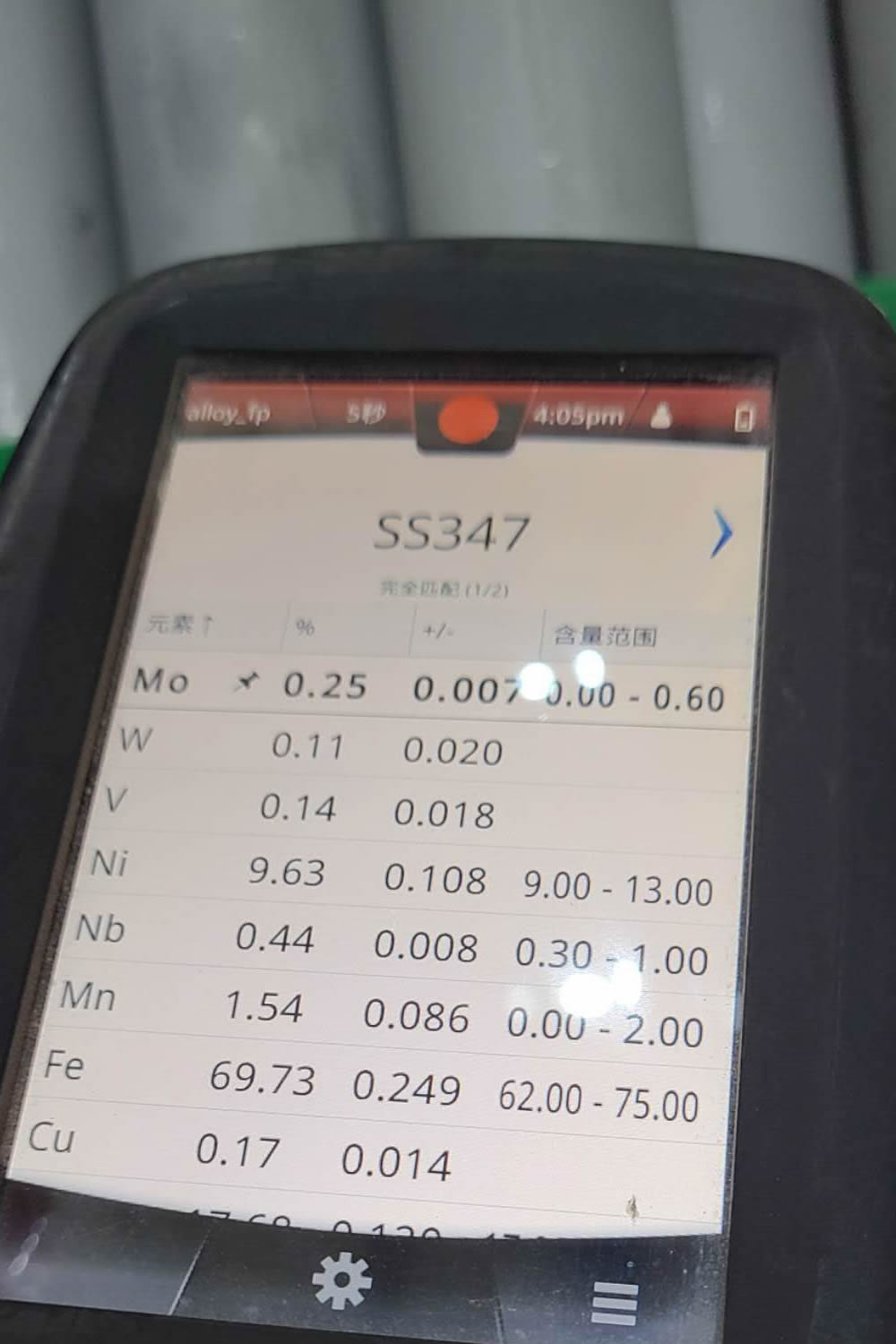

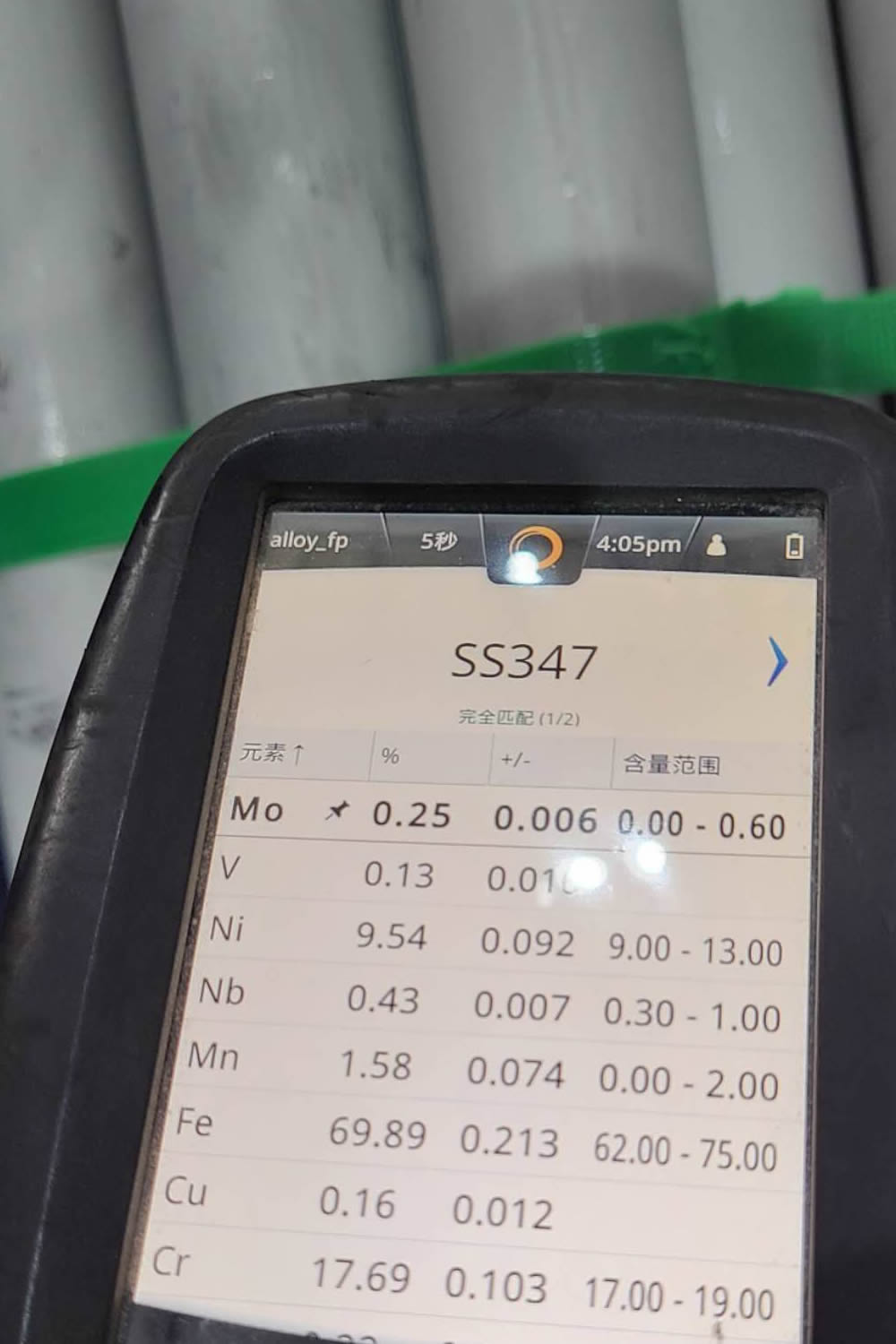

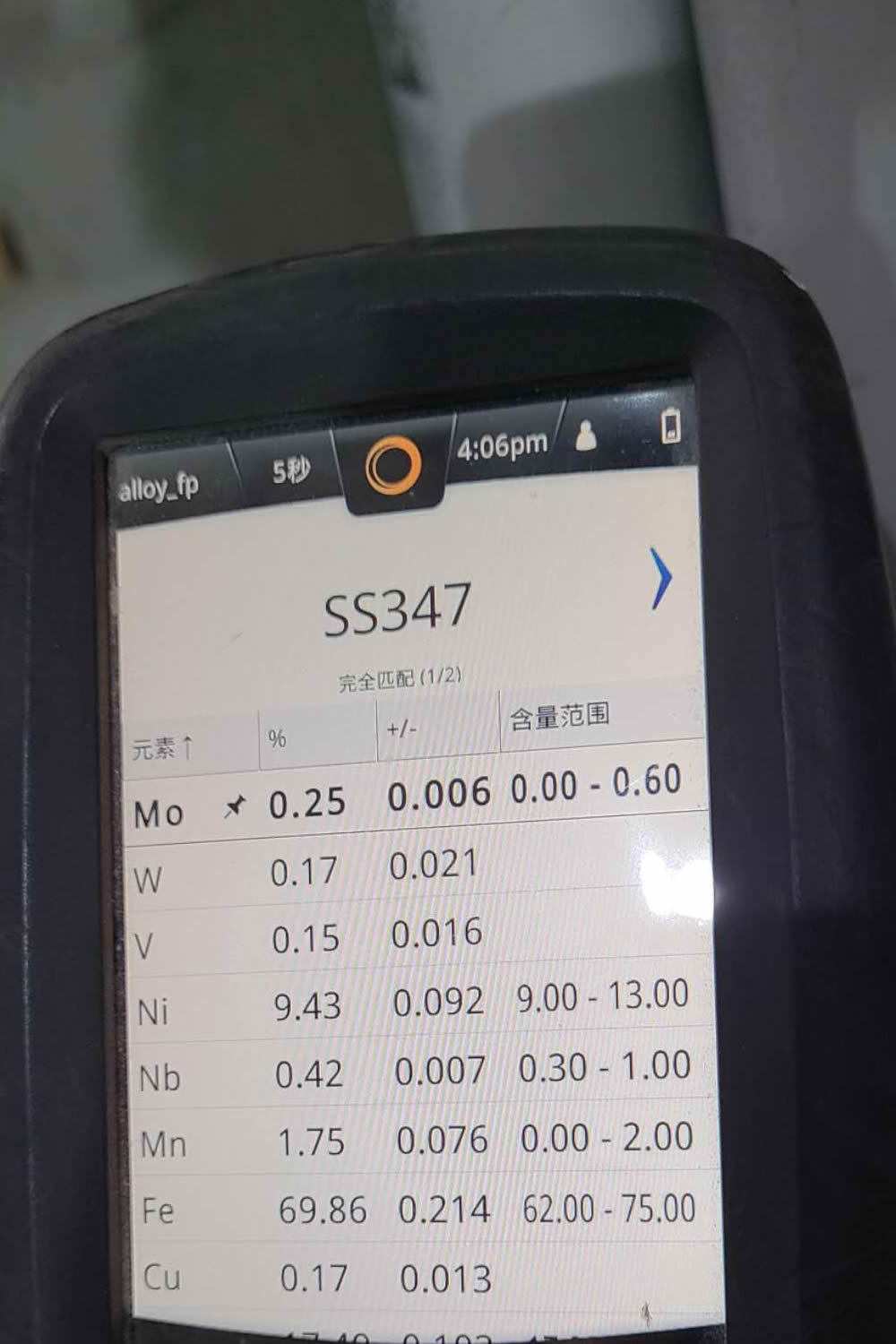

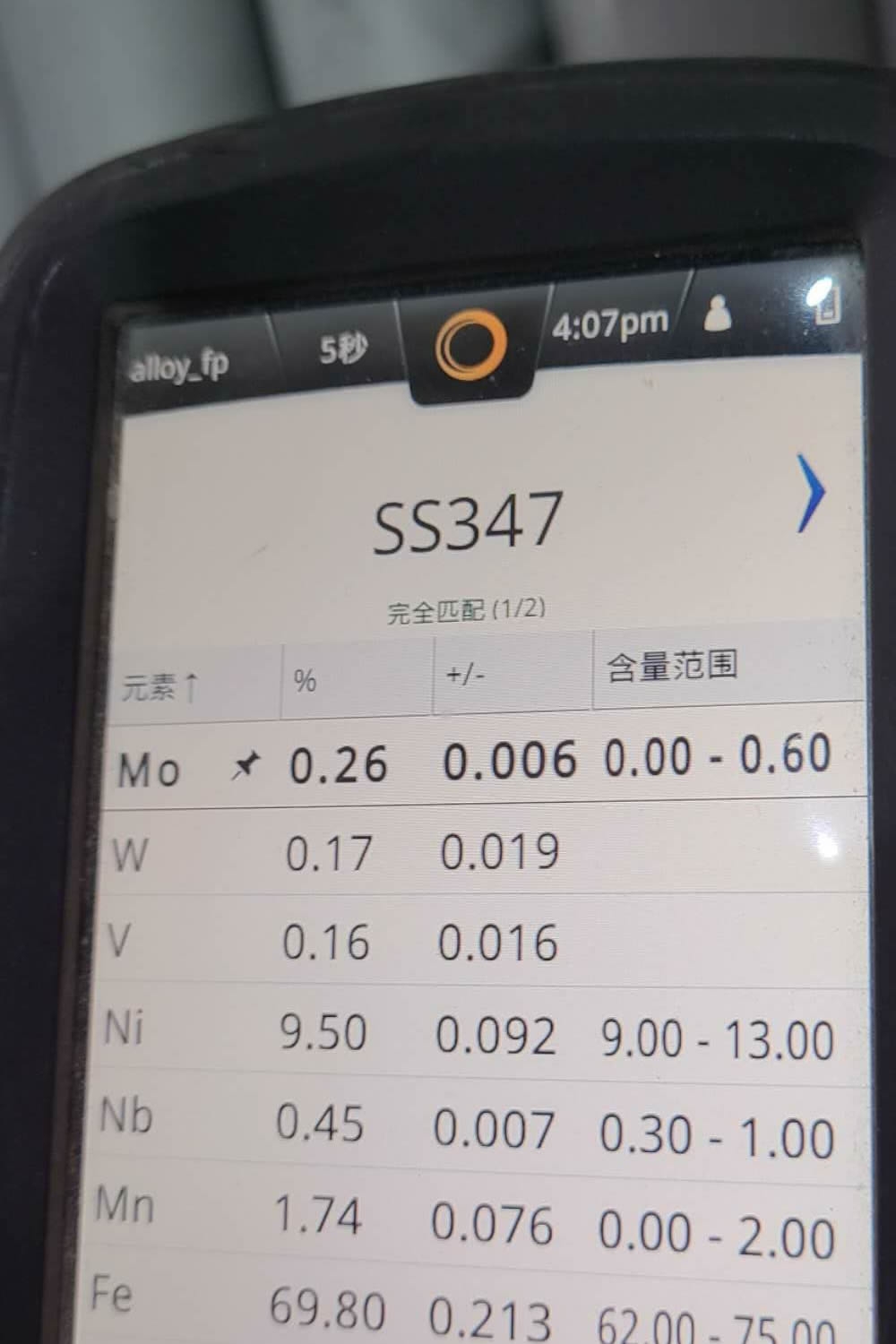

Positive Material Identification (PMI) testing for TP347H involves the analysis of the chemical composition of the material to verify its alloy content and ensure it meets the required specifications.

TP347H is a high-temperature stainless steel alloy often used in applications like boiler tubes and heat exchangers. PMI testing is crucial to confirm that the material is indeed TP347H and that it meets the necessary alloy composition standards.

| Grade | UNS No | Euronorm | |

|---|---|---|---|

| No | |||

| 347H | S34709 | 1.4961 | |

| Specification | Allowable Outside Diameter Variation in mm | Allowable Wall Thickness Variation | Exact Length Tolerance in mm | Testing | ||||

|---|---|---|---|---|---|---|---|---|

| Nominal Diameter | Over | Under | %Over | %Under | Over | Under | ||

| ASTM-A213 TP347H Seamless Boiler Superheater and Heat Exchanger Tubes |

Under 25.4 | .1016 | .1016 | +20 | -0 | 3.175 | 0 | Flattening Test |

| 25.4-38.1 incl | .1524 | .1524 | +22 | -0 | 3.175 | 0 | Tension Test | |

| 38.1-50.8 excl | .2032 | .2032 | +22 | -0 | 3.176 | 0 | Flare Test | |

| 50.8-63.5 excl | .254 | .254 | +2 | -0 | 4.46 | 0 | Hardness Test | |

| 63.5-76.2 excl | .347H8 | .347H8 | +22 | -0 | 4.76 | 0 | 100% Hydrostatic test | |

| 76.2-101.6 incl | .381 | .381 | +22 | -0 | 4.76 | 0 | Refer to ASTM A-450 | |

Flattening tests shall be made on specimens from each end of one finished tube, not the one used for the flaring test, from each lot.

Flaring tests shall be made on specimens from each end of one finished tube, not the one used for the flattening test, from each lot.

Each TP347H Stainless Steel Seamless pipe shall be subjected to the nondestructive electric test or the hydrostatic test. The type of test to be used shall be at the manufacturer’s option unless otherwise specified in the purchase order.

347 and 316 stainless steel both fall into the 300-series family and are known for their stability. While 316 is a standard alloy that offers superior weldability, 347 offers superior corrosion resistance and mechanical strength.

Markings will adhere to prescribed specifications in A999/A999M. They shall include the NPS or OD and schedule number or average wall thickness, heat number, and NH (when hydro testing is not performed) and ET (when eddy-current testing is performed) or UT (when ultrasonic testing is performed). The marking shall also include the manufacturer’s private identifying mark, the marking requirement of section 12.3 on Hydrostatic or Nondestructive Electric Test, if applicable, and whether seamless (SML), welded (WLD), or heavily cold-worked (HCW). For Grades TP347 and TP347H Stainless Tubes, the marking shall also include the heat number and heat-treatment lot identification.

ASTM A213 TP347H is a high-temperature resistant austenitic stainless steel that is commonly used in applications where high temperatures and corrosive environments are present. Some of the common applications of ASTM A213 TP347H include:

U-bend tubes are used to transfer heat between fluids. They can return the flow of coolants/fluids at 180 degrees in a much smaller space.

The common application fields are: heat exchangers (condensers, evaporators, sea water desalinators) chemical and petrochemical industries. food processing and refrigeration industries.

Heat-exchanger equipment on the basis of seamless stainless U-tubes is essential in strategically important and critical fields — nuclear and petrochemical machine building.

Fin tubes are used in applications involving the transfer of heat from a hot fluid to a colder fluid through a tube wall. Furthermore, finned tubes are used when the heat transfer coefficient on the outside of the tubes is appreciably lower than that on the inside.

As the pipes warm up they expand, the bend allows this expansion to proceed without buckling the pipes. Alternatively, flexible or sliding types of expansion provision are available, and large pipes are mounted on rollers.

With strong wood structure box packing by containers loading and shipping.

We packs all U Tube bundles in bespoke wooden boxes and separate all U Tubes of different radii using finger pallets to facilitate easy assembly of bundles on receipt.

Any type of packing is available according to customer need to worldwide destinations.